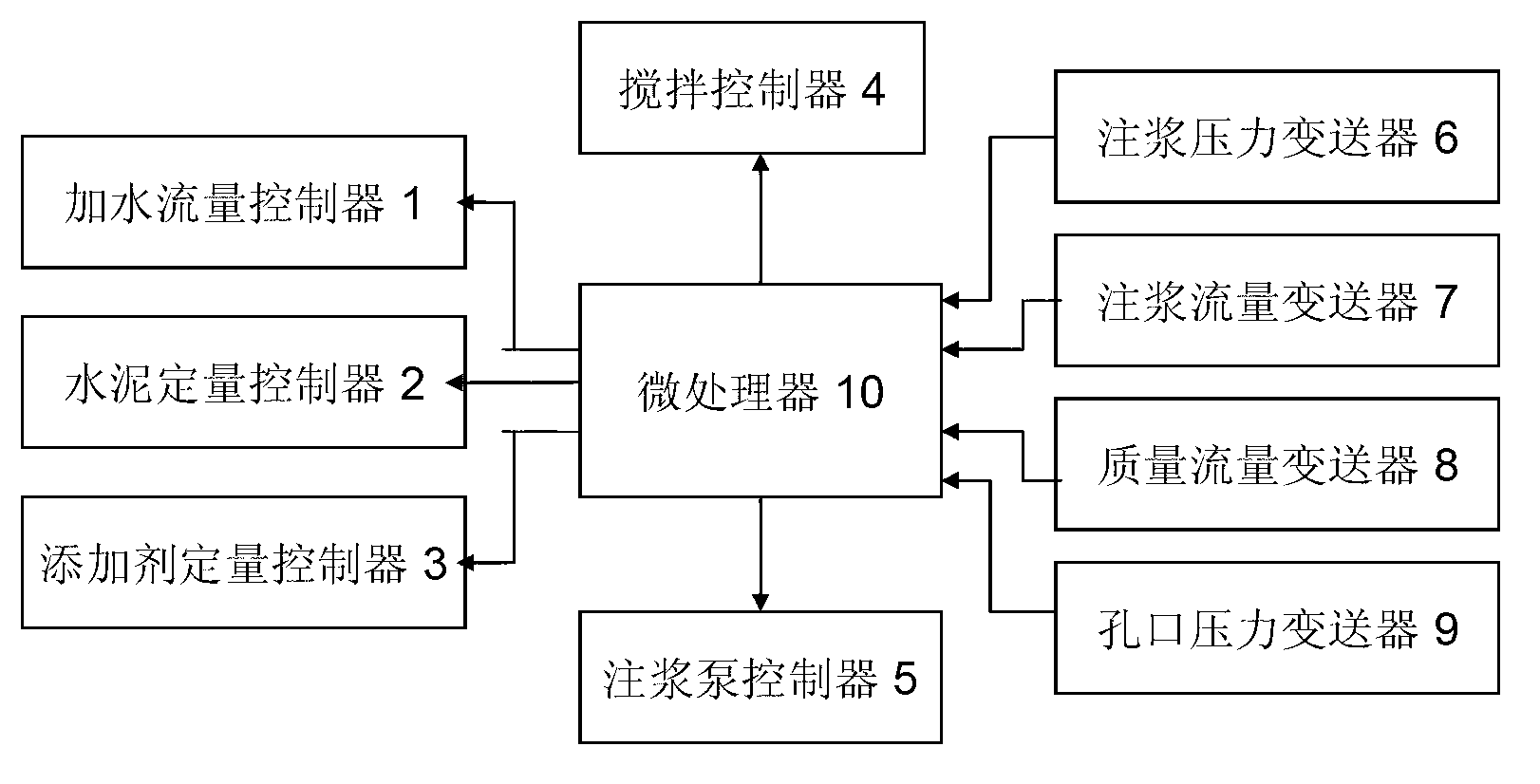

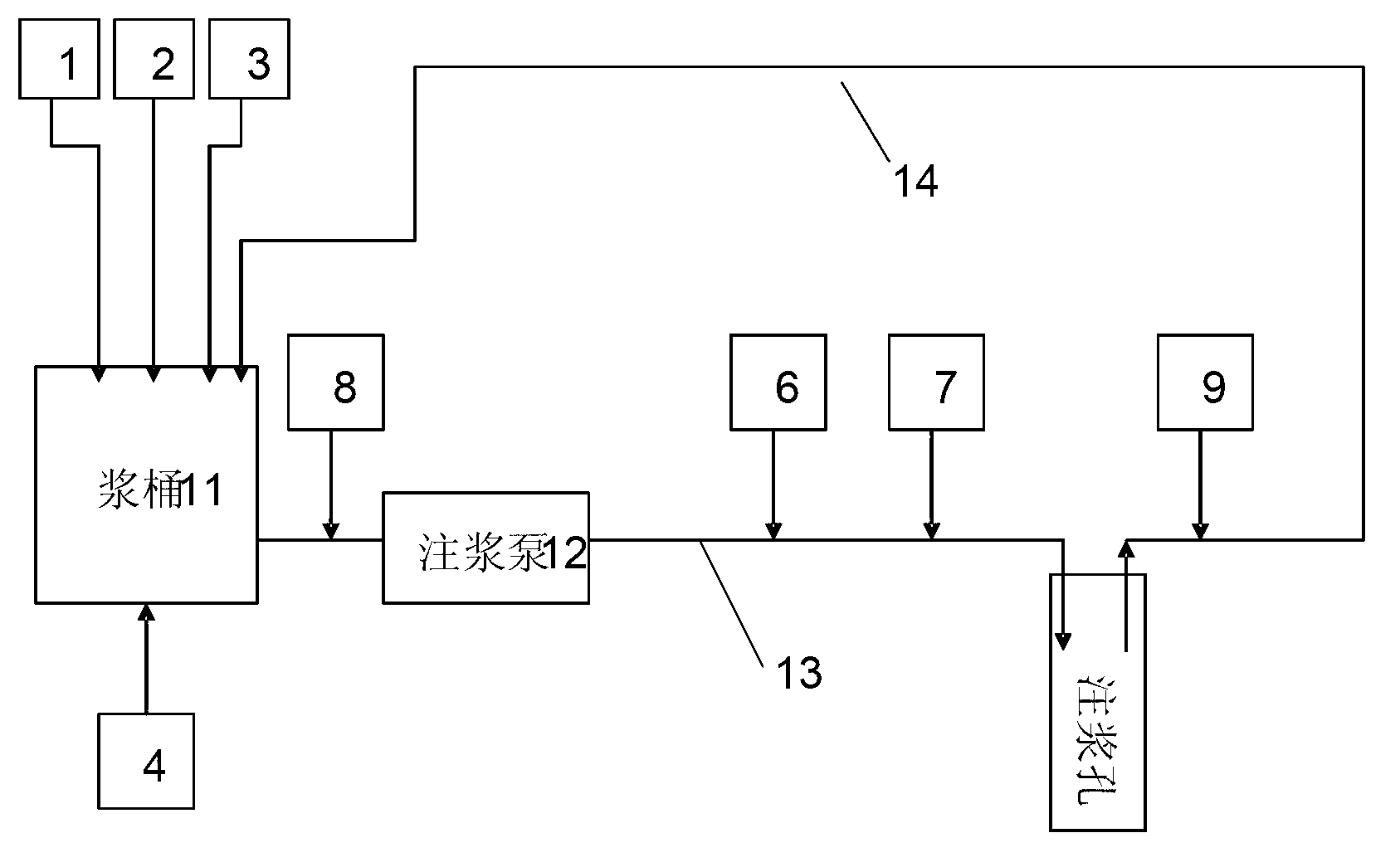

Automatic grouting control method and device

An automatic control device and grouting technology, applied in the direction of non-electric variable control, comprehensive factory control, comprehensive factory control, etc., to achieve good effect, convenient use and wide practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0021] The steps of the grouting automatic control method of the present invention are as follows,

[0022] Step 1, the control of the initial injection stage:

[0023] After the device is started, the microprocessor 10 controls the cement quantitative controller 2 and the additive quantitative controller 3 to put cement and additives into the slurry tank 11 according to the preset input parameters, and then the microprocessor 10 controls the water flow controller 1 to inject the slurry into the slurry tank 11. The pre-set amount of water is injected into the barrel 11, and at the same time, the microprocessor 10 sends instructions to the stirring controller 4, and the stirring controller 4 controls the slurry barrel 11 to stir the internal materials, and the mass flow transmitter 8 is connected to the slurry barrel 11. The density of the slurry is detecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com