Whistle candy gluing machine

A technology of gluing machine and whistle candy, which is applied in confectionary, confectionary industry, food science, etc., can solve the problems of irregular candy pieces, low product qualification rate, poor bonding quality, etc., and achieve fast bonding speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

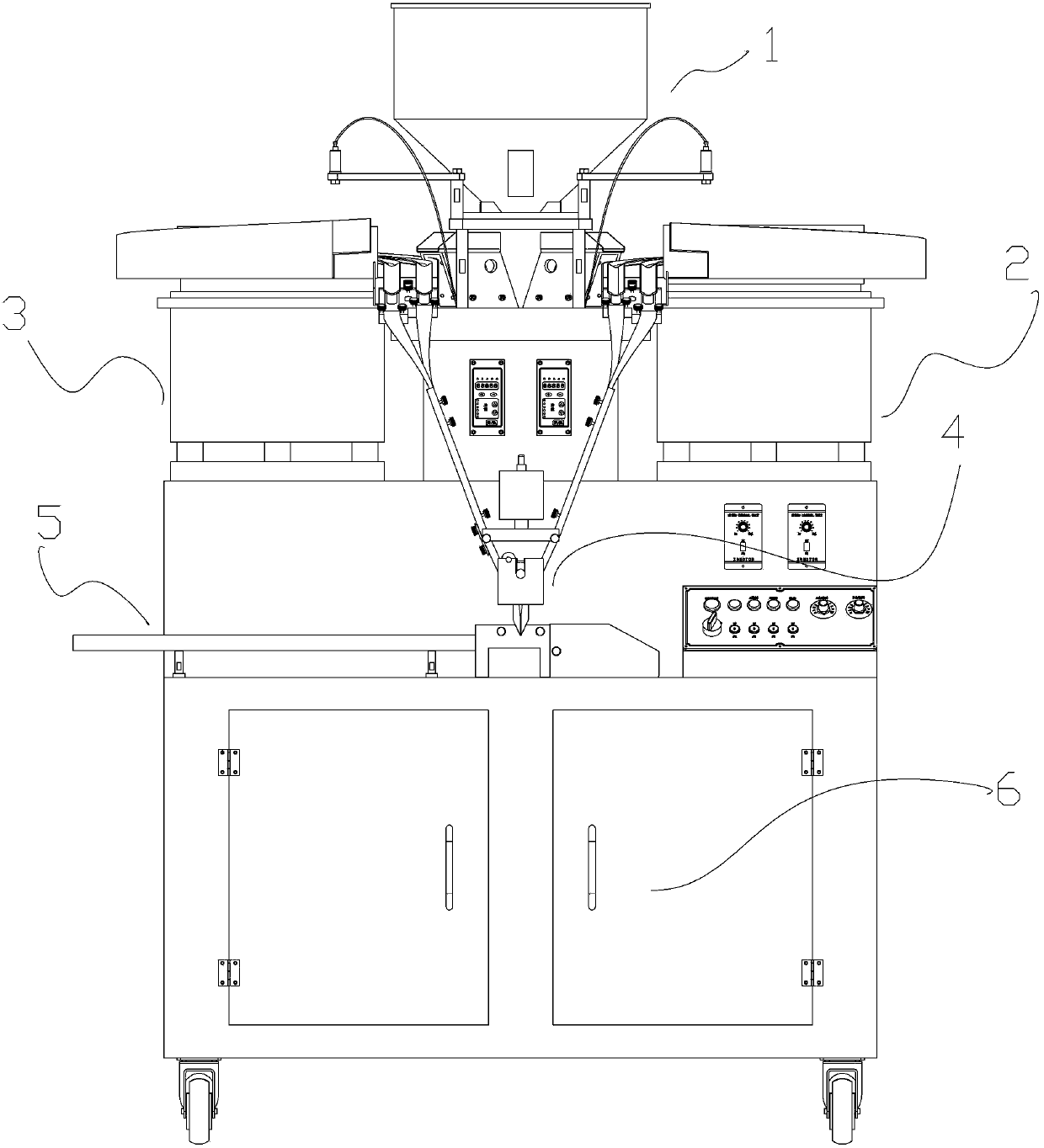

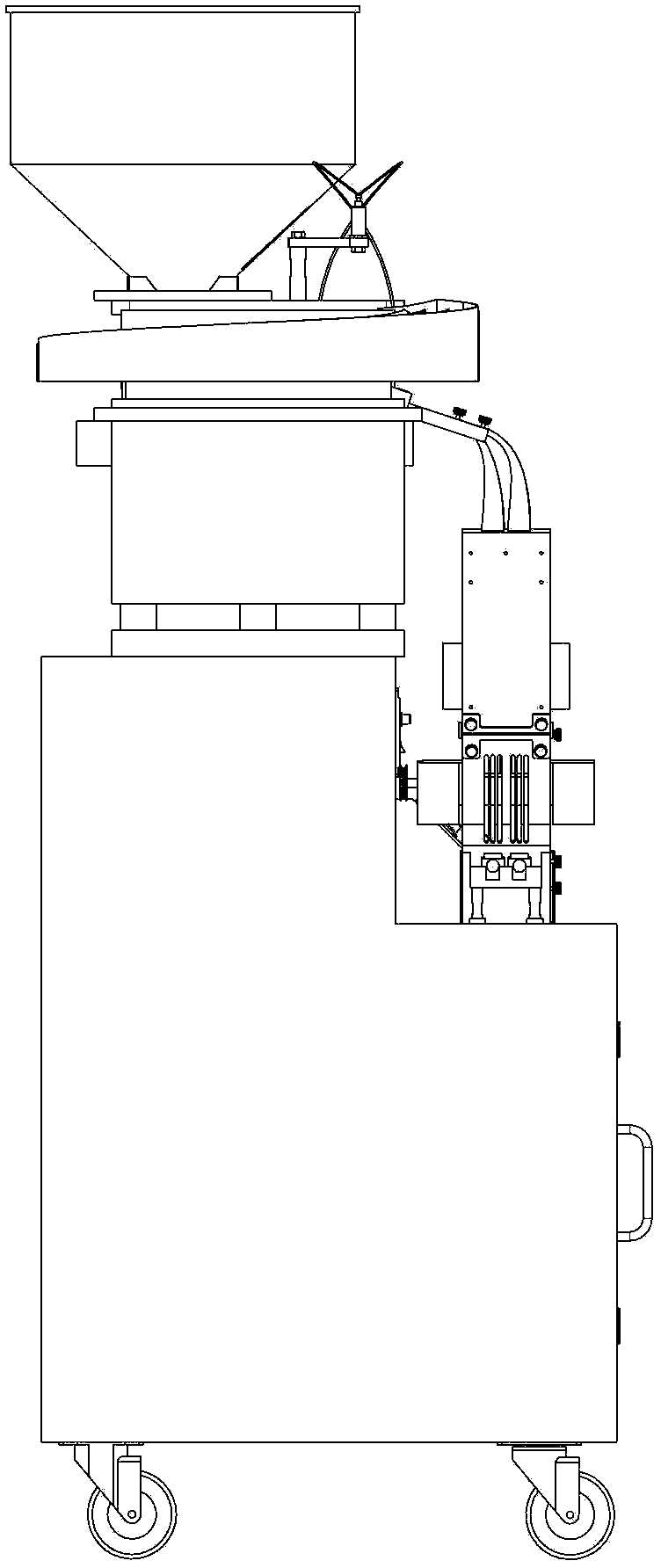

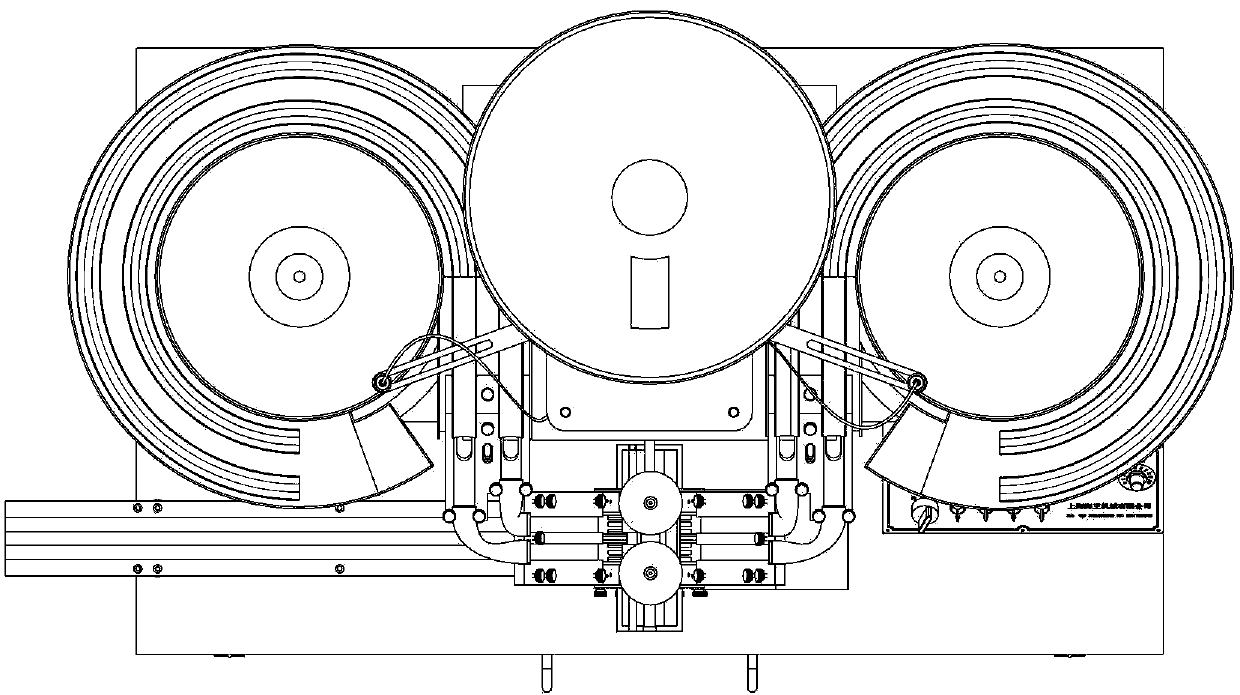

[0044] like Figures 1 to 3 as shown, figure 1 For the front view of the whistle sugar gluer, figure 2 For the left view of the whistle sugar gluer, image 3 A top view of the whistle sugar gluer.

[0045] A whistle candy bonding machine, comprising a feeding device 1, a first material handling device 2, a second material handling device 3, a coating device 4, a discharging device 5 and a control device 6, the feeding device 1, the first material handling device 2 and the second material handling device 3 are located on the boss on the control device 6, the feeding device 1 is located in the middle of the first material handling device 2 and the second material handling device 3, the first material handling device 2 and the second material handling device The device 3 is connected with the coating device 4, and the lower ends of the first material arrangement device 2 and the second material arrangement device 3 are connected with the discharge device 5, and the discharge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com