Balanced micro-strip line feeding printed V-shaped antenna with loading metal disc

A technology for balancing microstrip lines and metal discs, applied to antennas, resonant antennas, electrical components, etc., can solve the problems of complex feeding structure and loss, and achieve the effect of improving gain characteristics, small size, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

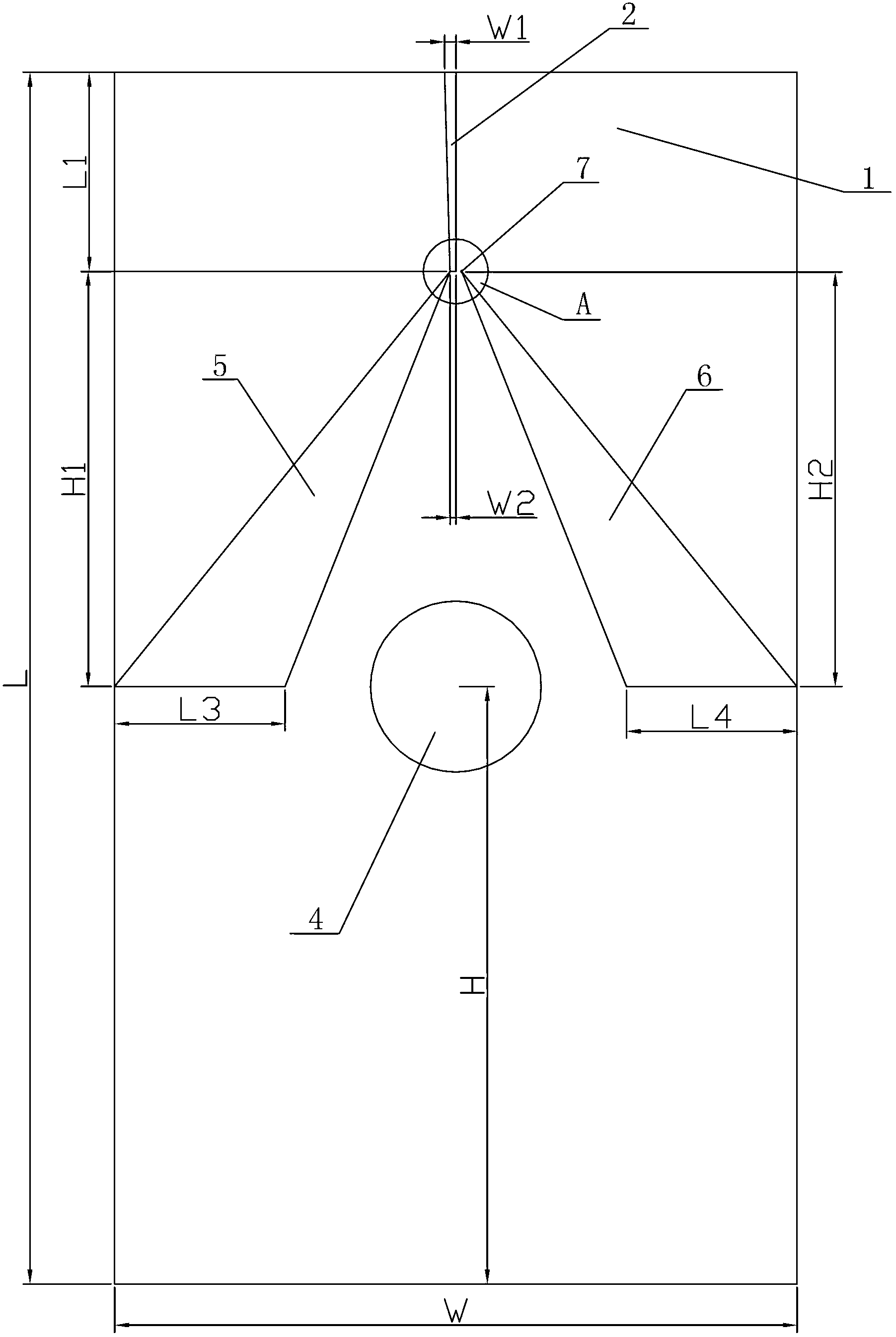

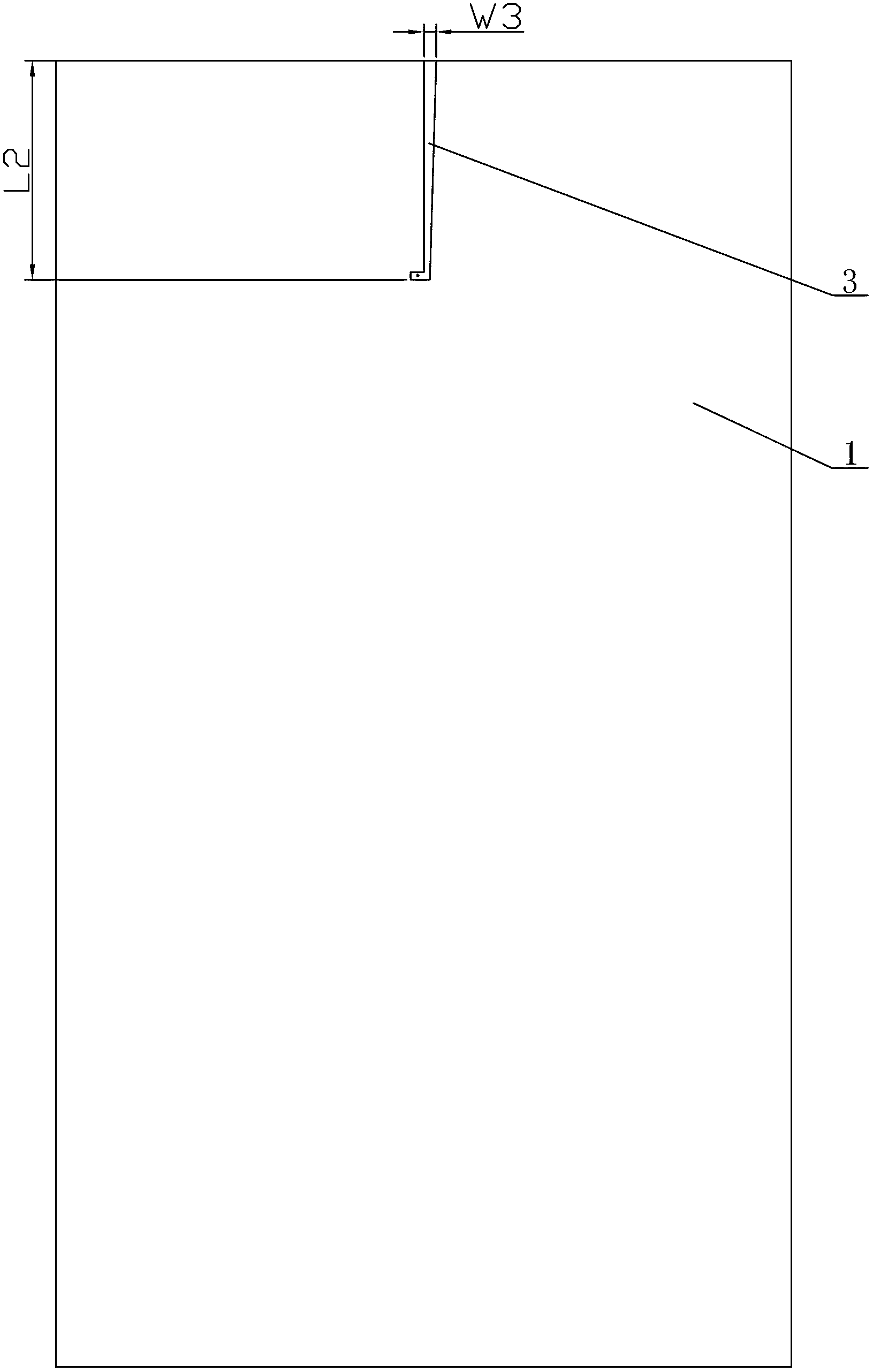

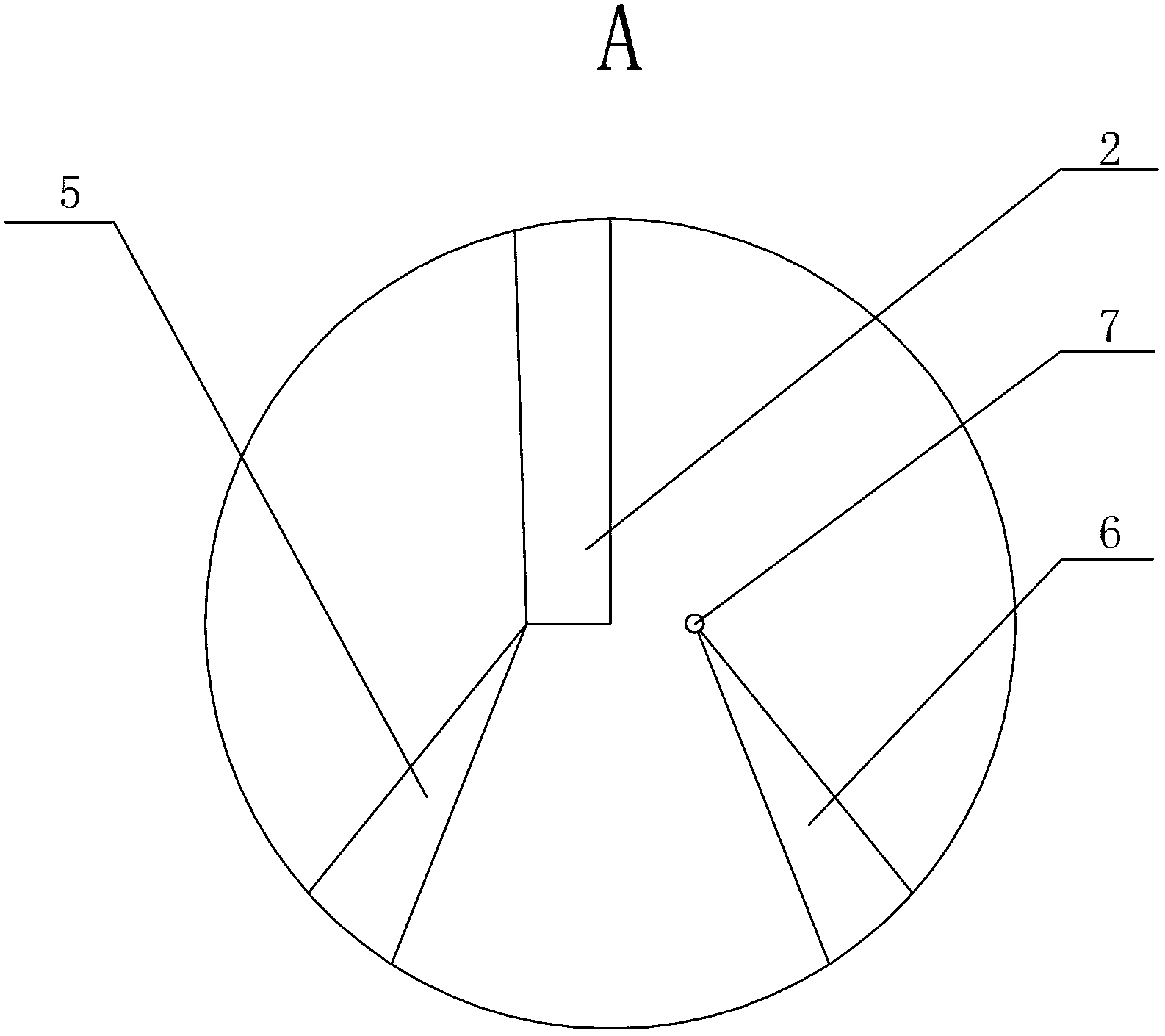

[0008] Specific implementation mode one: combine Figure 1 to Figure 3 Describe this embodiment, the printed V-shaped antenna of the balanced microstrip line feeding loaded metal disc in this embodiment includes a dielectric board 1, a first feeding structure 2, a second feeding structure 3, and a metal disc 4 , the first radiating unit 5 and the second radiating unit 6, the first feeding structure 2 is printed in the middle