Assembling-type ink-jet printer ink box

An inkjet printer and assembled technology, applied in the field of assembled inkjet printer cartridges, can solve the problems of difficult compressing and accommodating operations, residual ink typing quality, scattered accommodating states, etc., reducing the number of parts, reducing production costs, and reducing The effect of production engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The invention will be further described below in conjunction with the accompanying drawings.

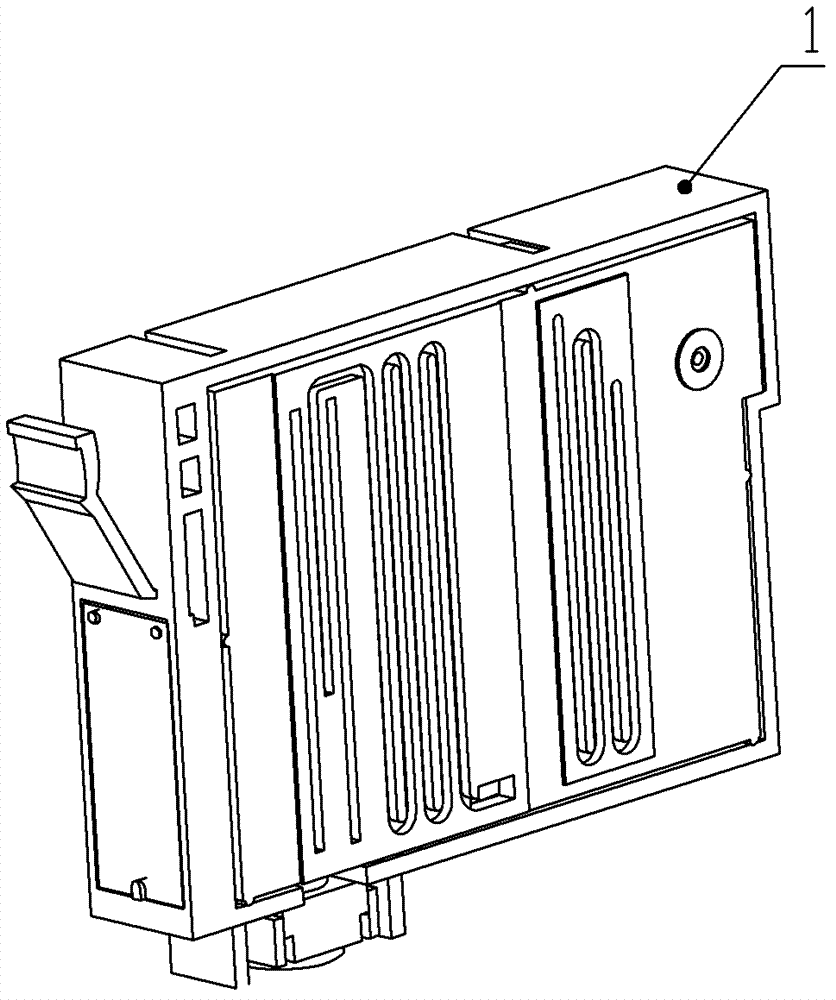

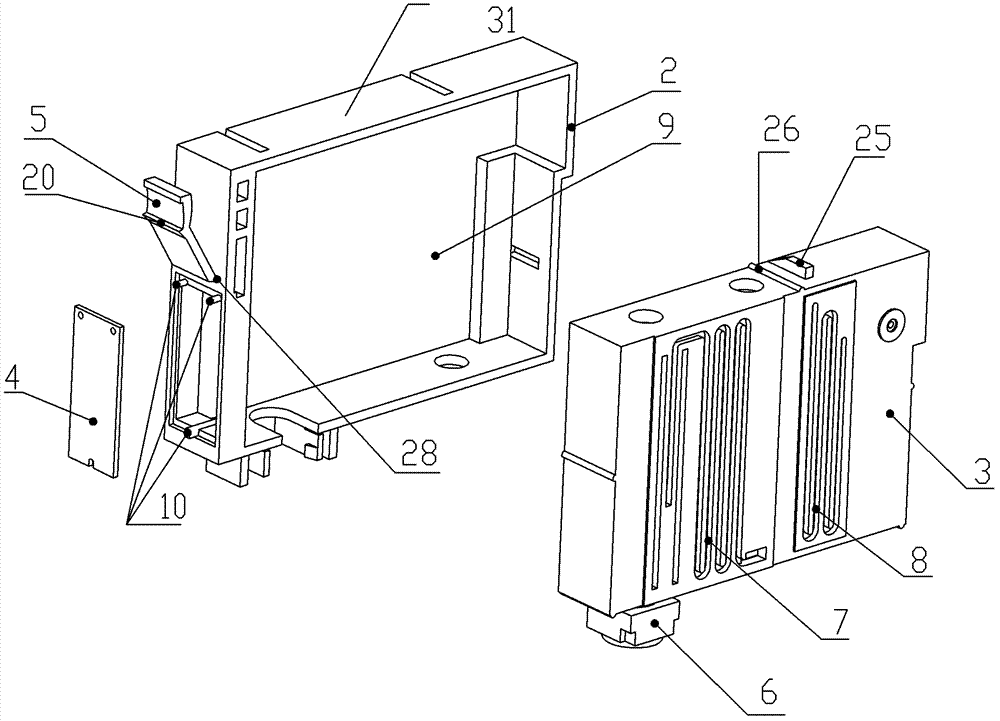

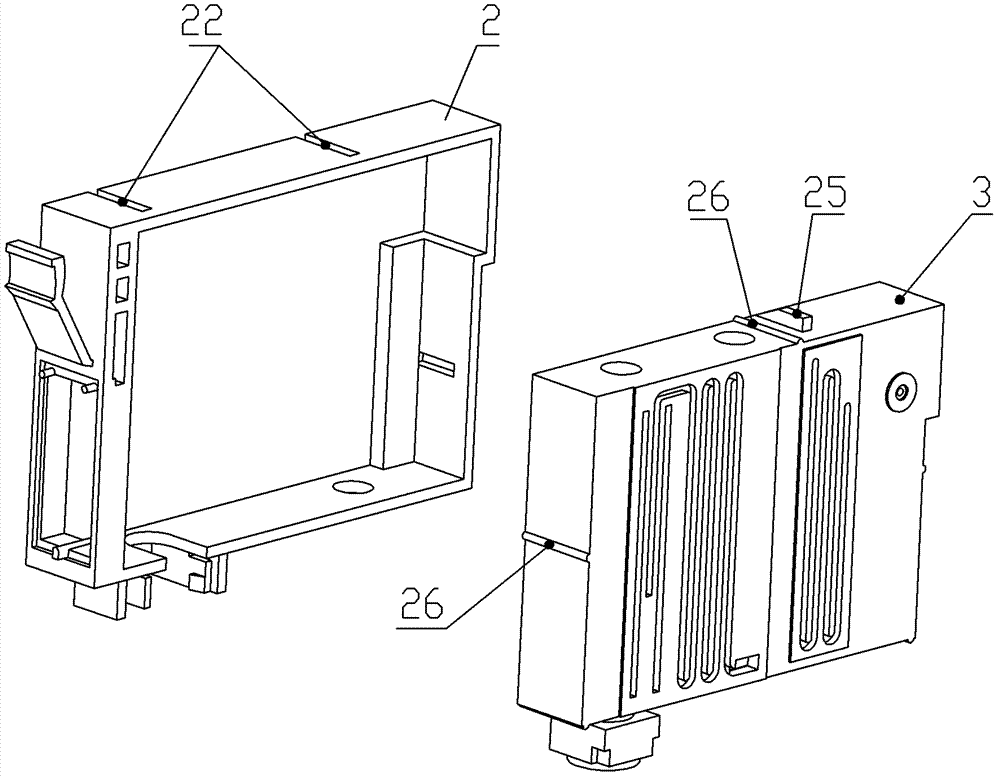

[0045] As shown in Figures 1-9, this assembled inkjet printer ink cartridge includes a shell 2 and an ink cartridge 3 that are independently formed and cooperate with each other. The shell is provided with an opening 9 for accommodating the ink cartridge. The ink The box is provided with an ink container for storing ink, an ink supply section 6 for ensuring continuous supply of ink, an ink supply route 7 for ensuring stable ink supply, and a serpentine groove 8 for injecting air; the ink box 3 It includes an ink storage chamber 41 formed by a rectangular space 31 and a hot-melt film 42, and a hole 33 communicating with the ink storage chamber. A negative pressure generating part 34 for ink supply is arranged in the rectangular space. The negative pressure generating part 34 includes an ink storage space 70 and a sponge foam 72 arranged at the bottom thereof. The ink box is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com