Intelligent multi-span greenhouse mushroom house remote control system

A remote control system and technology for greenhouse mushroom houses, which are applied in the field of remote control systems for intelligent multi-span greenhouse mushroom houses, can solve the problems of waste of technicians, lack of intelligence, and factory stay, so as to save costs, shorten management practices, and facilitate The effect of centralized control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

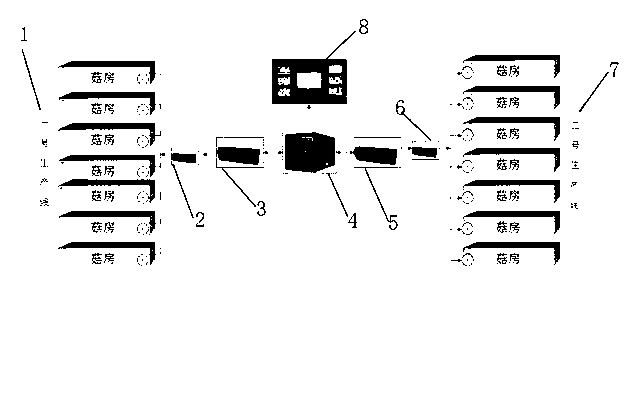

[0011] Intelligent multi-span greenhouse mushroom house remote control system, which includes No. 1 production line 1, No. 2 production line 7, No. 1 wireless network control system 2, No. 2 wireless network control system 6, No. 1 data control system 3, No. 2 data control system 5. Central server 4 and monitoring command center system 8. No. 1 production line 1 is connected with No. 1 wireless network control system 2, No. 2 production line 7 is connected with No. 2 wireless network control system 6, and No. 1 wireless network control system 2 is connected with No. 1. Data control system 3 is connected, No. 2 wireless network control system 6 is connected to No. 2 data control system 5, No. 1 data control system 3 and No. 2 data control system 5 are respectively connected to the central server 4, and the central server 4 is connected to the monitoring command center system 8Connect.

[0012] The No. 1 production line 1 includes seven mushroom houses. Each mushroom house is equip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com