Treatment method of pressed sesame oil

A technology of pressing sesame oil and treatment methods, which is applied in the direction of edible oil/fat, fat oil/fat refining, fat production, etc., and can solve the problems of a large amount of waste water, waste residue, difficult treatment, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

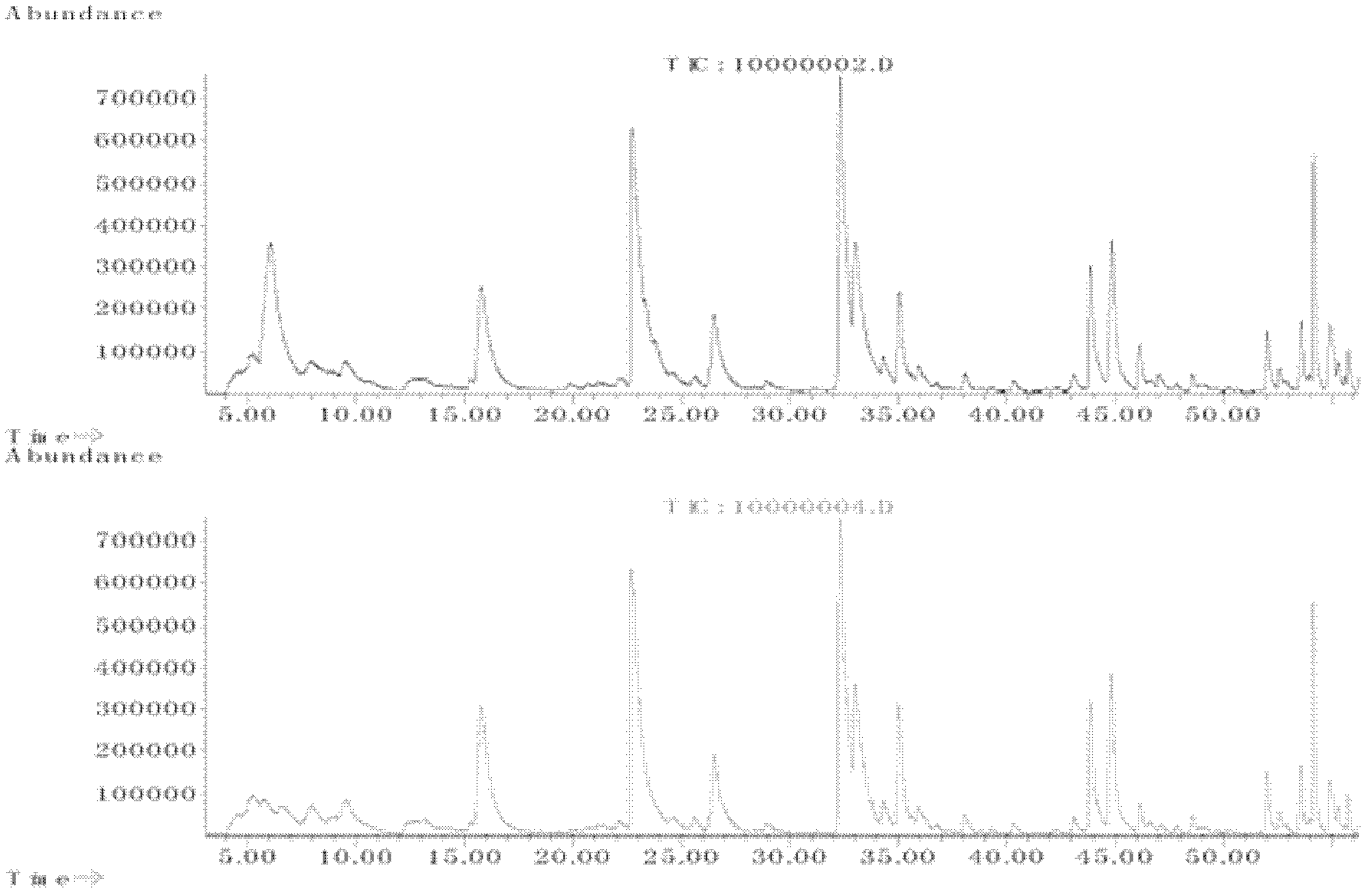

Image

Examples

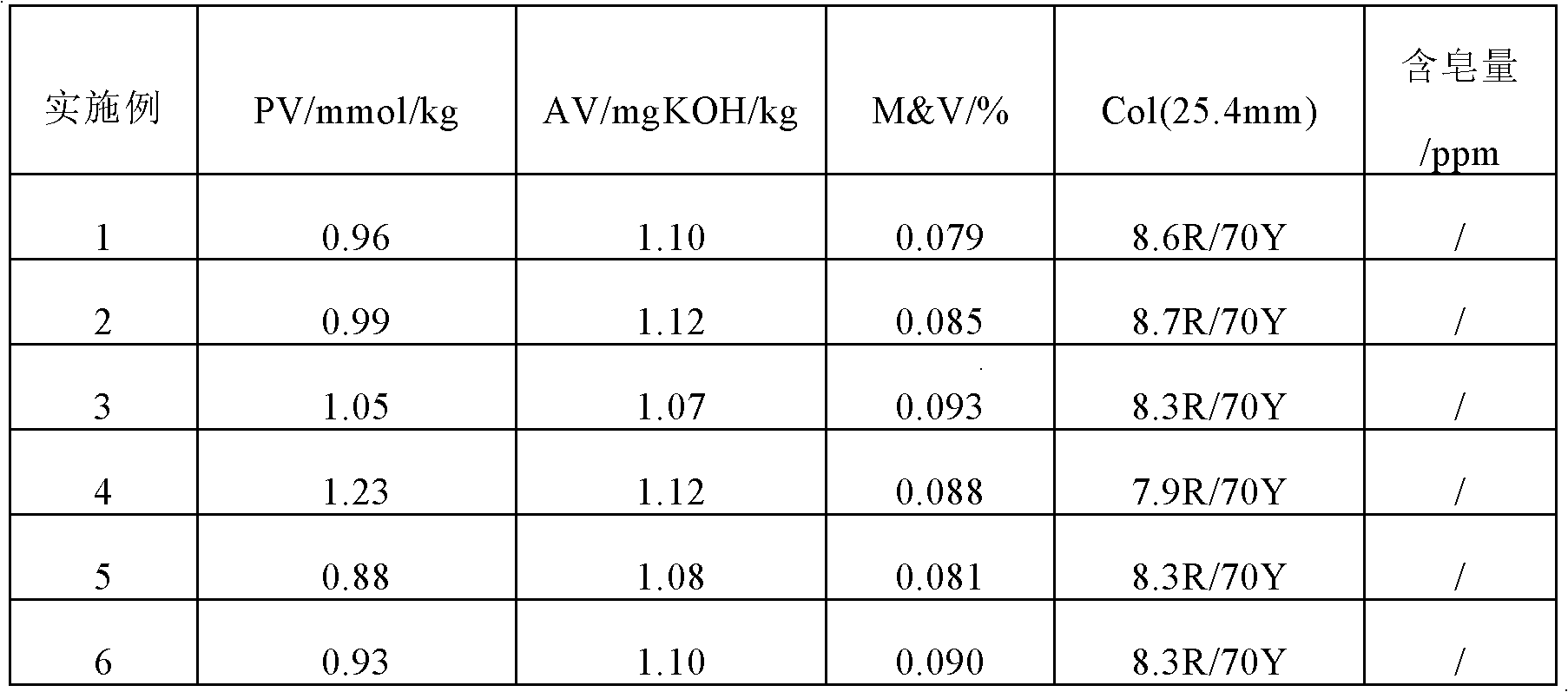

Embodiment 1

[0107]Roast and press sesame seeds to obtain sesame oil, filter while hot at 60°C, take 200g of sesame oil, add 10g of phosphate buffer solution with a concentration of 0.4mol / L and a pH of 7.0, stir at 70°C for 30min, centrifuge at 4000rpm for 10min, and take The upper layer oil samples were filtered and dried for 10 minutes, then sensory evaluation and physical and chemical indicators were determined. Preparation of phosphate buffer: weigh NaH 2 PO 4 19.0 g, Na 2 HPO 4 13.9g (disodium hydrogen phosphate), dissolved in water, and then diluted to 500mL.

