Thin-type fan

A thin fan and fan frame technology, which is used in the components of pumping devices for elastic fluids, non-variable-capacity pumps, machines/engines, etc., can solve the problem of low heat dissipation efficiency, overall height reduction, bearing oil storage capacity Reduce and other problems to achieve the best heat dissipation performance, enhance stability, and ensure the effect of oil storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

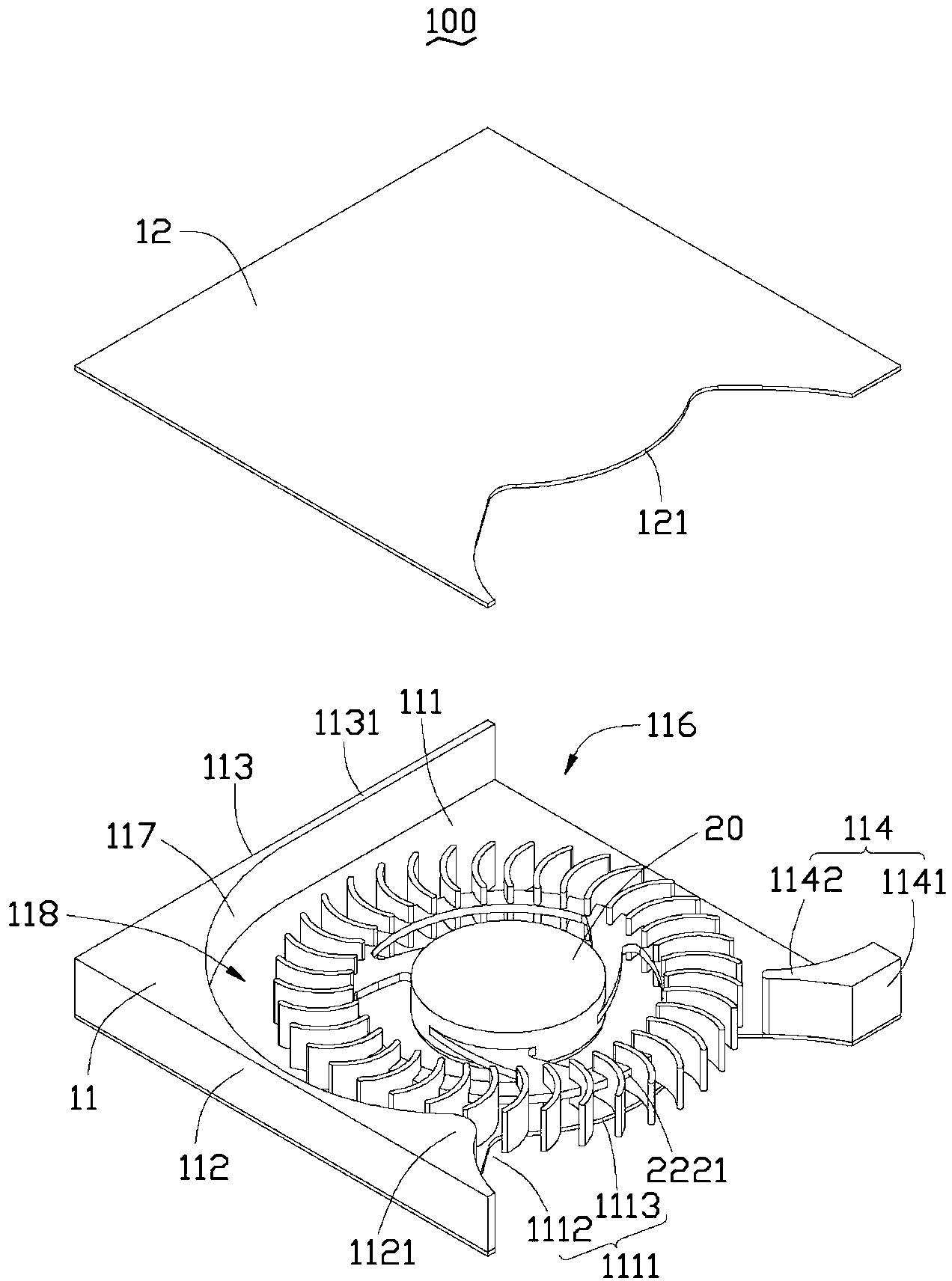

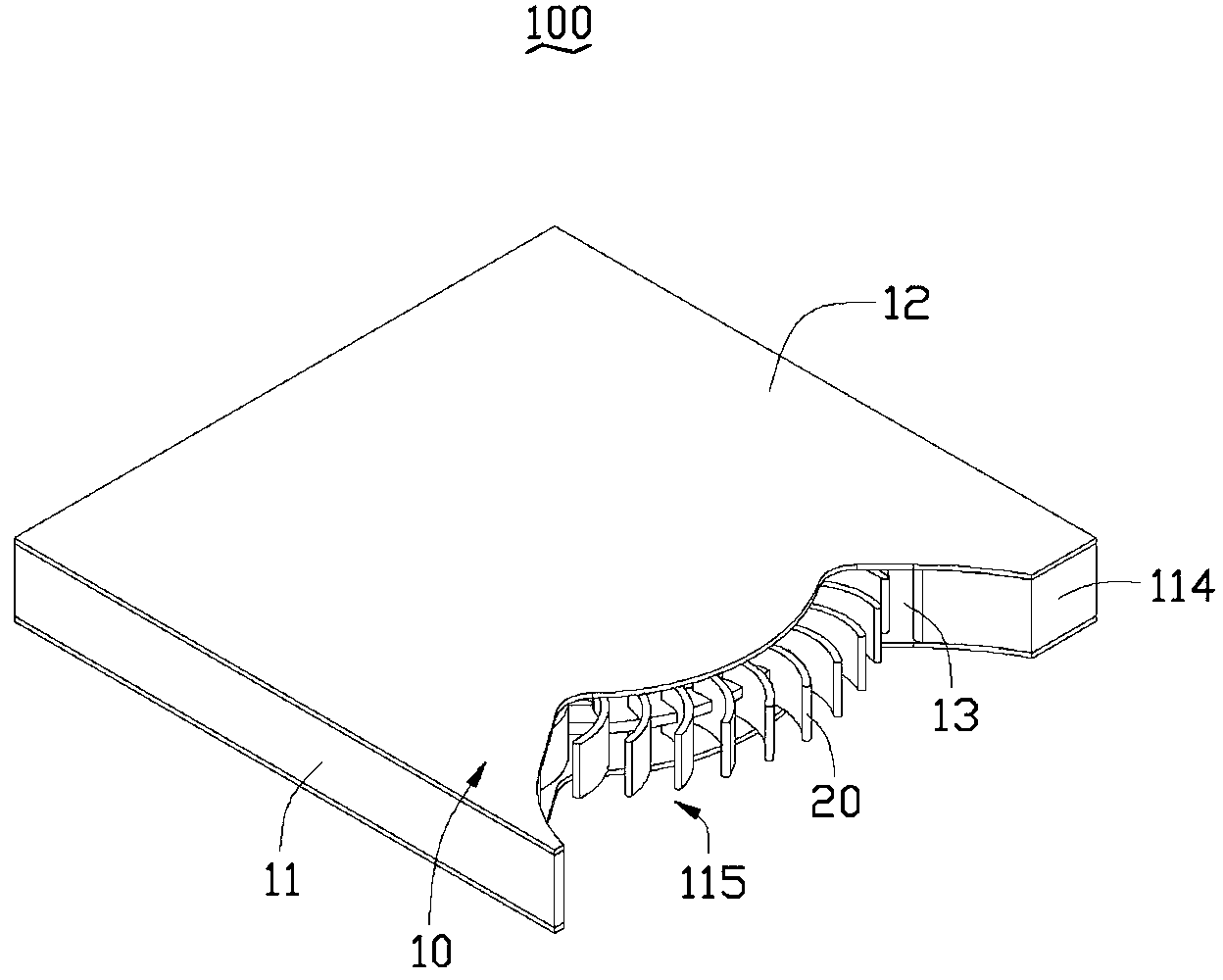

