Drinking water storage tank

A technology for drinking water and water storage tanks, which is applied in the fields of water conservation, water/sewage treatment, water/sludge/sewage treatment, etc. The effect of preventing water pollution, ensuring drinking safety and good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

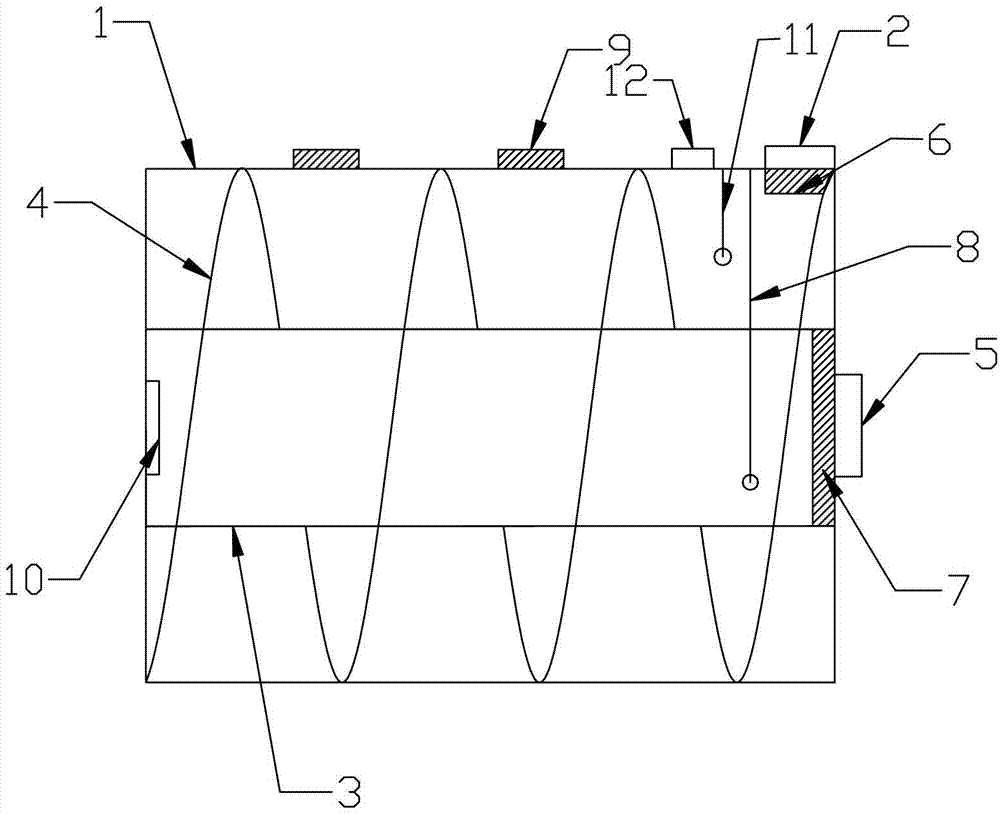

[0026] Embodiment 1: as figure 1 shown

[0027] The drinking water storage tank described in the embodiment of the present invention includes inner and outer tank bodies provided with a communication port 10, and a surrounding tank is provided in the space surrounded by the outer wall of the inner tank body 3 and the inner wall of the outer tank body 1. The diversion and noise-removing spiral plate 4 of the inner tank body, the inner and outer edges of the spiral plate are respectively connected with the outer wall of the inner tank body and the inner wall of the outer tank body; a water inlet is provided on the outer tank body 2. A water outlet 5 is provided on the inner tank body. In addition, a circle of deflector spiral plates can also be arranged in the inner tank body. The present invention erects the spiral plate in the tank body, and when the water storage tank is filled with water, the water flow flows along the spiral plate, reducing certain noise pollution. The no...