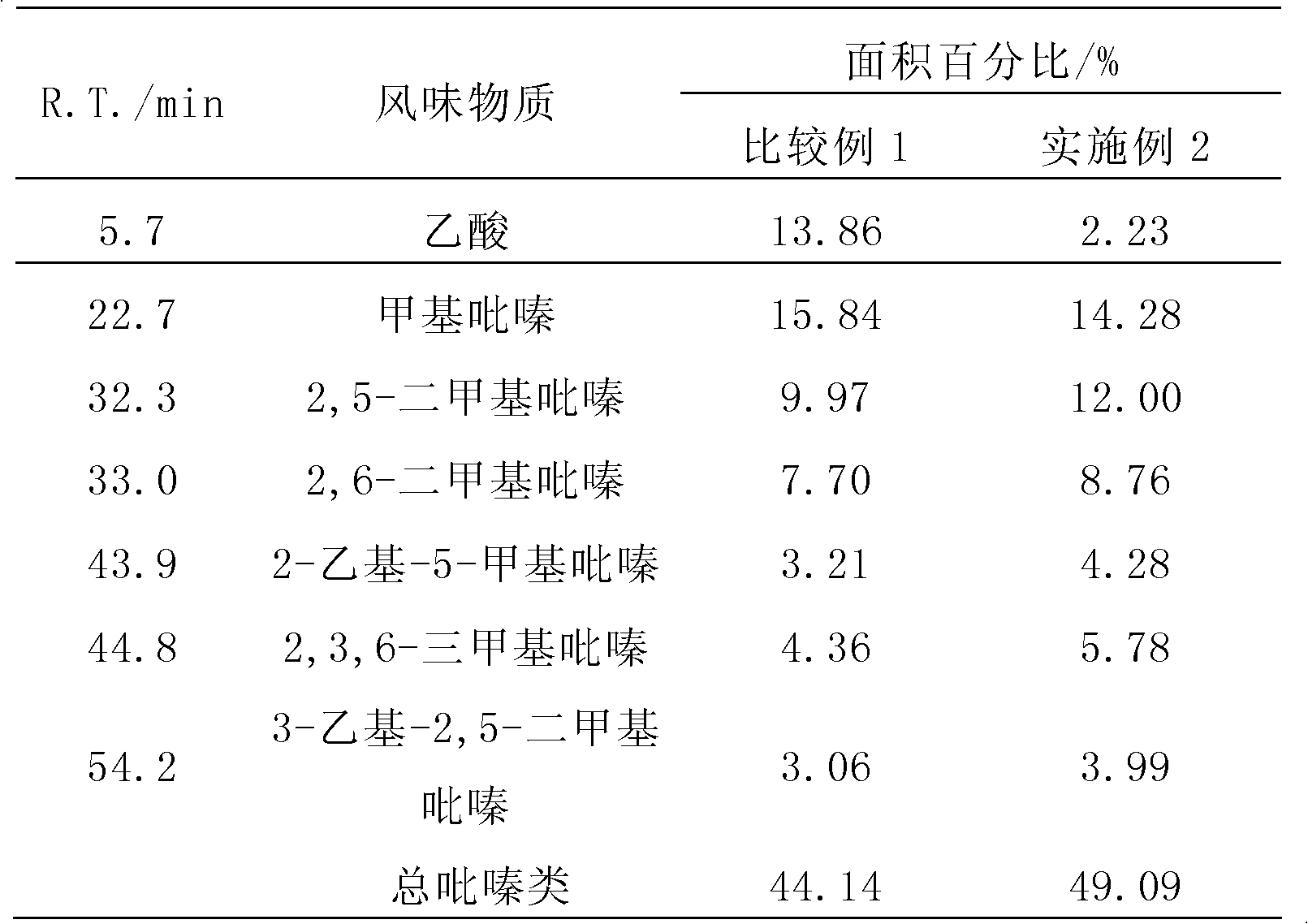

Embodiment 2

[0109] Roast and press sesame seeds to obtain sesame oil, filter while hot at 50°C, take 200g of sesame oil, add 20g of phosphate buffer solution with a concentration of 0.2mol / L and a pH of 7.5, stir at 25°C for 60min, centrifuge at 4000rpm for 10min, and take the upper layer The oil sample was filtered and dried for 30 minutes, and the sensory evaluation and physical and chemical indicators were determined. The preparation method of the phosphate buffer is as described in Example 1, and the amount of sodium dihydrogen phosphate and disodium hydrogen phosphate is adjusted according to concentration and pH (phosphate is added on the base solution in Example 1).

Embodiment 3

[0111] Roast and press sesame seeds to obtain sesame oil, filter while hot at 40°C, take 200g sesame oil, add 30g phosphate buffer, the buffer concentration is 0.1mol / L, pH is 8.0, stir at 50°C for 30min, and centrifuge at 4000rpm for 10min Afterwards, take the upper oil sample, filter it, and dry it for 30 minutes for sensory evaluation and determination of physical and chemical indicators. The preparation method of the phosphate buffer is as described in Example 1, and the amount of sodium dihydrogen phosphate and disodium hydrogen phosphate is adjusted according to concentration and pH (sodium phosphate salt is added to the base solution in Example 1).

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap