Diesel engine with swirl chamber

A vortex chamber and diesel engine technology, which is applied to mechanical equipment, engine components, machines/engines, etc., can solve the problems of limited occupied volume, large gas flow loss, etc., and achieve favorable fluid dynamic characteristics, save occupied volume, and evenly distribute Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

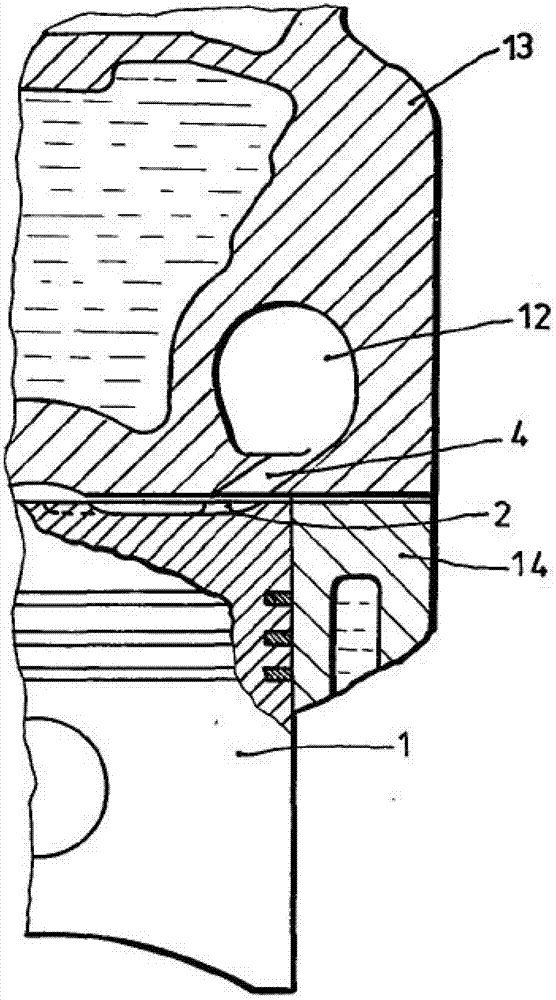

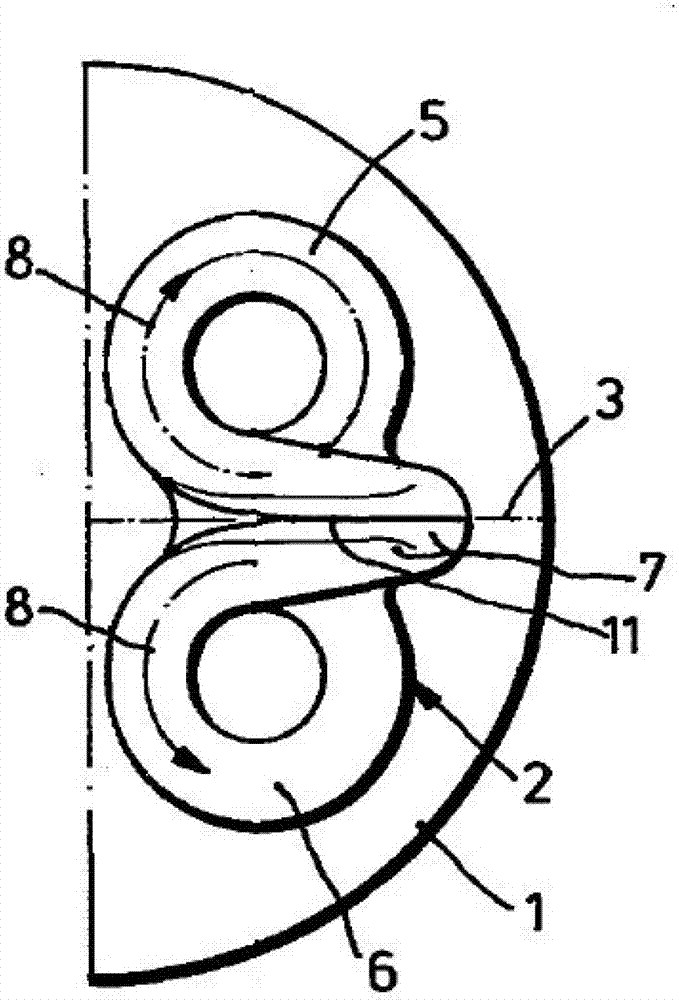

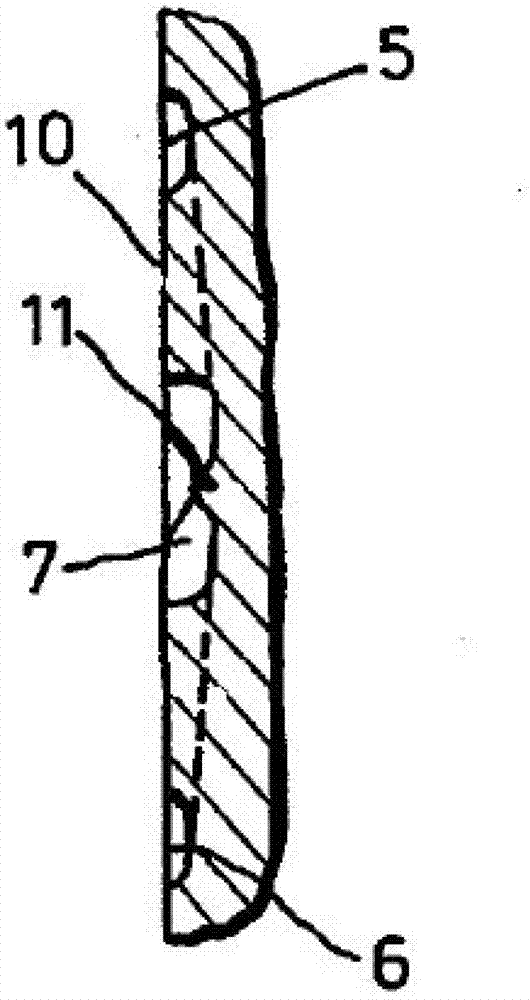

[0024] Such as figure 1 Shown is a sectional view of a diesel engine with a vortex chamber of the present invention, comprising a cylinder 14, a cylinder head 13 and a piston 1, the cylinder 14, the cylinder head 13 and the piston 1 enclosing a main combustion chamber, and the cylinder head 13 is provided with a passage 4 The vortex chamber 12 connected with the main combustion chamber, the piston top surface 10 is a wall surface of the main combustion chamber, and the piston top surface 10 is provided with a pit 2 arranged symmetrically with the passage 4, the pit 2 is an annular passage, and the pit 2 The radially overlapping portion is provided with an air intake drainage channel 7 adjacent to the opening of the channel 4 .

[0025] Further, during engine operation, fuel is injected into fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com