Hydrophilic membrane reverse flow air flue air heat and humidity recovery machine core

A hydrophilic film and air heating technology, which is applied in the energy recovery system of ventilation and heating, using air flow as shielding, household heating, etc., can solve the problem of low energy and moisture recovery efficiency and small recovery efficiency of heat transfer channels , large installation volume and other issues, to achieve the effect of improving heat and moisture transfer capacity, improving energy effect, and sufficient heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

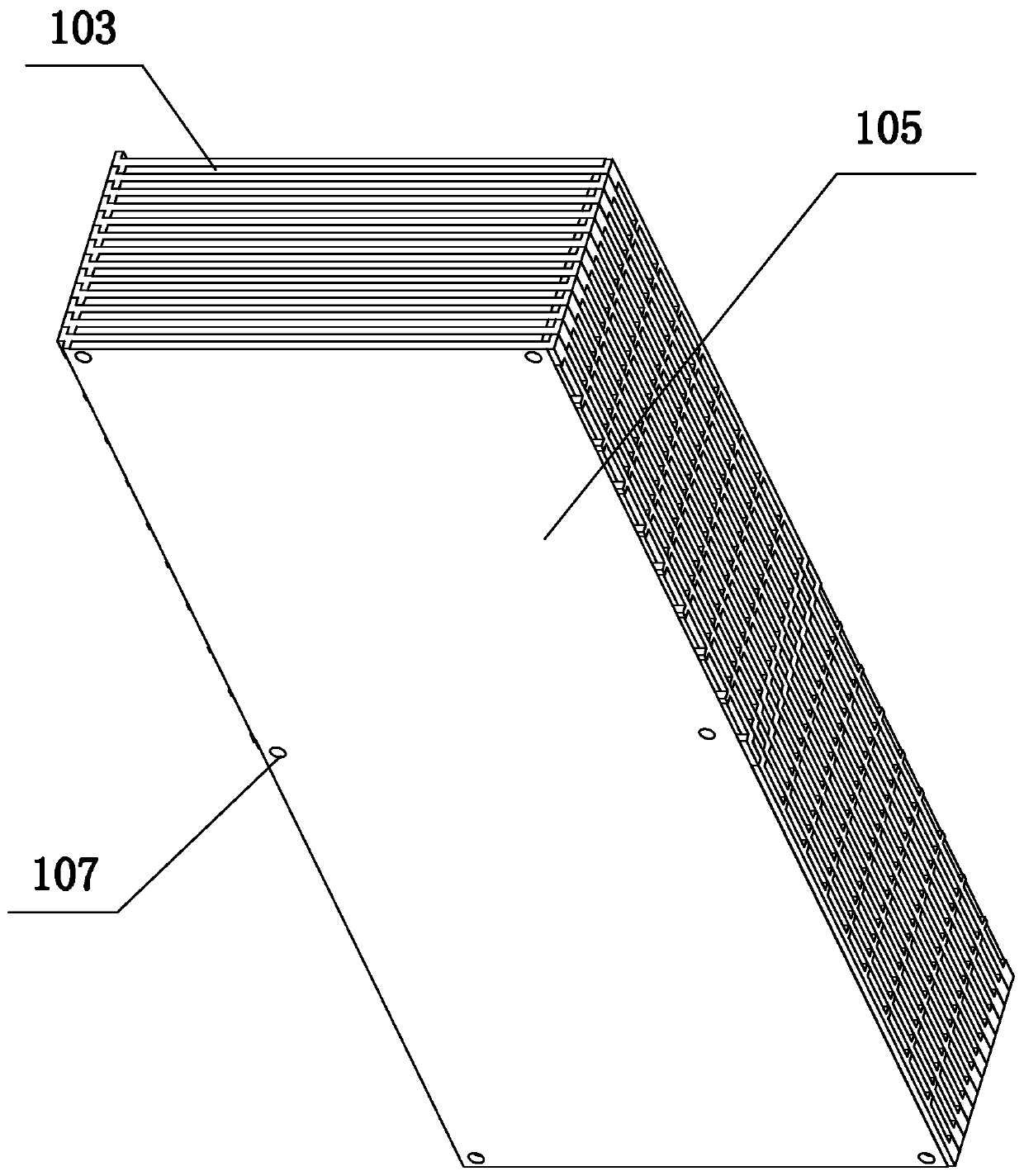

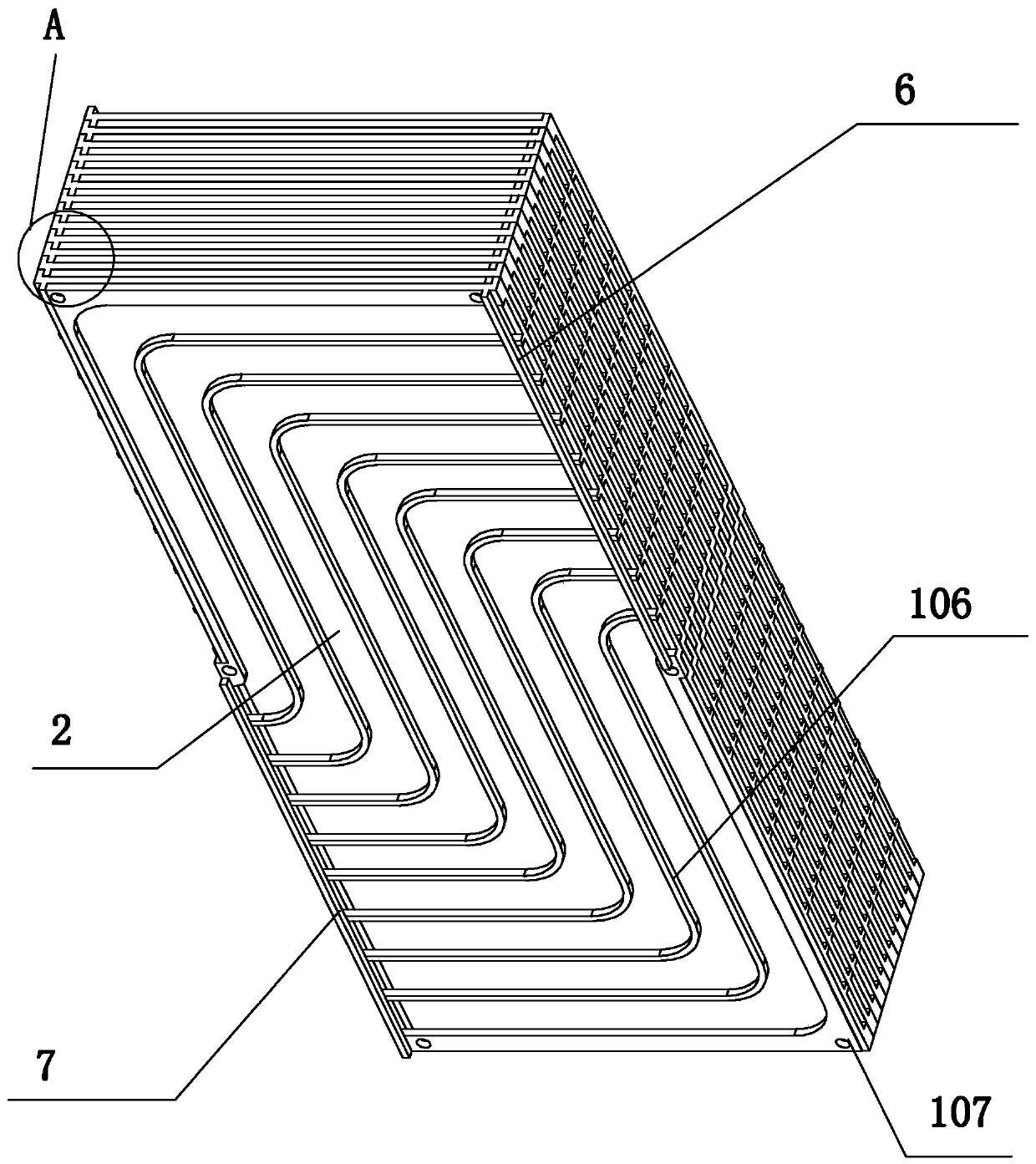

[0044] Such as Figure 1 to Figure 10 As shown, the air heat and moisture recovery core of the hydrophilic film reverse flow air duct, referred to as the heat and moisture recovery core 1, as shown in figure 1 , figure 2 As shown, it includes a mesh plate, a heat transfer film 103, six fixing rods 104 and a cover plate 105;

