Looping mechanism of towel loom

A technology of raising mechanism and towel loom, which is applied in looms, fabrics, textiles, etc., and can solve problems such as the inability to change the height of the loops and the fixed beating stroke of the beating-up reed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

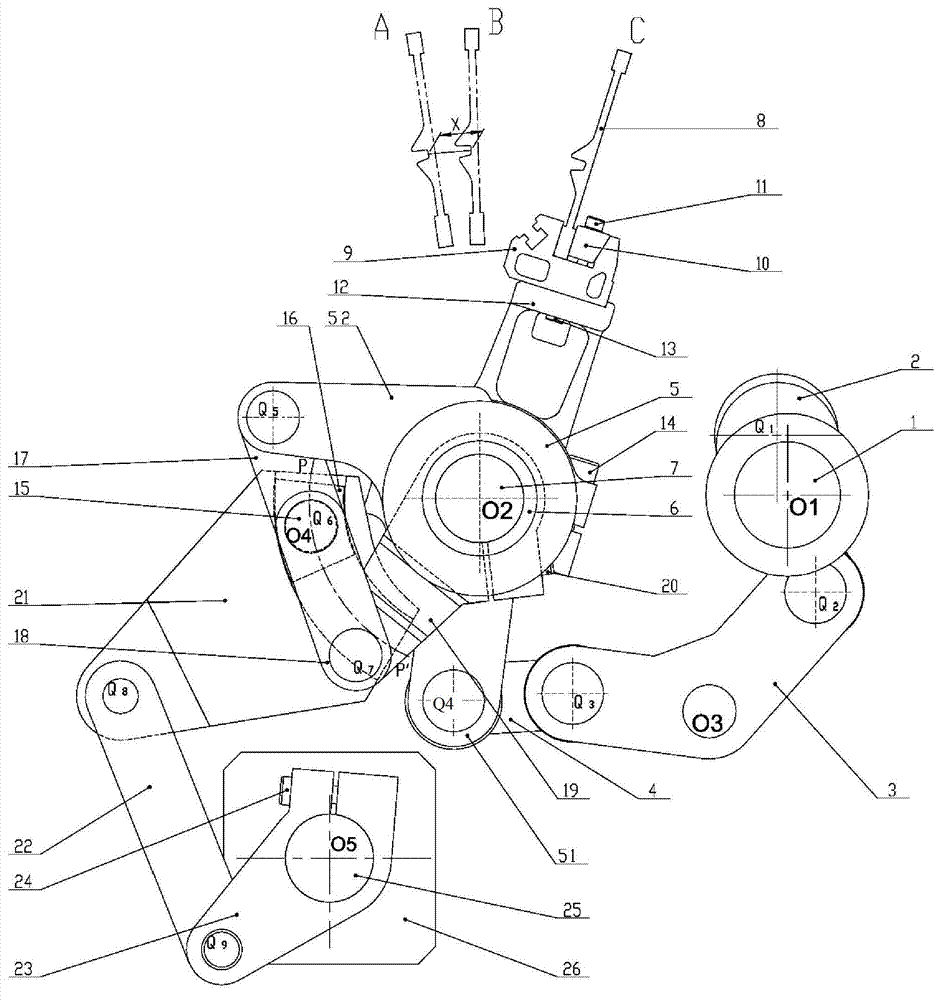

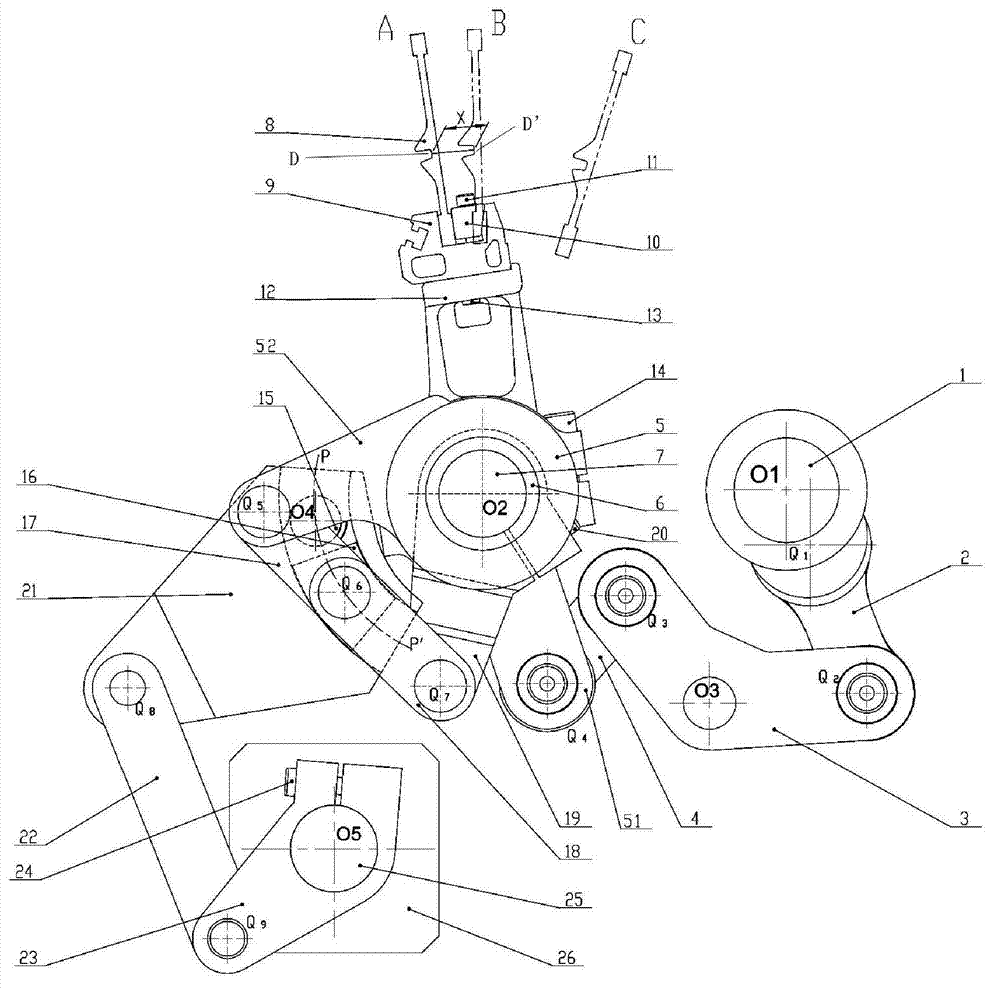

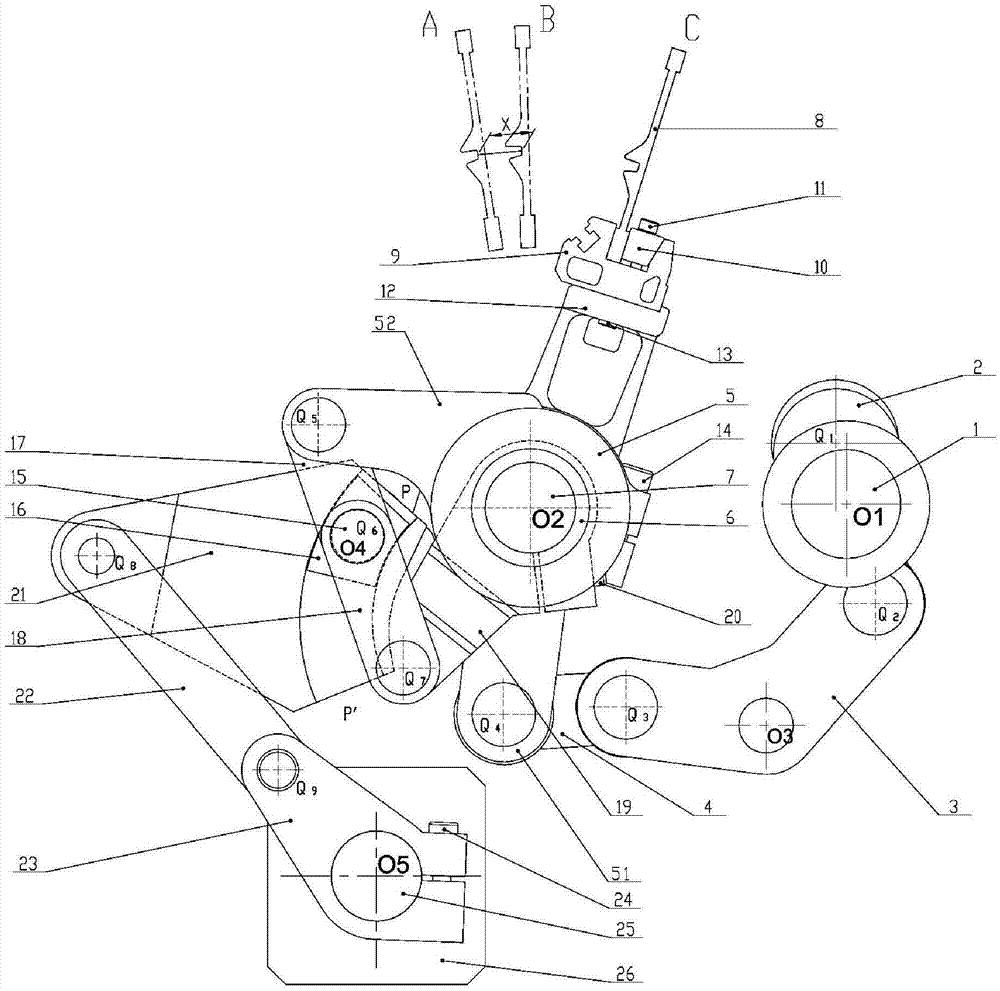

[0022] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, a raising mechanism of a towel loom according to the present invention includes a frame (not shown in the figure), a beating device and a driving device, and the beating device and the driving device are both arranged in the frame, The beating-up device is fixedly connected with a rocking shaft 7, wherein the rocking shaft 7 is arranged on a second fulcrum O2 in the frame, and a swing arm 19 is fixedly arranged radially on the rocking shaft 7, A first link mechanism is arranged between the drive device and the swing arm 19, and a sixth hinge point Q6 is included in the first link mechanism, and a drive motor is fixedly arranged in the frame 26, the output shaft 25 of the drive motor 26 is connected with a second link mechanism, and the second link mechanism includes a fan-shaped swing arm 21, and the fan-shaped swing arm 21 is arranged on a support On the shaft 15, the fulcrum 15 is set on a fourth ful...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com