of the upper end of the front surface of the dielectric board 1 from top to bottom, and the upper end of the first feeding structure 2 is in contact with the dielectric board 1 The upper edge of the second feeding structure 3 is printed in the middle of the upper end of the back of the dielectric board 1 from top to bottom, and the upper end of the second feeding structure 3 is in contact with the upper edge of the dielectric board 1. The first radiation The unit 5 and the second radiating unit 6 are arranged in the middle of the front of the dielectric pl...

specific Embodiment approach 2

[0009] Specific implementation mode two: combination figure 1 Describe this embodiment, the dielectric plate 1 of the printed V-shaped antenna of the balanced microstrip line feeding load metal disc described in this embodiment is a dielectric plate 1 made of epoxy glass cloth laminated board, and the relative dielectric of the dielectric plate 1 The constant is 4.4, the length L of the dielectric board 1 is 210mm-215mm, the width W of the dielectric board 1 is 119mm-121mm, and the thickness of the dielectric board 1 is 1.5mm-2.0mm. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0010] Specific implementation mode three: combination figure 1 Describe this embodiment, the length L of the dielectric plate 1 of the printed V-shaped antenna of the balanced microstrip line feeding load metal disc described in this embodiment is 213mm, the width W of the dielectric plate 1 is 120mm, and the thickness of the dielectric plate 1 is 1.5mm.

[0011] The technical effect of this embodiment is that the feeding structure of the antenna is simple, and the medium in the radiation direction of the antenna can effectively increase the gain of the antenna, thereby compensating the loss caused by the dielectric plate.

[0012] Other components and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com