Dichloromethane waste gas treating method and system thereof

A dichloromethane and waste gas treatment technology, applied in separation methods, chemical instruments and methods, organic chemistry, etc., can solve problems such as damage to the health of operators, harm to the central nervous system and respiratory system, pollution, etc. Secondary pollution, good economic benefits, compact and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

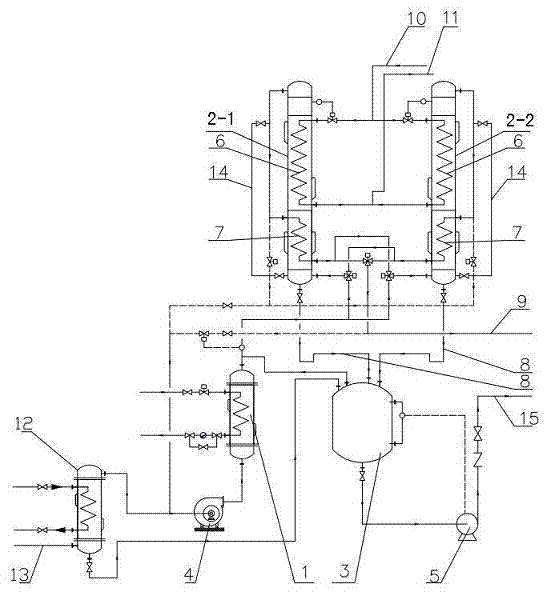

[0029] Such as figure 1 The methylene chloride waste gas treatment system shown includes a methylene chloride waste gas inlet pipe 13, a pretreatment system, a condensation system, a recovery storage tank 3, a fan 4, and a solvent pump 5. The pretreatment system consists of a condenser 12 and a condensing system. The methylene chloride exhaust gas inlet pipe is connected to the lower end side of the condenser. The pipe connecting the condenser and the gas-to-air heat exchanger is provided with a fan 4, and the outlet of the fan exchanges heat with the gas The bottom pipe connection of the device.

[0030] The condensing system consists of two condensing towers, which are divided into a first condensing tower 2-1 and a second condensing tower 2-2. The first condensing tower and the second condensing tower are connected in series through pipelines. Each condensing tower is composed of a liquid nitrogen cryogenic section 6 formed by a condenser tube and a gas-gas exchange pre-coolin...

Embodiment 2

[0035] A methylene chloride waste gas treatment method using the system in Example 1, specifically as follows:

[0036] Step 1. Set the concentration to 1g / m 3 Above, air volume at 60m 3 The methylene chloride waste gas with a temperature above 20~35℃ and a temperature of 20~35℃ is transported to the tube condenser in the pretreatment system for cooling treatment, so that the temperature is reduced to 0~10℃, and the cooling medium is 5℃ freezing The brine then enters the condensing system.

[0037] Step 2: The exhaust gas after cooling treatment enters the condensation system for cryogenic treatment, and the cooling medium is liquid nitrogen. The condensing system consists of two condensing towers. Each condensing tower is divided into two sections, consisting of a liquid nitrogen cryogenic section and a gas-gas exchange pre-cooling section. After entering the tower, the exhaust gas first goes to the shell side and passes through the liquid nitrogen cryogenic section for cryogenic ...

Embodiment 3

[0040] The concentration is 2g / m 3 , Air volume at 100m 3 / h, the methylene chloride waste gas with a temperature of 30°C is piped to the tube condenser in the pretreatment system for cooling treatment, and the temperature is reduced to 10°C. The cooled waste gas enters two condensation towers for deep cooling. Cooling treatment, the cooling medium is liquid nitrogen. After entering the tower, the exhaust gas will go through the shell side and pass through the liquid nitrogen cryogenic section for cryogenic treatment. The temperature will be cooled to -94℃. Then the low-temperature tail gas will go through the tube side. After the gas-gas heat exchange, the liquid nitrogen is recovered Part of the cold energy after cryogenic cooling will then enter the second stage of condensation for cryogenic treatment to reduce the temperature of the exhaust gas to -144°C, and then discharge the treated exhaust gas at high altitude with an emission temperature of -40°C. The partial analysis t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap