Diode encapsulation method

A packaging method and diode technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of high consumption of human resources, low production efficiency, and the impact of diode products, so as to improve processing efficiency and reduce manual intervention. , the effect of consistency guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The diode packaging method in this embodiment is used for attaching the diode chip between the upper and lower sheets of the diode, and the method includes the following steps:

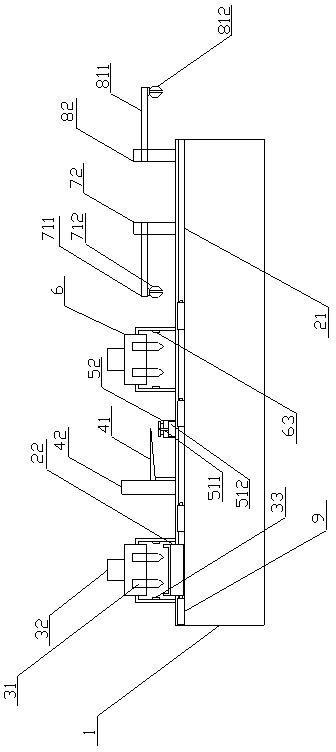

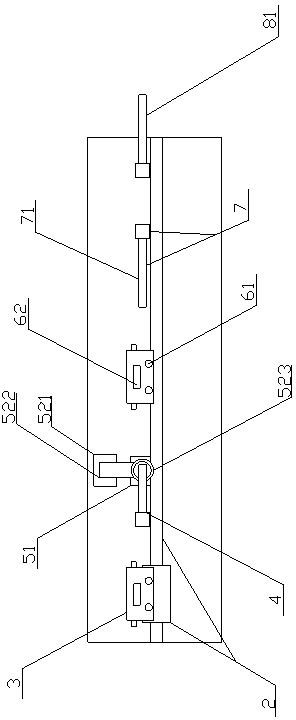

[0035] 1) as Figure 1-2As shown in the figure, a first glue dispensing mechanism 3 , a crystal bonding mechanism 4 , a second glue dispensing mechanism 6 and a mechanical arm mechanism 7 are sequentially arranged on a machine base 1 to form a plurality of workstations. A crystal supply mechanism is arranged on the side;

[0036] 2) Place the blank sheet on a conveying unit 2, and the conveying unit 2 transports the blank sheet to the station of the first glue dispensing mechanism 3 through the drive of a driving unit, and the first glue dispensing mechanism 3 is used to unload the material. On-chip dispensing operations;

[0037] 3) Continue to transport the dispensed blanks to the station of the die-bonding mechanism 4 through the above-mentioned conveying unit 2 and the driving unit. At t...

Embodiment 2

[0054] Others are the same as those described in Embodiment 1, except that the swing arm driving device 42 is a decoupling direct drive device, which includes a rotary direct drive device, a linear direct drive device and a spline mechanism. The mechanism includes a spline shaft (or external spline) and a spline nut (or internal spline), and one of the rotating parts of the rotary direct drive device and the linear motion parts of the linear direct drive device is connected to the spline shaft And move synchronously, the other one is connected with the spline nut and moves synchronously.

[0055] The beneficial effects of the above embodiment are:

[0056] 1) In the present invention, a first glue dispensing mechanism, at least one die-bonding mechanism, a second glue dispensing mechanism and at least one manipulator mechanism are sequentially arranged on a machine base to form multiple stations, and at the same time, at least one A crystal supply mechanism, which places the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com