Anti-mechanical shock armature device used for moving-iron receiver/ speaker

A mechanical shock and receiver technology, applied in the direction of sensors, electrical components, etc., can solve the problem that the mechanical shock resistance of receiver/speaker products cannot reach the desired effect, the mechanical shock resistance of moving iron receiver/speaker is poor, and the material cost is increased. and manufacturing costs and other issues, to achieve the effect of good market promotion value, improved mechanical shock resistance, and easy conversion process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and a preferred embodiment.

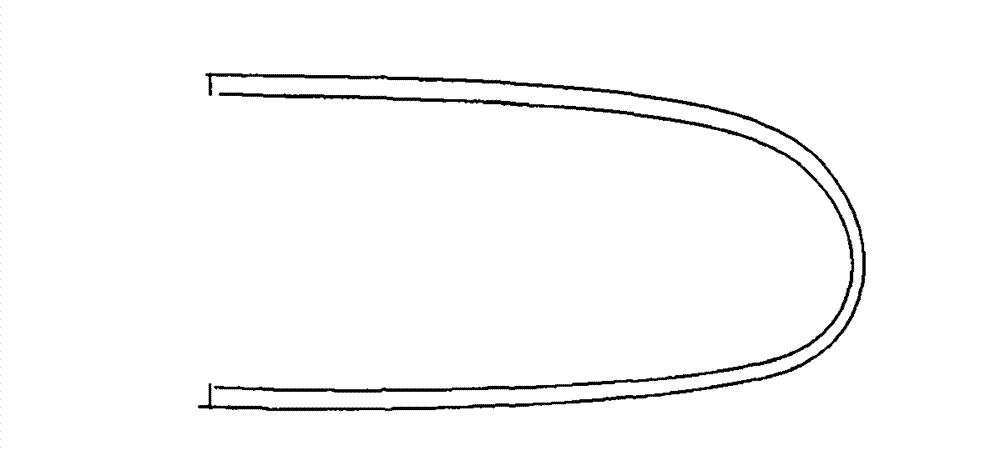

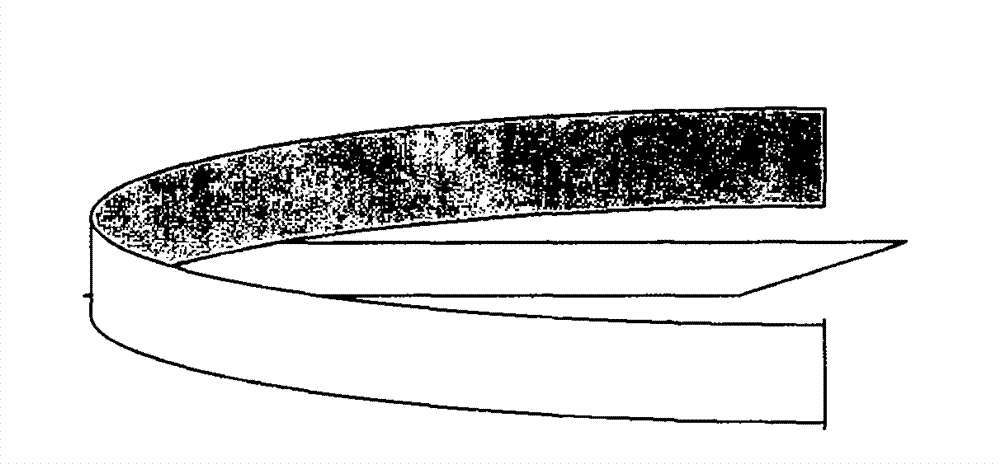

[0024] refer to Figure 4-6 , this embodiment relates to an anti-mechanical shock armature device B2 for a moving iron receiver / speaker, which includes a vibration transduction part A1, an anti-mechanical shock device A2 and a magnetic connection part A3. The aforementioned vibration transduction part A1 is located in the middle of the anti-mechanical shock armature device B2 and is a planar structure, on which there are convex and concave anti-mechanical shock devices A2 orthogonal to the planar structure. The magnetic connection part A3 at the side and the tail is connected to form the anti-mechanical shock armature device B2.

[0025] Since the improved design of the vibration transduction part A1 and the magnetic connection part A3 is a mutual orthogonal structure, and the anti-mechanical shock device A2 is a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com