A kind of nickel-manganese-silver-copper-chromium alloy material resistance heating device and preparation method thereof

A heating device, chromium alloy technology, applied in the direction of heating element materials, etc., can solve the problems of difficult temperature control, high power consumption, environmental pollution, etc., to prevent oxidative fracture, improve physical properties, electrical conductivity and good ductility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

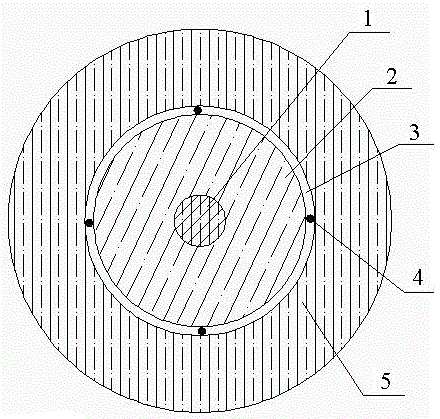

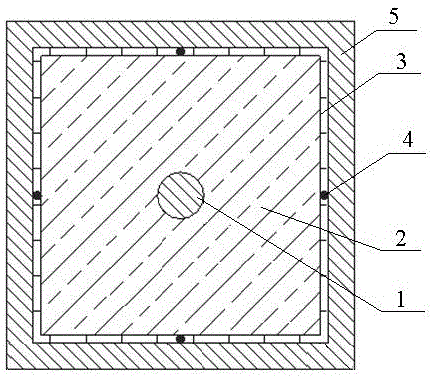

[0026] In this embodiment, a nickel-manganese-silver-copper-chromium alloy resistance heating device, the conductive core includes the following components in parts by weight: 83.42 parts of copper, 15.37 parts of nickel, 0.59 parts of chromium, 0.4 parts of manganese, and 0.22 parts of silver.

[0027] In this embodiment, the heating device is prepared as a columnar heating device, wherein the diameter of the conductive core is 0.82 mm, the thickness of the polypropylene sheath A is 2 mm, the thickness of the aluminum shielding layer is 0.15 mm, the diameter of the protective ground wire is 0.06 mm, and the polypropylene sheath B is The thickness is 0.45mm.

[0028] In this embodiment, the method for preparing a nickel-manganese-silver-copper-chromium alloy material resistance thermal effect heating device includes the following steps:

[0029] a. Copper, nickel, chromium, manganese, and silver that have been proportioned by weight are smelted and mixed by a smelting process,...

Embodiment 2

[0034] In this embodiment, a nickel-manganese-silver-copper-chromium alloy material resistance heating device, the conductive core includes the following components in parts by weight: 85 parts of copper, 18 parts of nickel, 1.5 parts of chromium, 0.6 parts of manganese, and 0.3 parts of silver.

[0035] In this embodiment, the heating device is prepared as a columnar heating device, wherein the diameter of the conductive core is 0.7 mm, the thickness of the polypropylene sheath A is 1 mm, the thickness of the aluminum shielding layer is 0.1 mm, the diameter of the protective ground wire is 0.04 mm, and the polypropylene sheath B is The thickness is 0.35mm.

[0036] The preparation method of this embodiment is the same as that of Example 1.

Embodiment 3

[0038] In this embodiment, a nickel-manganese-silver-copper-chromium alloy resistance heating device, the conductive core includes the following components in parts by weight: 84 parts of copper, 16 parts of nickel, 1.0 part of chromium, 0.5 part of manganese, and 0.15 part of silver.

[0039] In this embodiment, the heating device is prepared as a columnar heating device, wherein the diameter of the conductive core is 0.9 mm, the thickness of the polypropylene sheath A is 3 mm, the thickness of the aluminum shielding layer is 0.2 mm, the diameter of the protective ground wire is 0.08 mm, and the polypropylene sheath B is The thickness is 0.55mm.

[0040] The preparation method of this embodiment is the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com