Motor vehicle tire inflation aids

An auxiliary device and motor vehicle technology, which is applied in vehicle maintenance, transportation and packaging, vehicle maintenance/repair, etc., can solve problems such as inability to complete inflation at one time, prolong maintenance time, and hurt maintenance workers, so as to shorten inflation time and reduce Effects of gas leakage and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

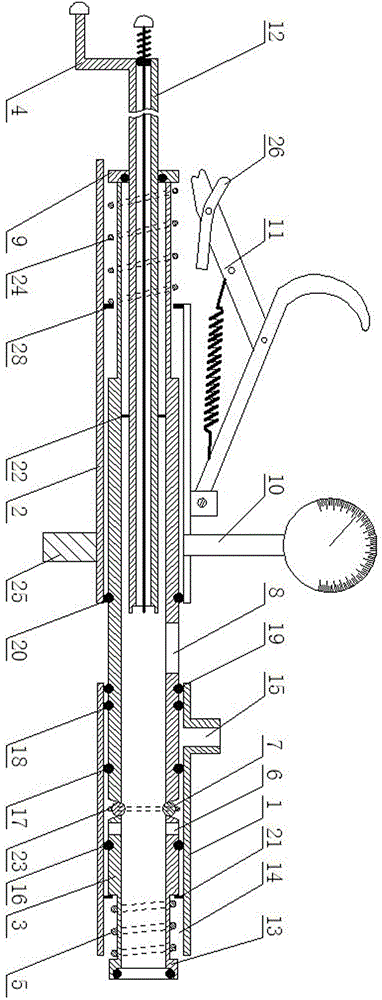

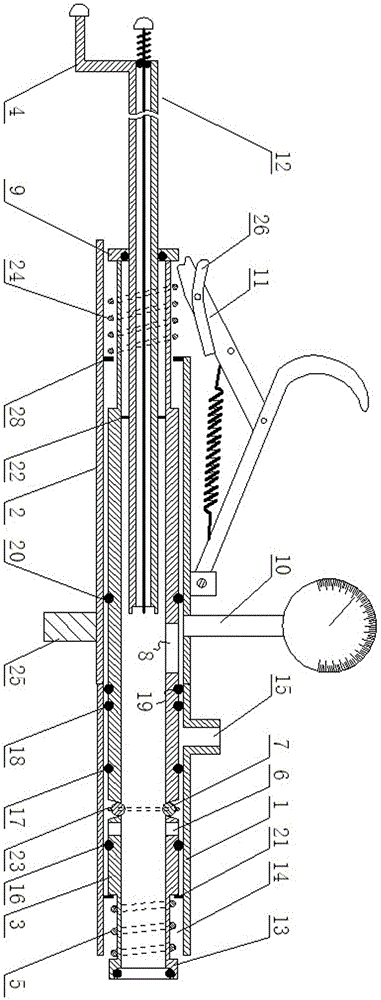

[0019] Below in conjunction with accompanying drawing, the motor vehicle tire inflation auxiliary device of the present invention is further described:

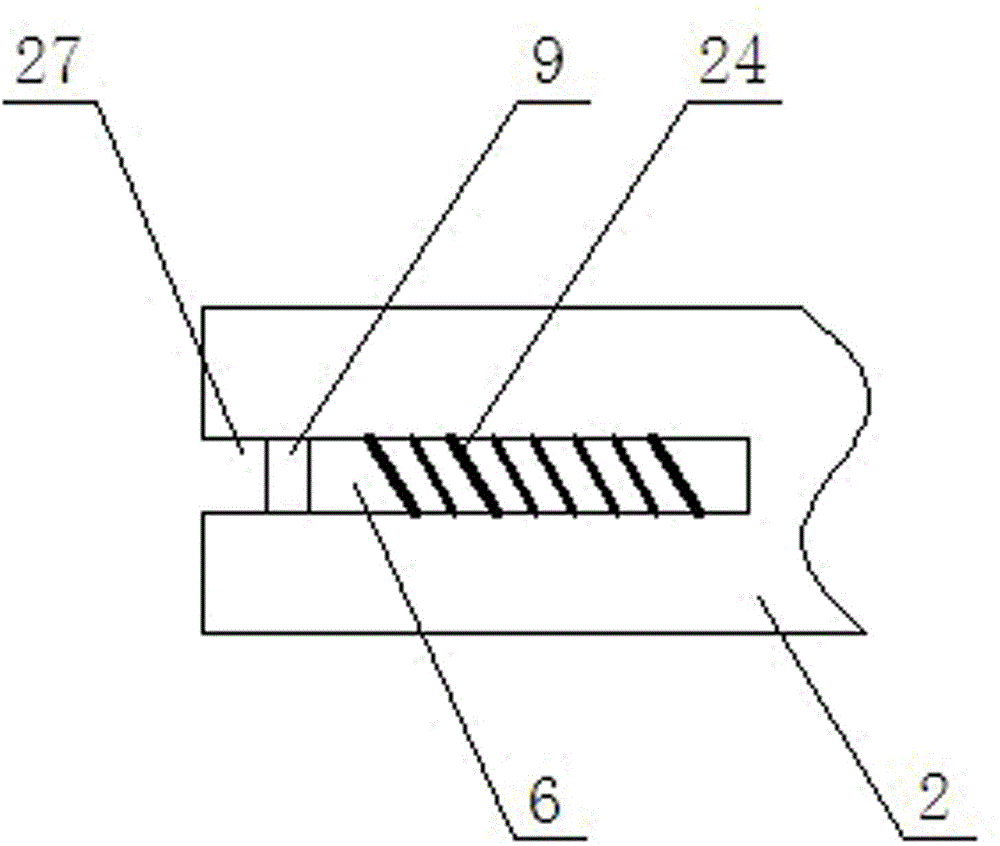

[0020] The auxiliary device for inflating motor vehicle tires consists of sleeves a1 and b2 that are placed outside the hollow inner tube 3, and the valve core rotary rod 4 is formed by extending the end of the inner tube 3 into the inner tube 3, and is characterized in that the top of the inner tube 3 It is the valve interface 13, from the groove 14 on the top of the inner tube 3, the return spring a5, the inner tube air inlet 6, the limit steel ball 7 and the valve core inlet 8 are arranged in sequence, and the end of the inner tube 3 is provided with a sealing cap 9. There is an upper spring limiter 21 between the return spring a5 and the inner edge of the groove 14; five sealing rubber rings are arranged on the inner tube 3 from the top to the end in turn; the outer casing a1 is provided with an air source inlet 15 , outs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com