Automatic injection product carrying module

A technology for injection molding products and motion modules, applied in the field of handling modules, can solve the problems of poor handling controllability, low handling accuracy, complex structure, etc., and achieve the effects of low cost, improved handling efficiency, and improved production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

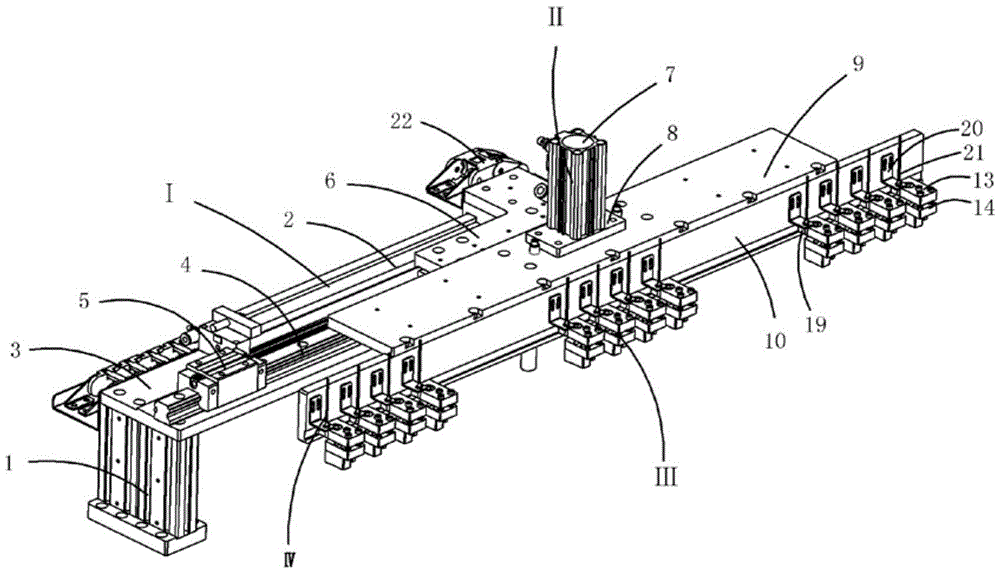

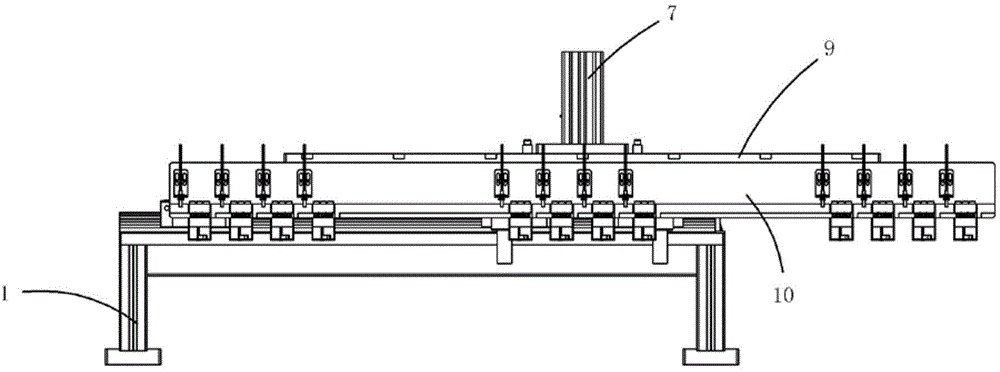

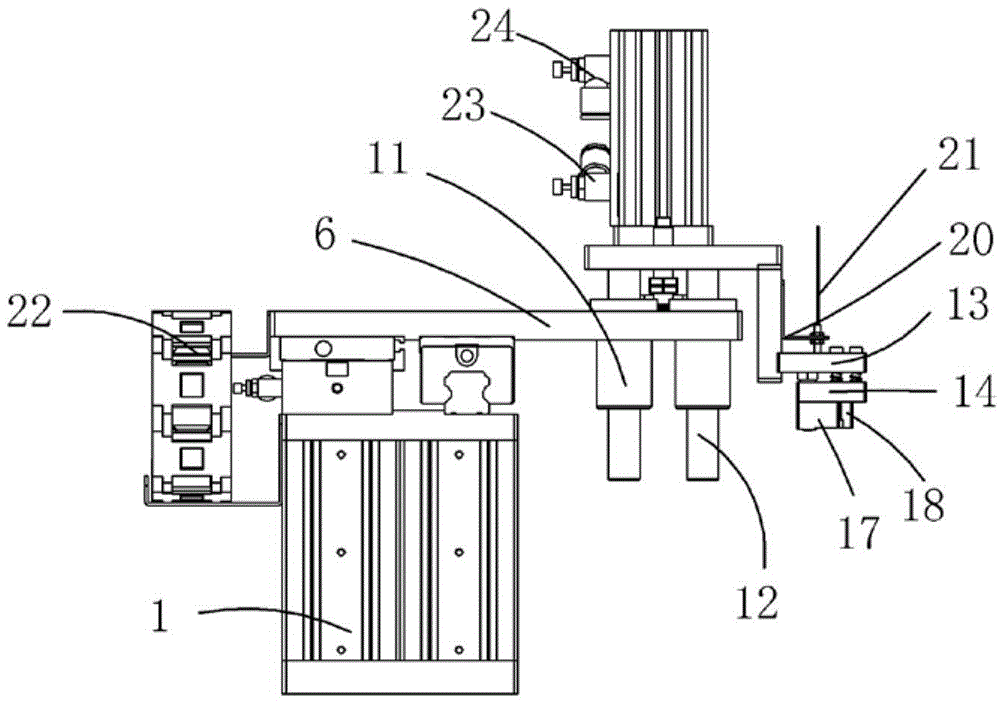

[0024] Examples, see attached Figure 1~4 , an automatic handling module for injection molding products, which includes a linear motion module I, a bushing module II, a suction nozzle module III and an optical brazing detection module IV, and the linear motion module includes a sliding table pad 1 , slider cylinder 2, cylinder pad 3, linear slide 4, linear slider 5 and slider pad 6, there are two slide pads, and the cylinder pad is fixed on the two slides On the height block, the slide cylinder and the linear slide rail are respectively fixed on the cylinder height block, the linear slide block is installed on the linear slide rail, and the slide block height block is installed on the slide table cylinder and the linear slide block, through high pressure Gas control, high-pressure gas generates thrust to the cylinder of the slide table, and the thrust is transmitted to the moved mechanism through the connection between the slider block and the linear slide rail. The linear sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com