a curb stone

A technology of curb stone and vertical plate, applied in the direction of side ditch/curb stone, etc., can solve the problems of loose foundation and poor drainage effect, and achieve the effect of good water permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

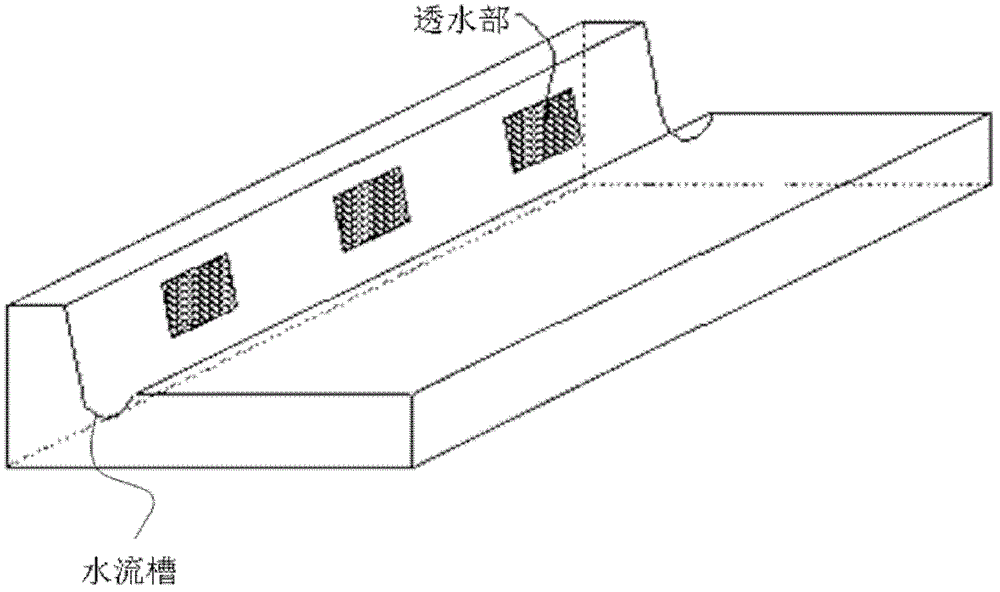

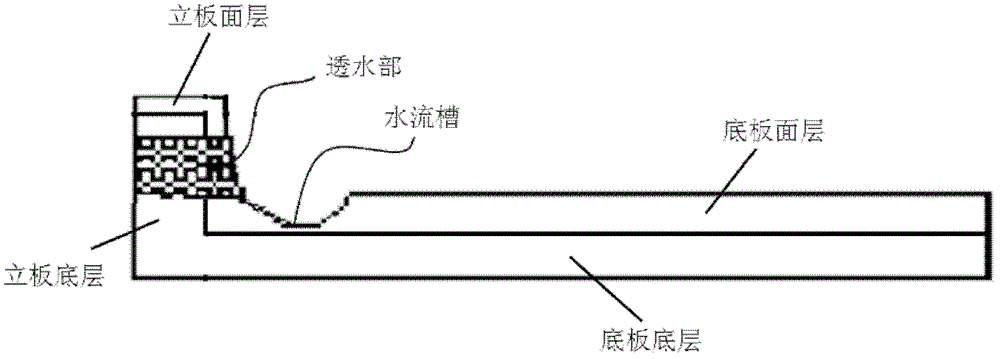

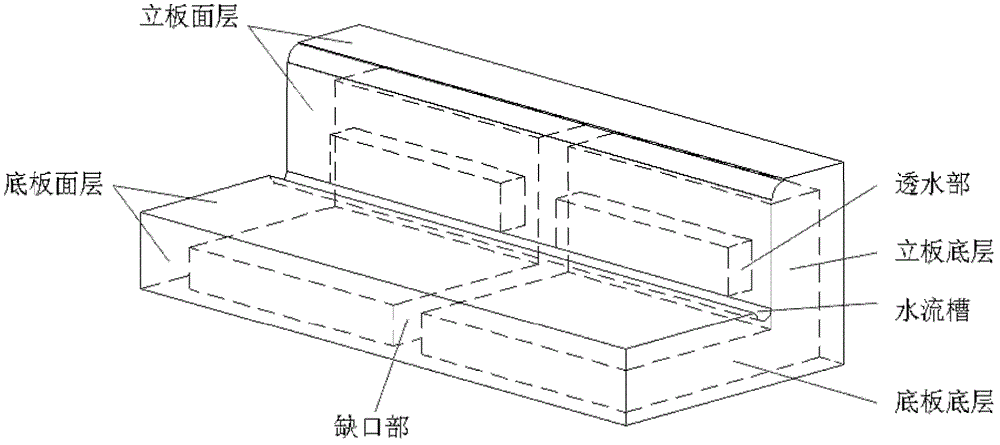

[0026] Such as figure 1 with figure 2 As shown, when there is less ponding water in the road, most of the ponding water can flow directly into the water flow tank, or penetrate into the floor surface and / or facade surface layer first, and then flow into the water flow groove. Drainage of stagnant water; when there is a lot of stagnant water in the road, the stagnant water cannot be discharged in time only through the water flow tank, and the road stagnant water may overflow the water flow groove; therefore, preferably, the bottom position of the permeable part is not higher than the top surface of the base plate. When the accumulated water in the water flow groove overflows the water flow groove, it can also be smoothly discharged from the water permeable part. According to the present invention, as long as the pore diameters of the porous structure of the permeable part are ensured to be larger than the pore diameters of the porous structure of the bottom layer of the vert...

Embodiment 1

[0043] This embodiment is used to illustrate the curbstone provided by the present invention and its preparation.

[0044] 1000g perlite (average particle diameter is 3.5 millimeters), 100g cement and 100g water are mixed uniformly, obtain the mixture that forms base plate bottom layer and vertical plate bottom layer; In the steel curb bottom layer mold with holes, solidify at 40°C for 500min to obtain the bottom layer of the bottom plate and the bottom layer of the vertical plate with an integrated structure. The thickness of the bottom layer of the bottom plate and the bottom layer of the vertical plate is 10cm, and the diameter of the hole is 0.5mm. The porosity was both 15%.

[0045] Mix 1000g of silica sand (average particle diameter of 0.05mm), 100g of water-based epoxy resin (Bluestar New Material Wuxi resin, E-44) and 5g of diethylenetriamine to obtain a mixture that forms the surface layer of the bottom plate and the surface layer of the vertical plate ; Lay the mixt...

Embodiment 2

[0049] This embodiment is used to illustrate the curbstone provided by the present invention and its preparation.

[0050] Mix 600g of ceramsite (average particle diameter is 7 mm), 12g of silicate and 10g of water to obtain a mixture that forms the bottom layer of the bottom plate and the bottom layer of the vertical plate; lay the mixture on the surfaces with water flow grooves and through both sides of the vertical plate In the through-hole steel curb bottom layer mold, solidify at 40°C for 500min to obtain the bottom layer of the bottom plate and the bottom layer of the vertical plate with an integrated structure. The thickness of the bottom layer of the bottom plate and the bottom layer of the vertical plate is 9cm, and the hole diameter is 5 mm and porosity are both 30%.

[0051] 600g silica sand (average particle diameter is 3mm), 12g waterborne polyurethane resin (Liaoning Nikkei Consulting Co., Ltd., F417505) and 0.24g toluene diisocyanate are mixed homogeneously, obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com