Granary unloading mechanism of harvester

A technology for harvesters and granaries, which is applied to harvesters, agricultural machinery and implements, cutters, etc., can solve problems such as inaccurate grain output, large sloshing of the auger cavity, and short service life, so as to achieve accurate grain output and long service life Long, small shaking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

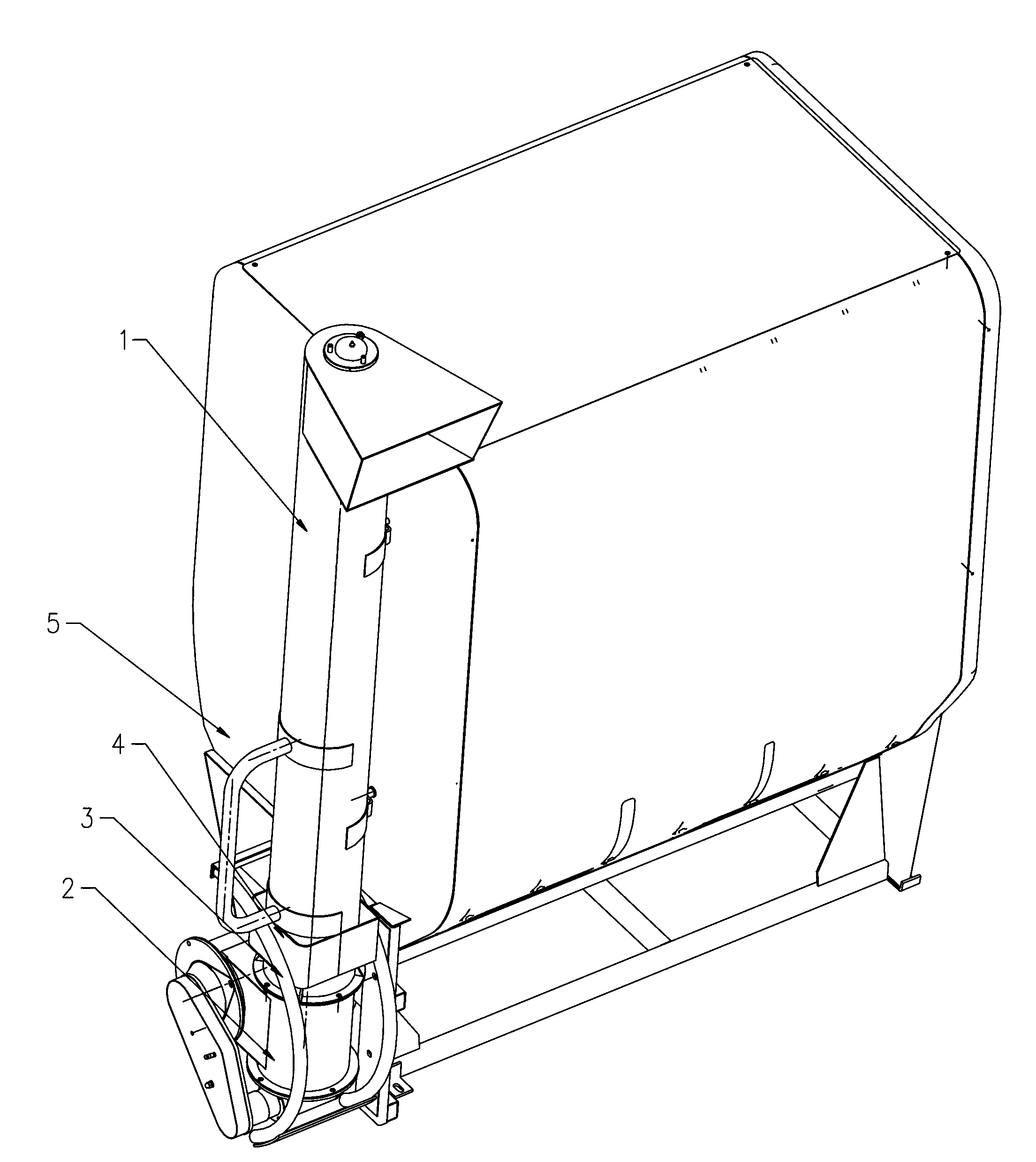

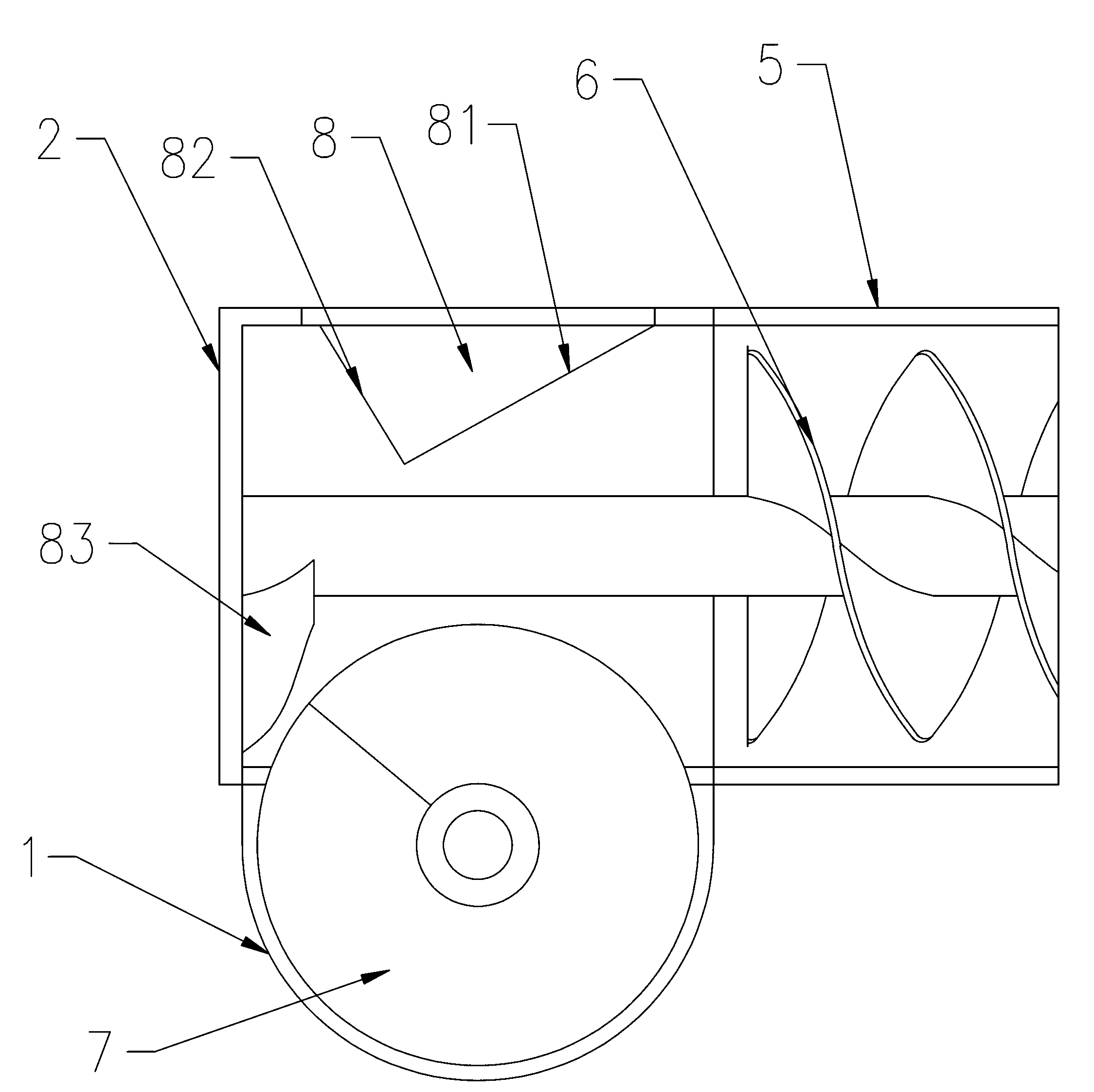

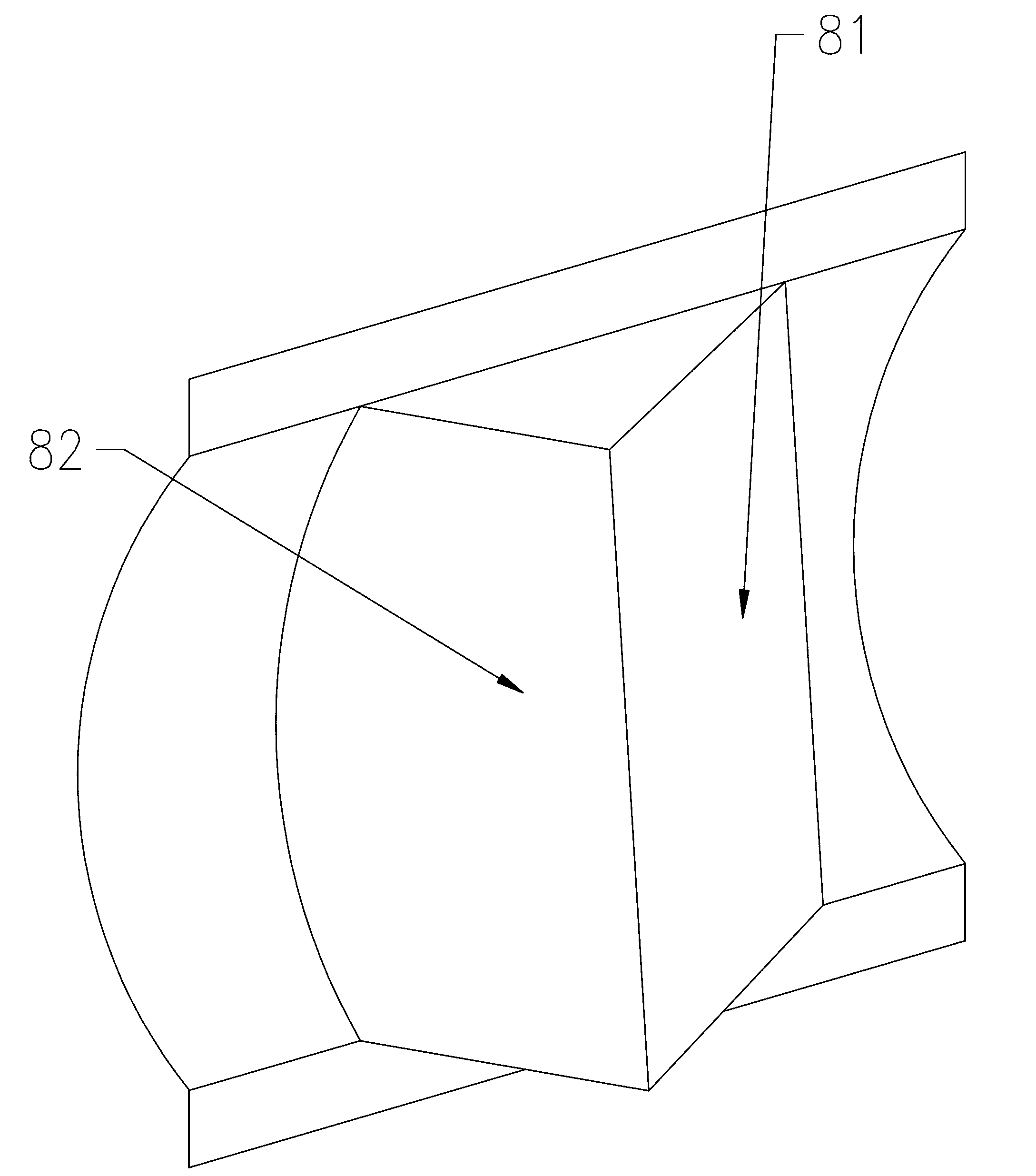

[0021] Such as figure 1 , figure 2 , image 3 As shown, the present invention is a granary unloading mechanism of a harvester, comprising an auger, the lower part of the granary is a grain unloading cavity 5, and a horizontal auger 6 is arranged in the unloading cavity 5, and the end of the horizontal auger 6 passes through Through the grain unloading port on one side of the granary, there is a transition chamber 2 connected to it on the outside of the grain unloading port and connected to the granary in rotation. The transition chamber 2 is connected to a longitudinal auger chamber 1, and the longitudinal auger A longitudinal auger 7 is arranged in the cavity 1, and the upper end of the longitudinal auger cavity 1 is a grain outlet, and the side of the granary is provided with an anti-swing frame, which includes two symmetrically arranged arc rails 3, the arc rails The center of the rail 3 falls on the center of the rotating shaft of the transition chamber, and the longitu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com