Diode packaging equipment

A technology for packaging equipment and diodes, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., to solve problems such as inconsistent placement, worker influence, and high human resource consumption, reducing manual intervention, stabilizing processing efficiency, The effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

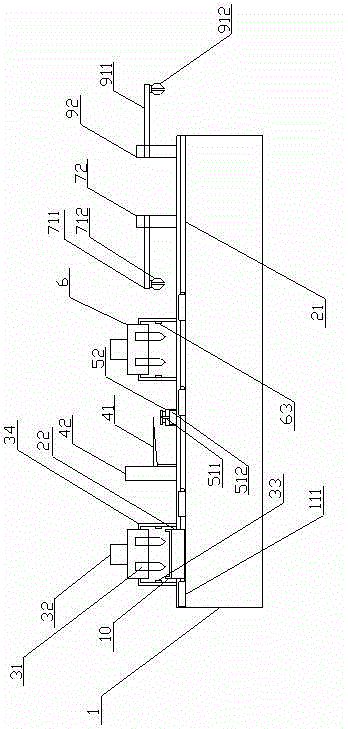

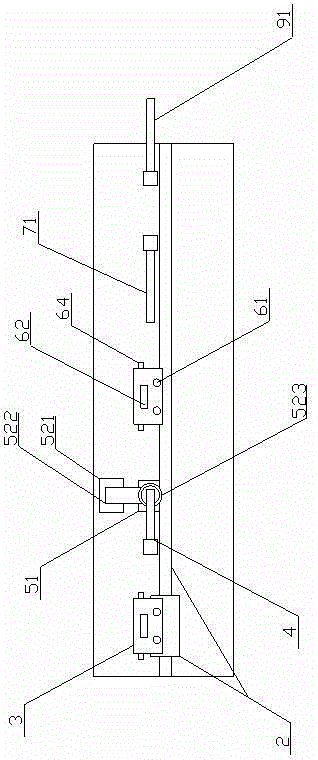

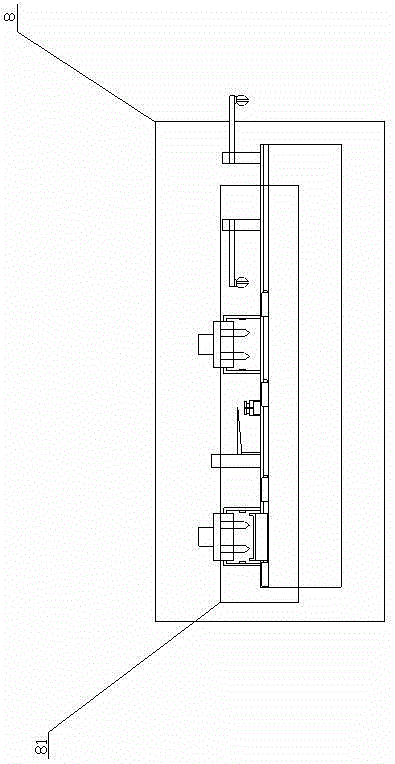

[0043] Such as figure 1 , figure 2 As shown, the diode packaging equipment in this embodiment includes: a machine base 1; a conveying mechanism 2, which is slidably connected to the machine base 1; a driving mechanism, which is arranged on the machine base 1, and is used to drive the conveying mechanism 2 to reach multiple station; the first dispensing mechanism 3, which is arranged on one end of the support 1, above the direction of movement of the conveying mechanism 2, the first dispensing mechanism 3 includes two first dispensing heads 31; the solid crystal mechanism 4, which It is arranged on the machine base 1 and above the moving direction of the conveying mechanism 2. The crystal-bonding mechanism 4 includes a crystal-bonding swing arm 41 and a swing-arm driving device 42 for driving the crystal-bonding swing arm 41. One end of the crystal-bonding swing arm 41 is also It is rotatably connected with the machine base 1, and the swing arm drive device 42 is implemented ...

Embodiment 2

[0059] Others are the same as those described in Embodiment 1, except that the swing arm driving device 42 is a decoupled direct drive device, which includes a rotary direct drive device, a linear direct drive device and a spline mechanism, and the spline The mechanism includes a spline shaft (or external spline) and a spline nut (or internal spline), and the rotating part of the rotary direct drive device is connected to the spline shaft with one of the linear moving parts of the linear direct drive device And move synchronously, the other one is connected with the spline nut and moves synchronously.

[0060] The working principle of the present invention is introduced below:

[0061] Place the lower material of the diode on the conveying mechanism 2, driven by the driving mechanism, the conveying mechanism 2 transports the lower material to the station of the first dispensing mechanism 3 for dispensing, and the dispensing is completed The unloading sheet continues to be tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com