centrifugal fan

A technology of centrifugal blades and blades, which is applied to parts of pumping devices for elastic fluids, non-variable pumps, machines/engines, etc., which can solve the problem of not many centrifugal blades and achieve good static pressure values , increase the air intake area, and eliminate the effect of noise peaks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

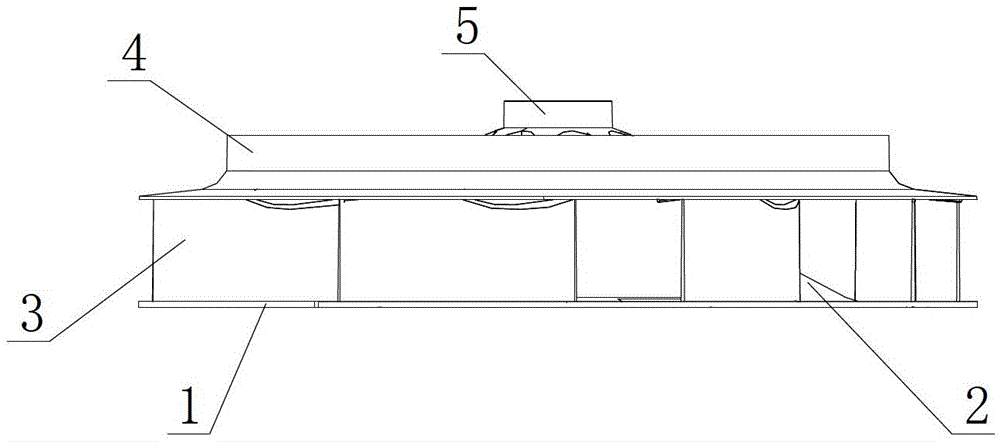

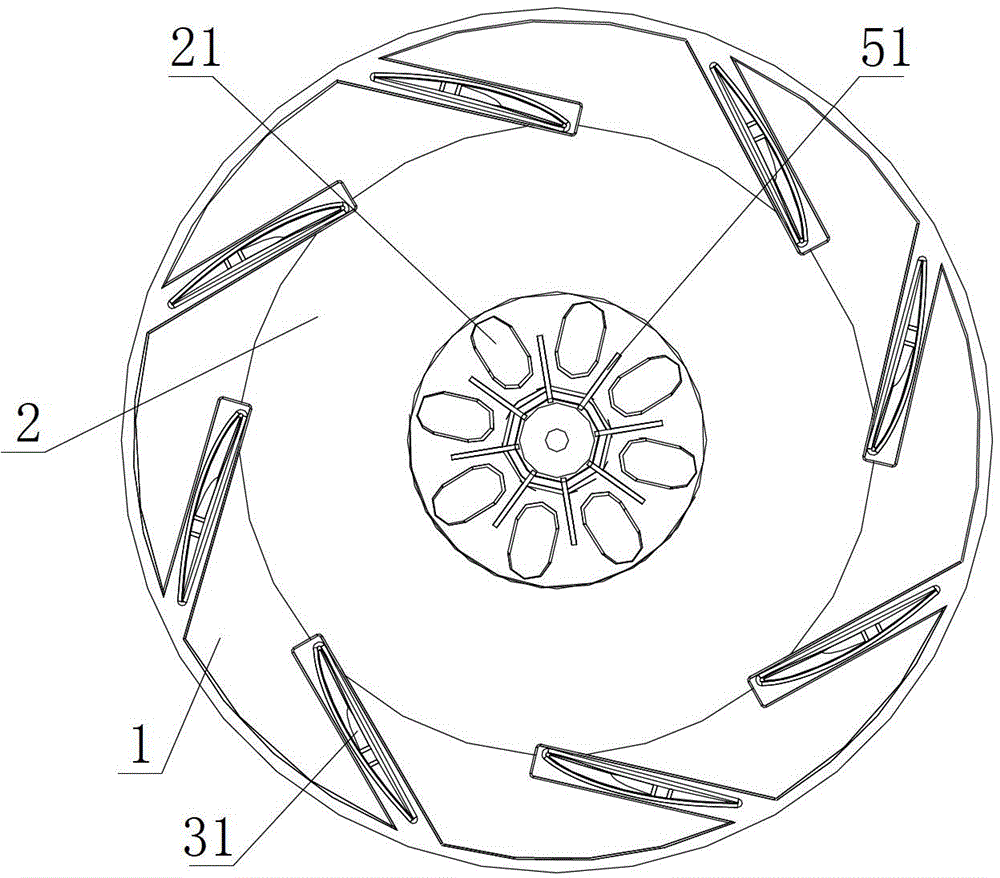

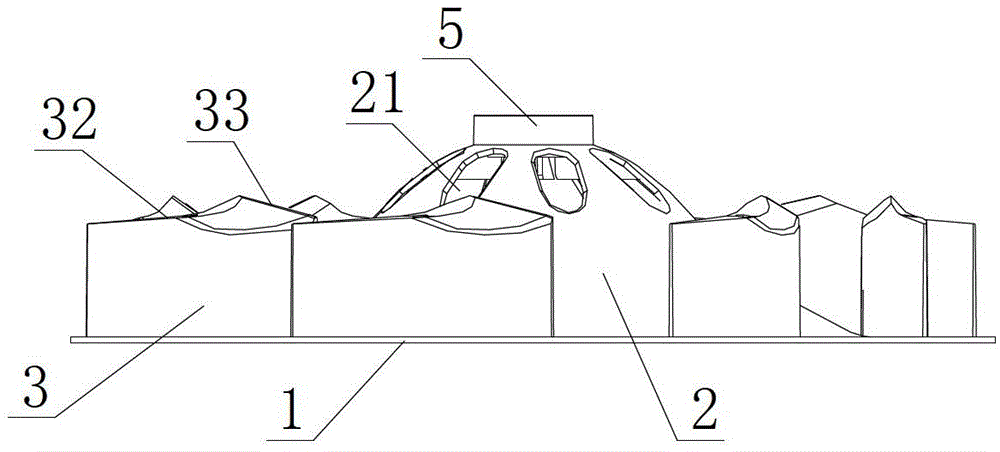

[0016] Combine below figure 1 , figure 2 , image 3 with Figure 4 Make a detailed explanation to the specific embodiment of the invention.

[0017] Such as figure 1 , figure 2 , image 3 with Figure 4 The centrifugal fan blade shown mainly includes an annular leaf base plate 1, a hub 2, blades 3 and a guide ring 4, the blades 3 are 8 pieces, and the 8 blades 3 are vertically arranged on the annular leaf base plate 1 and the guide ring 4, the hub 2 is integrated with the inner side of the annular leaf base plate 1, the hub 2 is concentric with the annular leaf base plate 1, and the center of the top of the hub 2 is provided with a cylindrical plastic shaft hole sleeve 5 connected with it. A material-saving cavity 31 is set inside the blade 3, and eight cooling holes 21 are arranged on the hub 2, and the eight cooling holes 21 are arranged at regular intervals, and each cooling hole 21 is located from the outer air outlet end of the blade 3 to the ring-shaped blade. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com