Organic light emitting device and method for manufacturing the same

A technology of organic light-emitting devices and light-emitting layers, which is applied in the fields of organic semiconductor devices, semiconductor/solid-state device manufacturing, and electric solid-state devices, and can solve problems such as difficult multiple layers, damage, and inapplicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Specific embodiments of the invention will now be described in detail, examples of preferred embodiments of the invention are illustrated in the accompanying drawings. Wherever possible, the same reference numbers will be used throughout the drawings to refer to the same or like components.

[0038] Hereinafter, an organic light emitting device and a method of manufacturing the same according to the present invention will be described in detail with reference to the accompanying drawings.

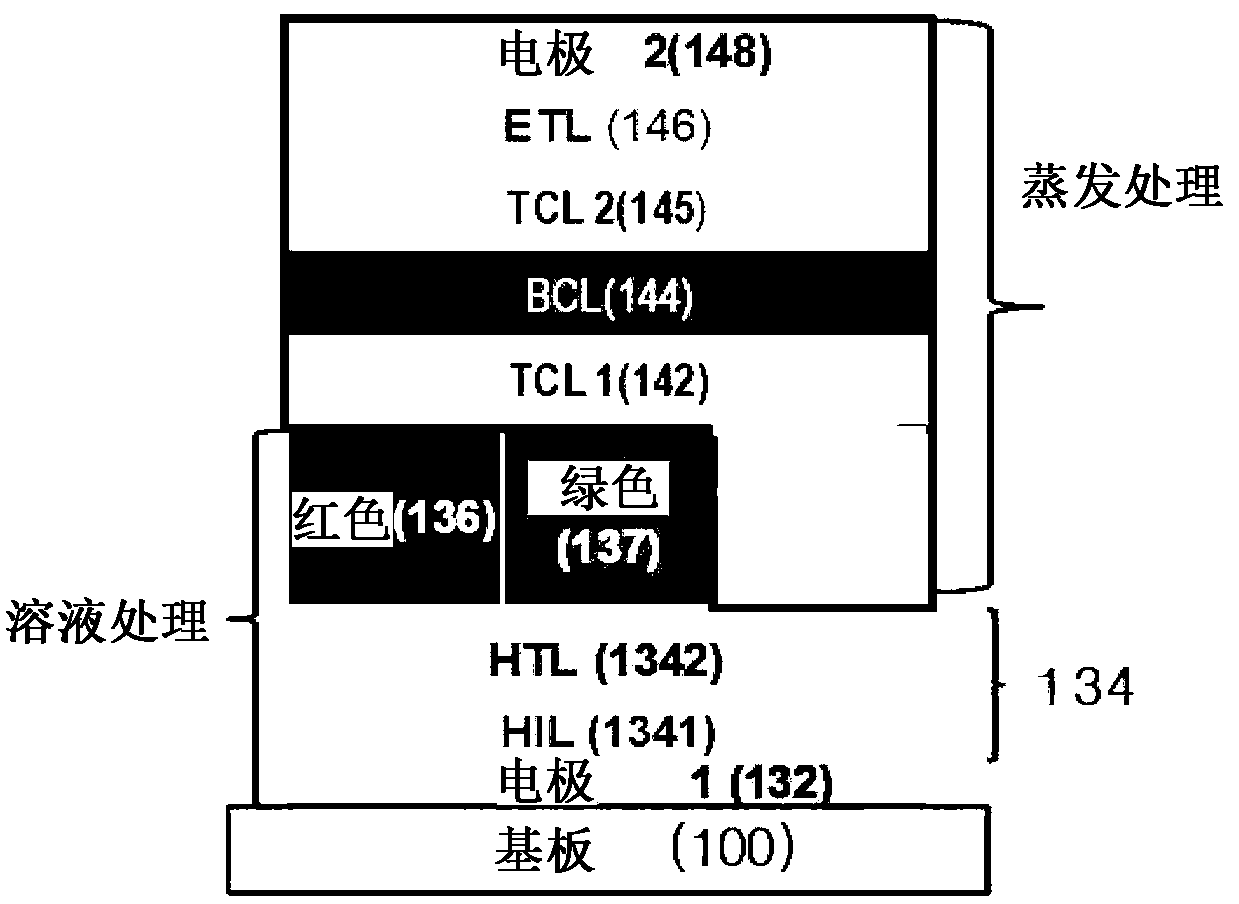

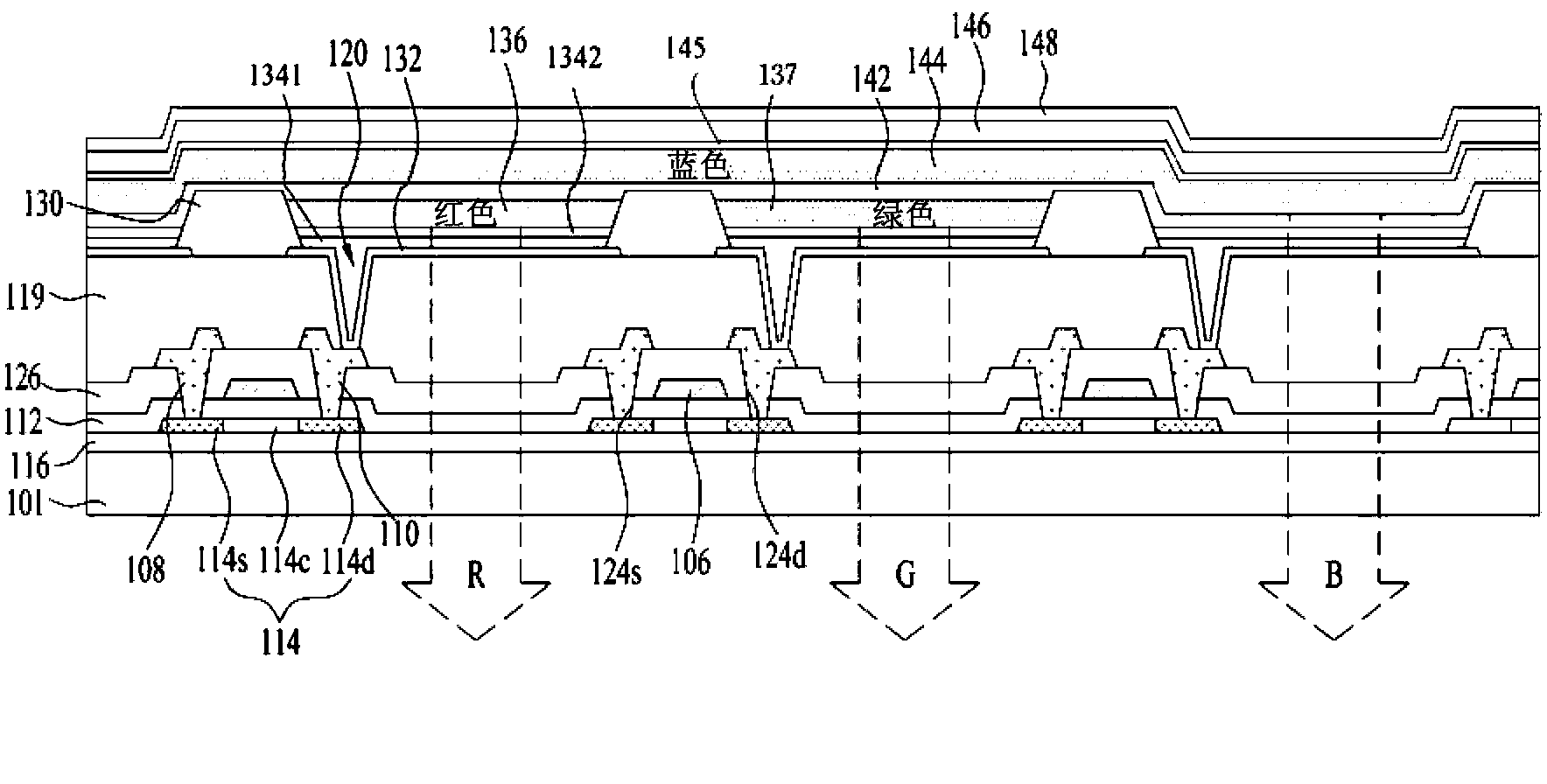

[0039] figure 1 is a sectional view illustrating an organic light emitting device according to the present invention.

[0040] Such as figure 1As shown, the organic light emitting device includes a TFT substrate 100 divided into and defined by first to third pixels, a first electrode 132 arranged on the TFT substrate, facing the first electrode 132 and connected to the first electrode 132. A second electrode 148 separated by an electrode 132, a first light emitting layer 136 arran...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap