Continuously variable transmission

A transmission device, continuously variable speed technology, applied in the transmission device, friction transmission device, transmission device control and other directions, can solve the problem of complex structure of the transmission device, and achieve the effect of ensuring work safety, reliable position measurement, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

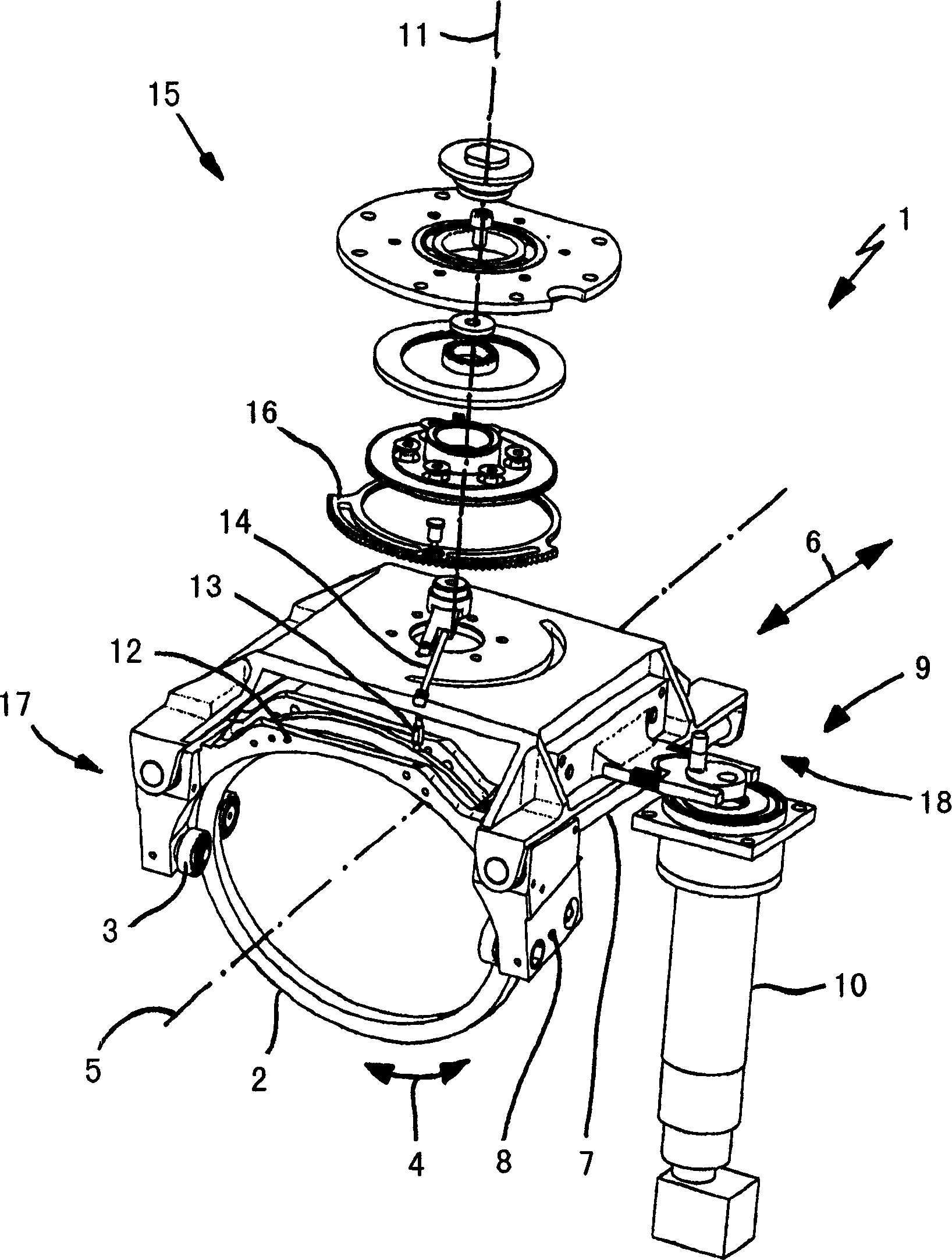

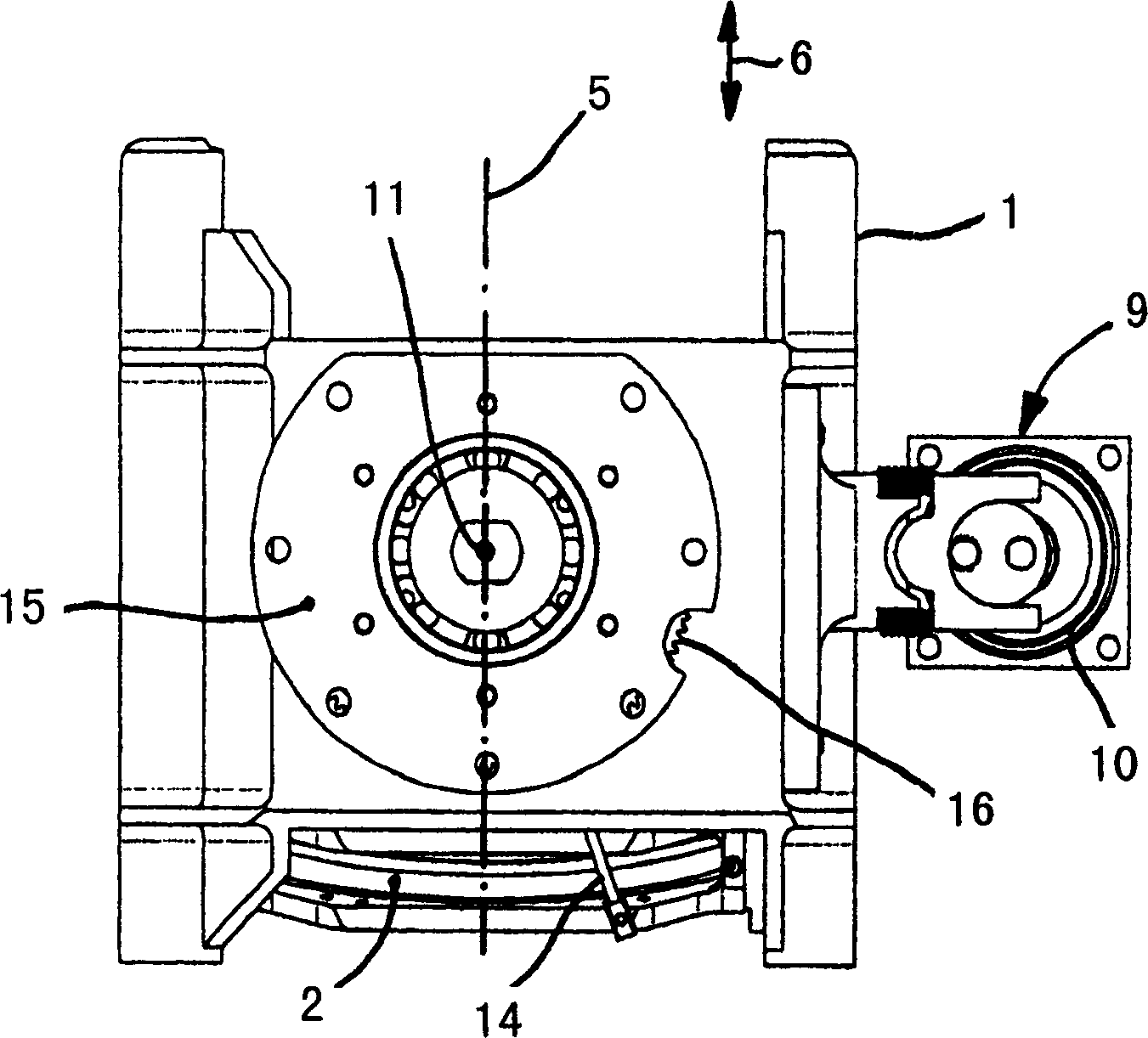

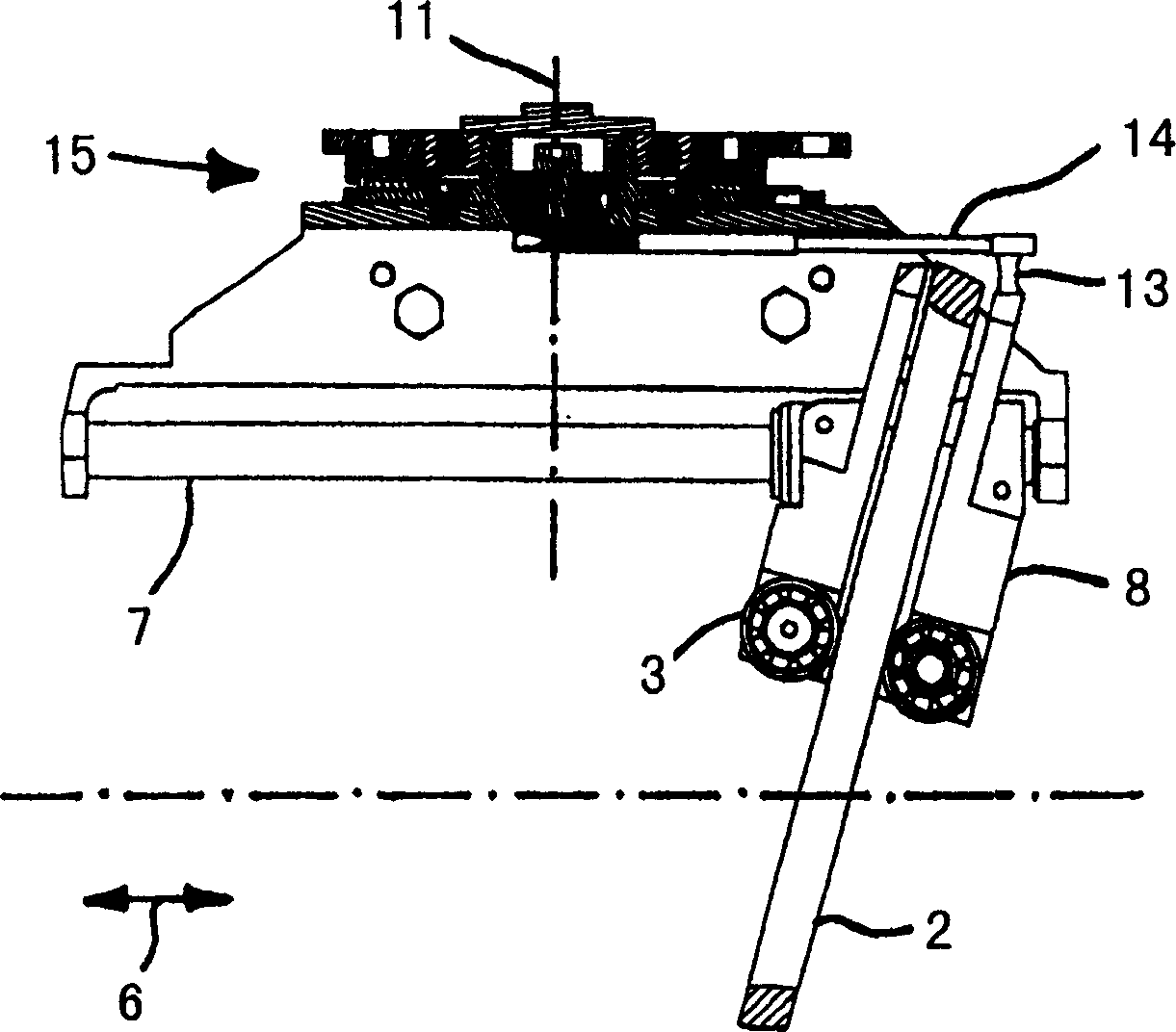

[0030] figure 1 The shown guide 1 guides a friction ring 2 . The friction ring 2 is mounted for rotation about an axis 5 in the direction of the double arrow 4 by means of guide rollers 3 (indicated here only schematically). In order to make the friction ring 2 perform a translational movement in the direction of the double arrow 6 in addition to its rotation in the direction of the double arrow 4, the guide mechanism 1 has two guide shafts 7 (only schematically marked here), on which , a guide slide 8 can translate in the direction of the double arrow 6.

[0031] The guide 1 is operatively connected in its side area 9 to an adjusting axis 10 , so that the entire guide can be rotated about a rotational axis 11 . Depending on how the guide 1 is adjusted about the axis of rotation 11 by the adjusting axis 10 , the guide carriage 8 and the friction ring 2 arranged in the guide carriage move along the axis 5 in one of the two directions of the double arrow 6 .

[0032] In the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com