Screen

A technology of screens and screen boards, applied in screens, household appliances, applications, etc., can solve the problems of screen perishability, long production cycle, and high cost of screens, and achieve the effect of increasing the evaporation area and increasing the speed of dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

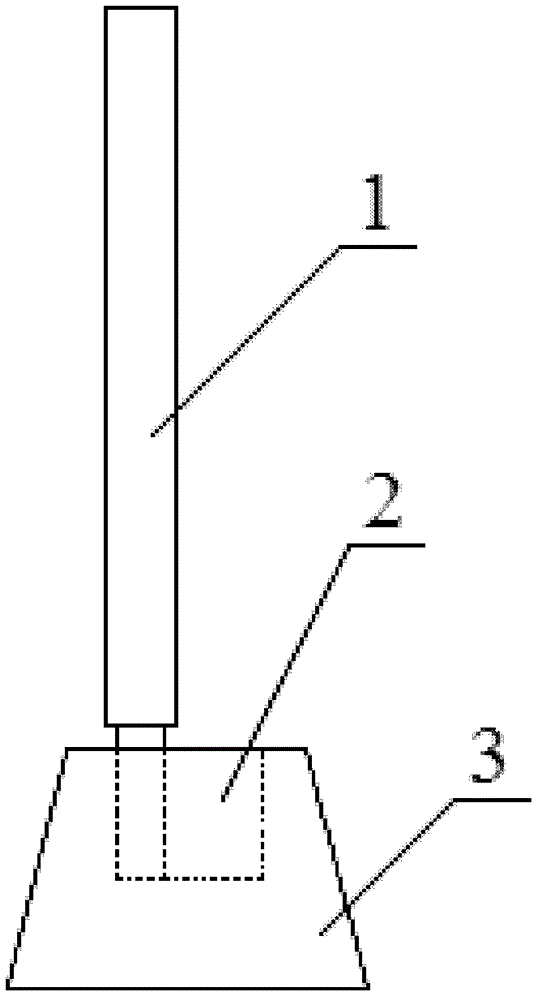

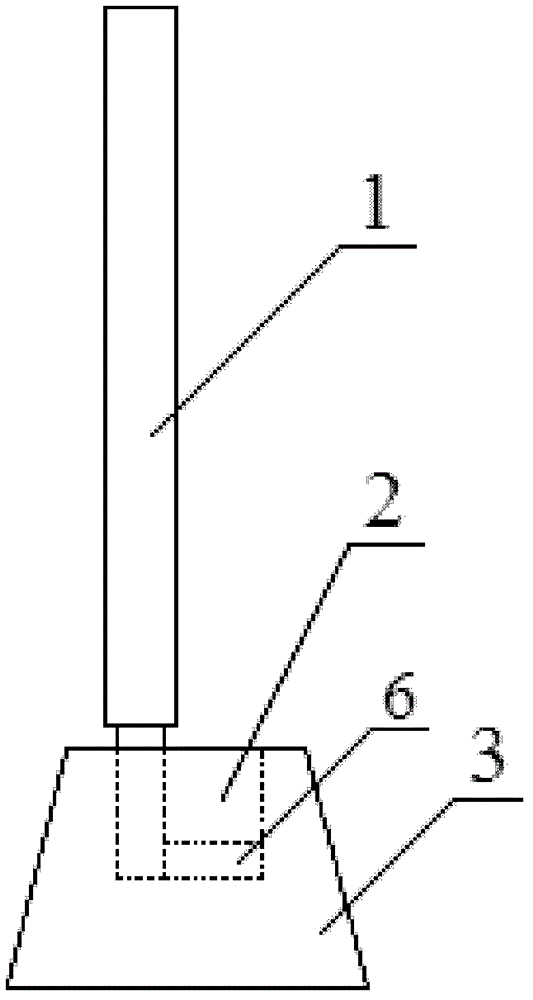

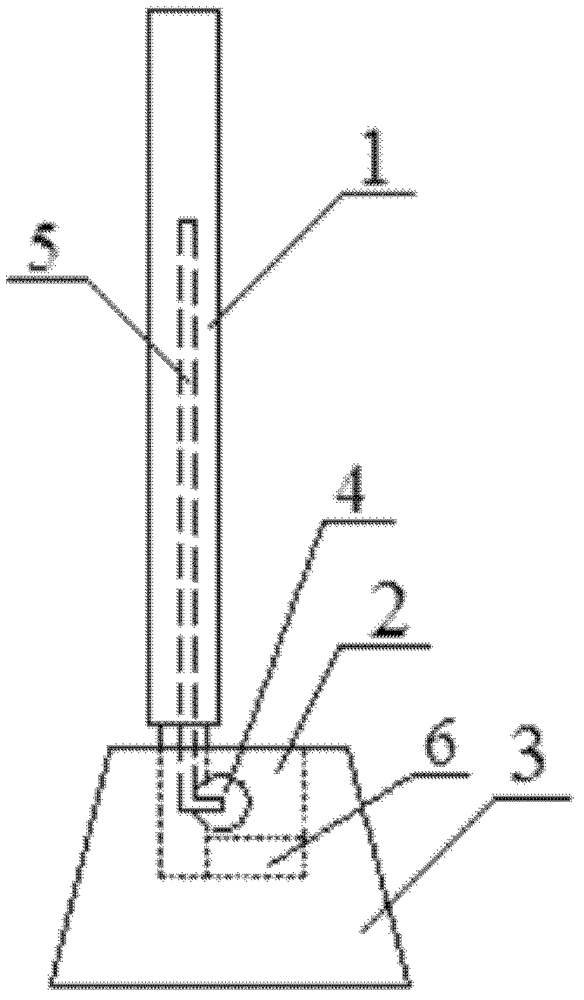

[0071] This example is used to illustrate the screen of the present invention.

[0072] Add 100 parts by weight of silica sand (particle diameter: 100-200 mesh, sphericity: 0.65) into the muffle furnace, roast at 700°C for 30 minutes, then transfer the roasted silica sand to a sand mixer, and heat it at 100r Under the stirring speed of / min, when cooling to 150°C, add 5 parts by weight of epoxy resin (the model is E51, the epoxy value is 0.48-0.54eq / 100g) and 0.2 parts by weight of CR-826 type titanium dioxide, continue Stir, and when the temperature is reduced to 100° C., add 5 parts by weight of nitrile rubber (the weight average molecular weight is about 2000, purchased from Shenzhen Peace Chemical Co., Ltd.), 1 part by weight of alumina hydrate and 0.1 part by weight of six parts by weight. methylenetetramine to obtain a sand-based composition. Use this sand base composition to combine with Figure 5 Spread a layer of material evenly on the bottom of the mold correspondi...

Embodiment 2

[0075] This example is used to illustrate the screen of the present invention.

[0076] The screen is prepared according to the method of Example 1, and the difference is that nitrile rubber is not added, so as to obtain image 3 In the screen A2 shown, the micropore diameter of the screen plate is 20-40 microns, and the porosity is 27%.

Embodiment 3

[0078] This example is used to illustrate the screen of the present invention.

[0079] The screen is prepared according to the method of Example 1, the difference is that the weight-average molecular weight of the nitrile rubber used is about 1500 (purchased from Shenzhen Peace Chemical Co., Ltd.), thereby making the screen A3, wherein the micropores of the screen plate The diameter is 20-40 microns and the porosity is 29%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com