Concrete in mixed radius shale ceramisite lightweight aggregate structure and preparation method thereof

A technology of shale ceramsite and lightweight aggregate, which is applied in the field of building materials, can solve the problems of heat preservation and energy saving effects, but there are few researches, and achieve the effects of widening the scope of use, good fluidity, and high thermal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

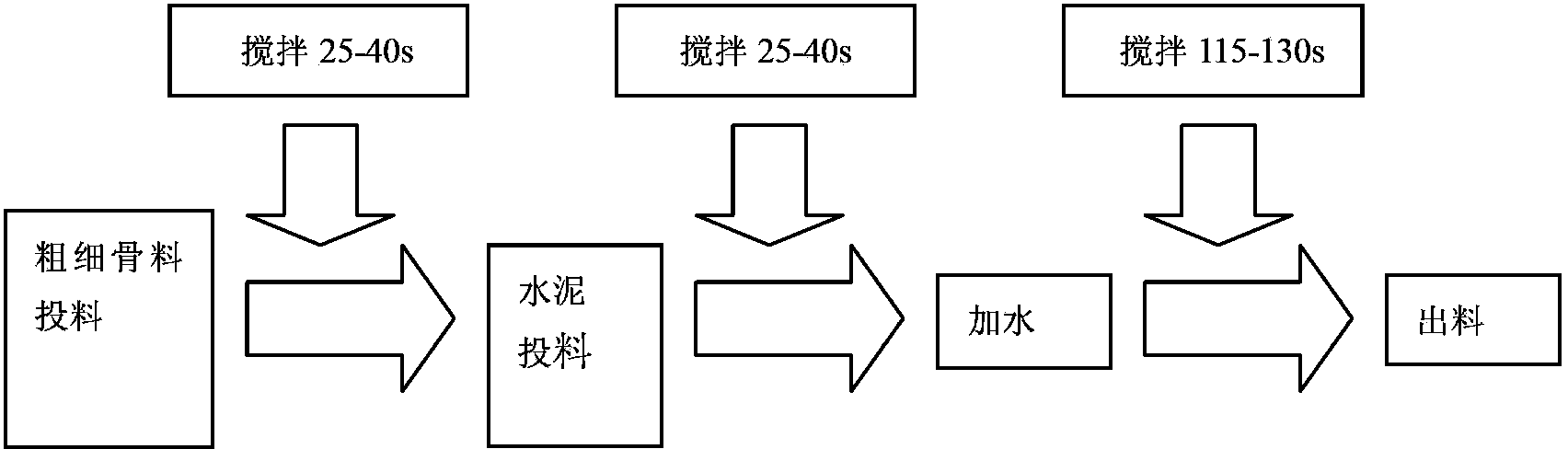

Method used

Image

Examples

Embodiment 1

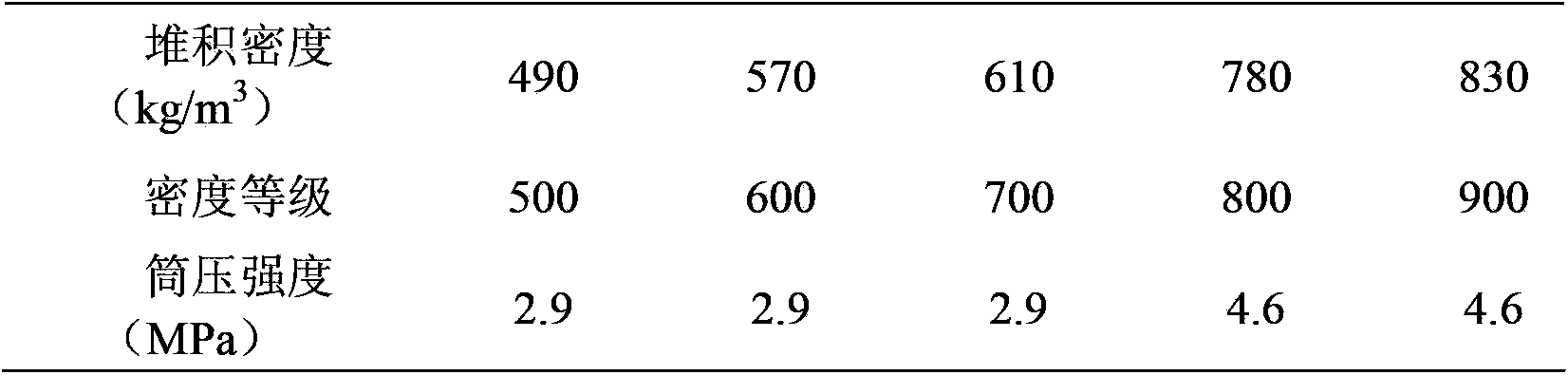

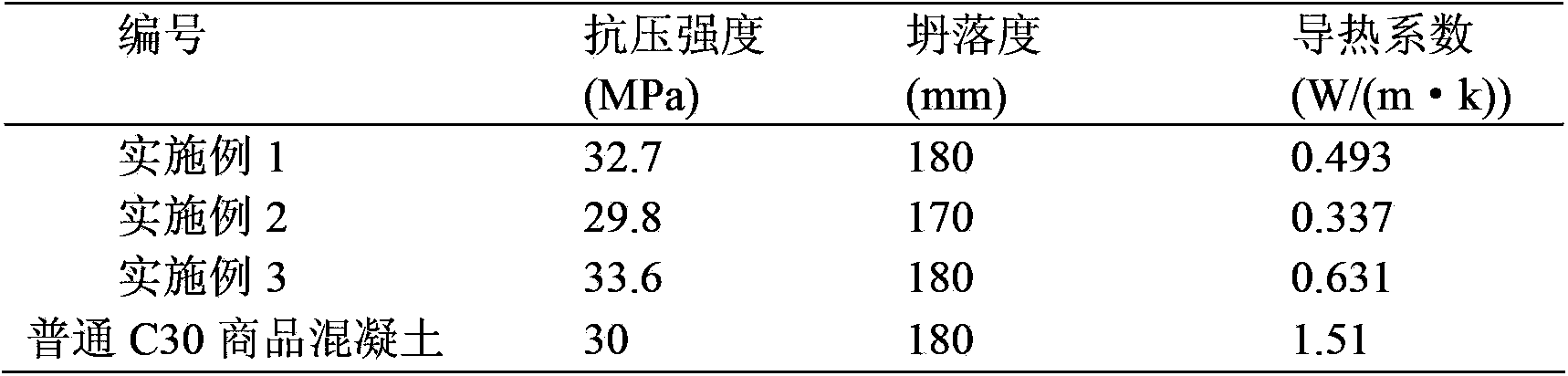

[0018] The ceramsite lightweight aggregate concrete in this example consists of the following components and weight ratio (kg / m 3 ) composition: cement 450kg / m 3 , water 180kg / m 3 , dry sand 878kg / m 3 , five different particle sizes mixed ceramsite 504kg / m 3 (The bulk density is 490kg / m 3 、570kg / m 3 、610kg / m 3 、780kg / m 3 、830kg / m 3 The ceramsite is mixed according to the mass ratio of 2:5:3:2:3 to form a bulk density of 680kg / m 3 mixed ceramsite).

[0019] The raw material ceramsite is spherical shale ceramsite, which consists of five kinds of ceramsite with different particle sizes (see Table 1 for the bulk density of the five kinds of ceramsite used). : 3 mass ratio for mixing, the bulk density of ceramsite after mixing is 680kg / m 3 , apparent density 1120kg / m 3 , porosity 39%, cylinder compressive strength 3.3MPa, water absorption 9.2%, the evaluation result is 700 grade, first-class product. After mixing spherical ceramsite with different particle sizes, it hel...

Embodiment 2

[0030] The ceramsite lightweight aggregate concrete in this example consists of the following components and weight ratio (kg / m 3 ) composition: cement 420kg / m 3 , water 170kg / m 3 , dry sand 835kg / m 3 , mixed ceramsite 504kg / m 3 , the preparation steps are the same as those of Example 1.

Embodiment 3

[0032] The ceramsite lightweight aggregate concrete in this example consists of the following components and weight ratio (kg / m 3 ) composition: cement 500kg / m 3 , water 200kg / m 3 , dry sand 920kg / m 3 , mixed ceramsite 504kg / m 3 , the preparation steps are the same as those of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com