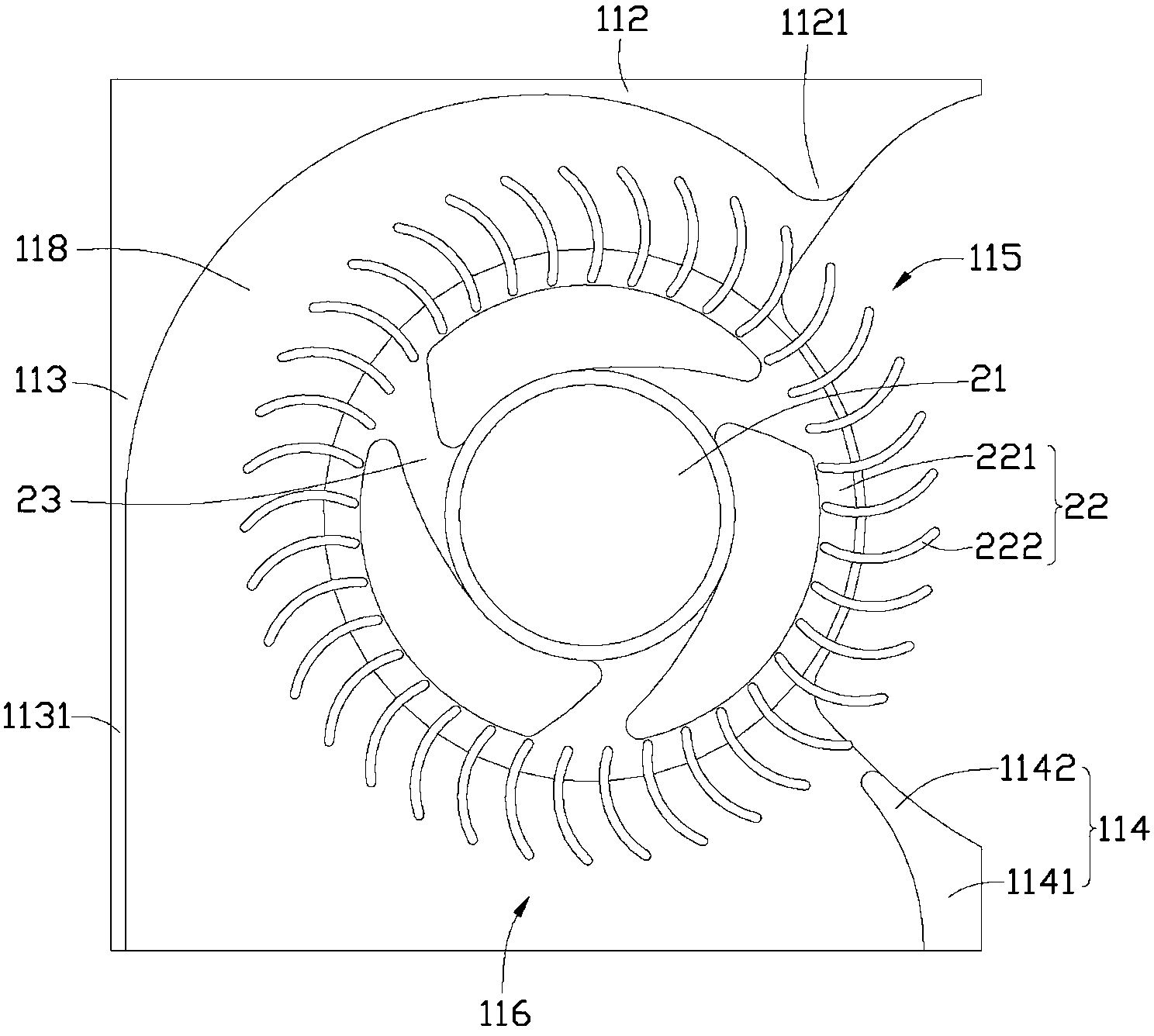

[0018] see Figure 1 to Figure 3 , is a thin fan 100 according to the first embodiment of the present invention, which includes a fan frame 10 and an impeller 20 accommodated in the fan frame 10 . The thin fan 100 can be clamped and fixed on a related electronic device (not shown), so as to assist the electronic device to dissipate heat.

[0019] Specifically, see figure 1 , the fan frame 10 includes a fan base 11 and an upper cover 12 located on the fan base 11 , the fan base 11 and the upper cover 12 enclose a receiving space 13 for accommodating the impeller 20 . The fan base 11 includes a bottom plate 111 , a first side wall 112 extending upward from the edge of the bottom plate 111 , a second side wall 113 , and a third side wall 114 opposite to the second side wall 113 . The bottom plate 111 is in the shape of a square flat plate, and its edge adjacent to the third side wall 114 is inwardly recessed to form a first recess 1111. The first recess 1111 is roughly in the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com