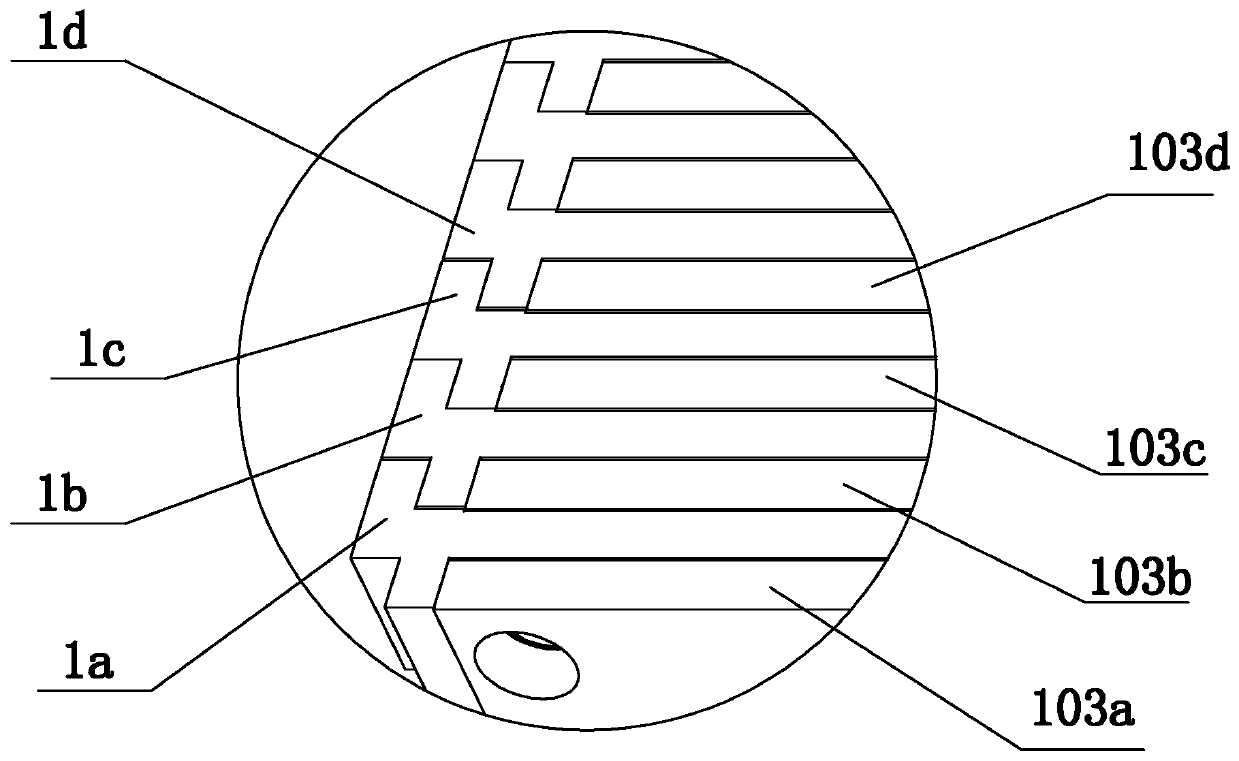

[0045] Such as Figure 3 to Figure 7 As shown, the screen is rectangular, and the screen is divided into an upper layer 10, a middle body layer 11 and a lower layer 12 in the upper and lower directions. The middle body layer 11 includes 8 channel isolation strips 106, and each adjacent 2 channel isolation bars 106 to form an air flow channel; the upper layer 10 and the lower layer 12 are used for installing the heat transfer film 103 and the positioning of the mesh plate, and the mesh plate is provided with 6 fixed rod perforations 107, which are used as the fixed rod 104 for positioning during assembly; The board includes several pieces of fresh air...

Embodiment 2

[0067] The hydrophilic membrane is a heterogeneous hydrophilic membrane;

[0068] The heterogeneous hydrophilic membrane is immersed in a hydrophilic membrane on a composite material membrane using a heterogeneous membrane substrate. The heterogeneous membrane is a patented heat and moisture transfer membrane (see the publication number: CN202463073U for details, the patent number: 2011204094071, and the invention name is : a kind of out-of-phase film and out-of-phase film core);

[0069] Due to the significant difference in the thermal conductivity of the substrate, the function of heat and moisture transfer has its own characteristics; the substrate of the heterogeneous film is a non-metallic material, the thermal conductivity is only 0.04w / mk, and the film thickness is calculated as 0.12mm, and its heat transfer is 333w / k ;The heat release coefficient of the air in the air duct is about 2200w / m 3 k, the heat release of air in the air duct is based on the air flow rate of 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com