Embodiment 2

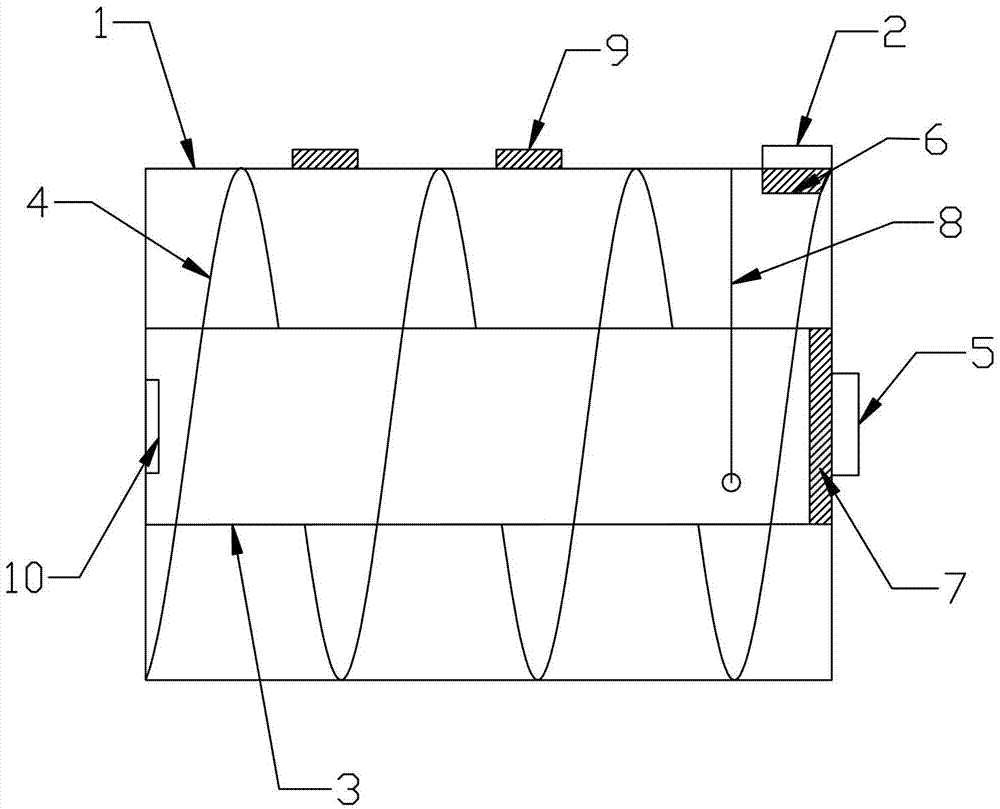

[0033] Embodiment 2: as figure 2 shown

[0034] The drinking water storage tank described in the embodiment of the present invention includes inner and outer tank bodies provided with a communication port 10, and a surrounding tank is provided in the space surrounded by the outer wall of the inner tank body 3 and the inner wall of the outer tank body 1. The diversion and noise-removing spiral plate 4 of the inner tank body, the inner and outer edges of the spiral plate are respectively connected with the outer wall of the inner tank body and the inner wall of the outer tank body; a water inlet is provided on the outer tank body 2. A water outlet 5 is provided on the inner tank body. In addition, a circle of deflector spiral plates can also be arranged in the inner tank body. The present invention erects the spiral plate in the tank body, and when the water storage tank is filled with water, the water flow flows along the spiral plate, reducing certain noise pollution. The n...

Embodiment 3

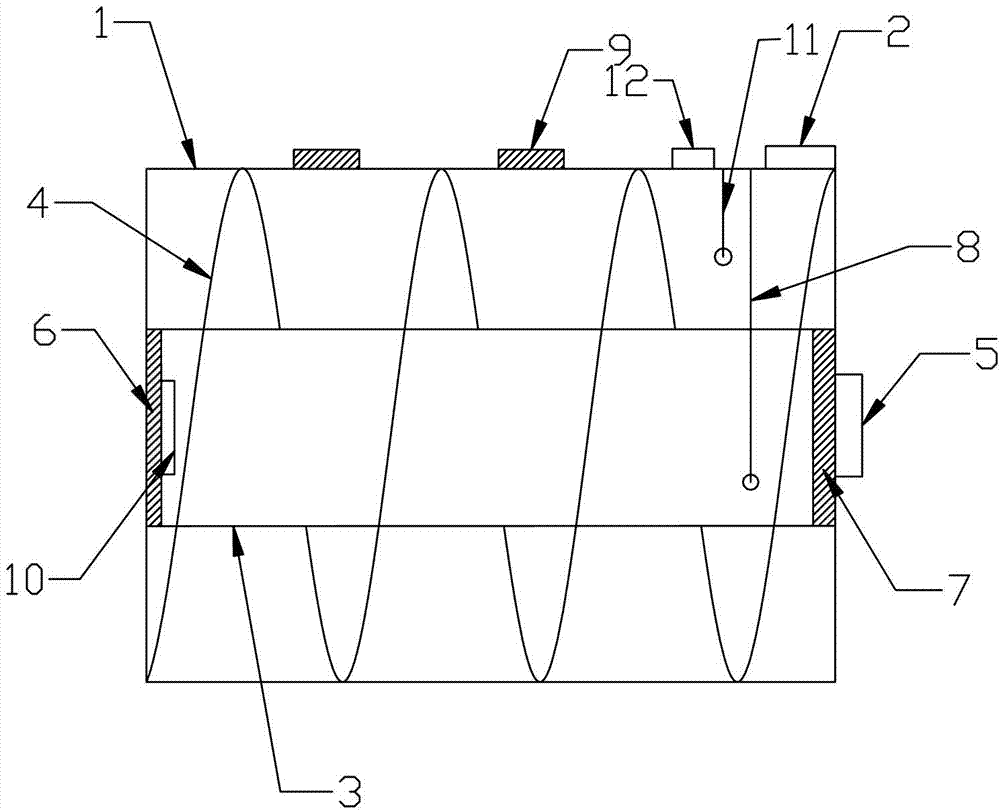

[0040] Embodiment 3: as image 3 shown

[0041] The drinking water storage tank described in the embodiment of the present invention includes inner and outer tank bodies provided with a communication port 10, and a surrounding tank is provided in the space surrounded by the outer wall of the inner tank body 3 and the inner wall of the outer tank body 1. The diversion and noise-removing spiral plate 4 of the inner tank body, the inner and outer edges of the spiral plate are respectively connected with the outer wall of the inner tank body and the inner wall of the outer tank body; a water inlet is provided on the outer tank body 2. A water outlet 5 is provided on the inner tank body. In addition, a circle of deflector spiral plates can also be arranged in the inner tank body. The present invention erects the spiral plate in the tank body, and when the water storage tank is filled with water, the water flow flows along the spiral plate, reducing certain noise pollution. The no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com