Method and device for labelling containers with sleeve-labels

A label sleeve and labeling technology, which is applied in the field of equipment and methods for labeling containers with label sleeves, can solve problems such as interference, technical consumption, and increase the complexity of the opening unit, achieve the optimization of opening motion, and avoid excessive extension. and/or tearing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

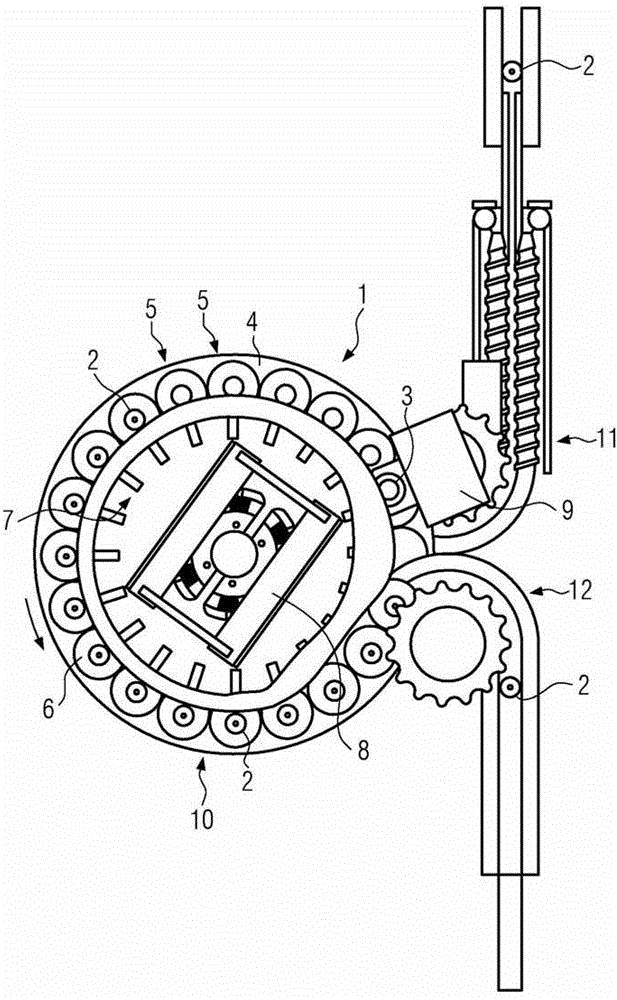

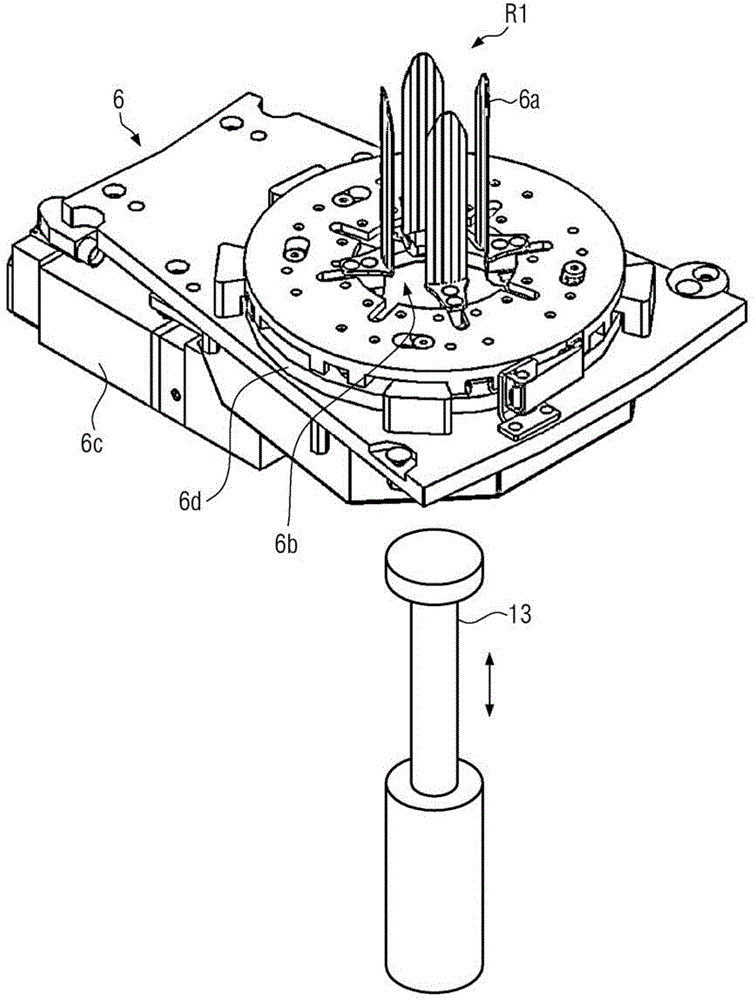

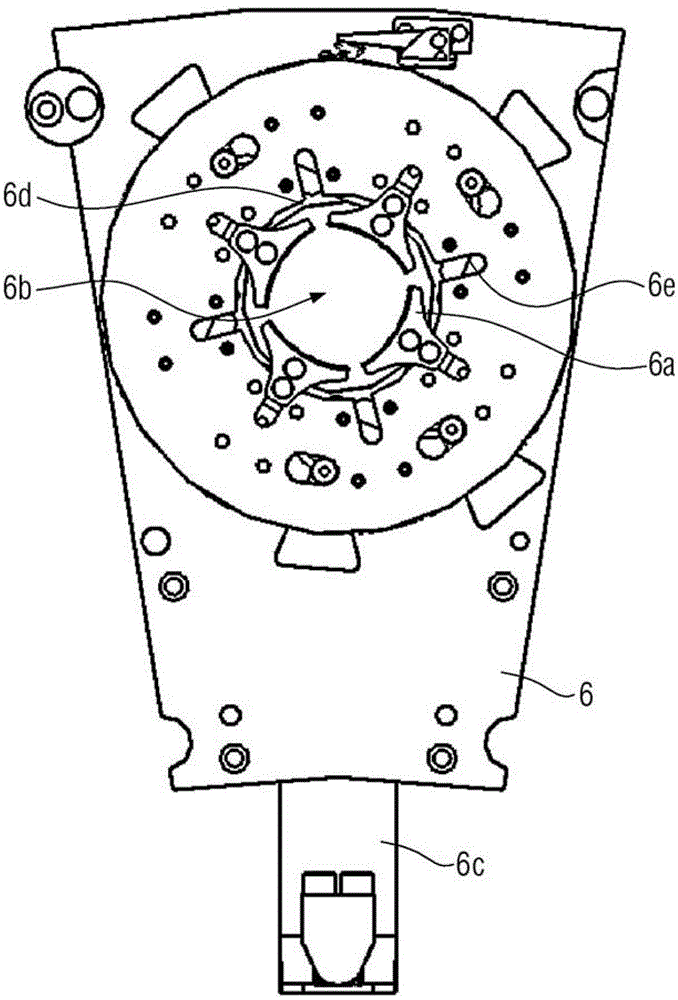

[0036] as from figure 1 As seen in , a preferred embodiment of the device 1 according to the invention for labeling containers 2 with label sleeves 3 comprises a plurality of labeling stations 5 distributed uniformly on the circumference of the labeling wheel 4, each of which An expansion unit 6 for receiving and expanding the label sleeve 3 is included. The label sleeve 3 is, for example, a shrink sleeve or a stretch sleeve. Furthermore, a removal unit 7 for grasping and lifting the labeled container 2 from the spreading unit 6, a control unit 8 for electrically controlling the labeling device 1 according to the invention, a label applicator 9, An optional shrink zone 10 for fixing the label sleeve 3 in the case of a shrink sleeve, an inlet planetary wheel 11 for conveying the containers 2 to be labeled, which may be plastic bottles, for example, and an outlet planetary wheel for removing the containers 2 round 12. Furthermore, the direction of rotation of the labeling whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com