Aluminum alloy frame and ceramic thin plate curtain wall utilizing aluminum alloy frame

A technology of ceramic thin plates and aluminum alloys, applied in walls, building components, buildings, etc., can solve the problems of ceramic thin plates falling off and other problems, achieve high production efficiency, accurate positioning accuracy, and improve the effect of wind pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

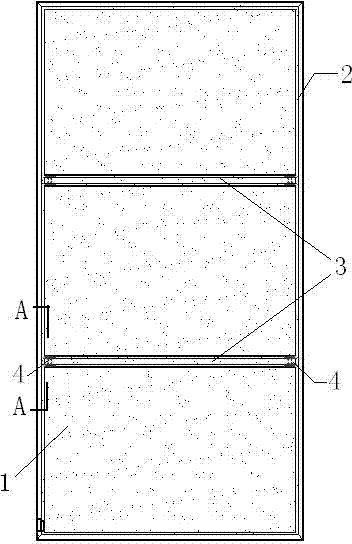

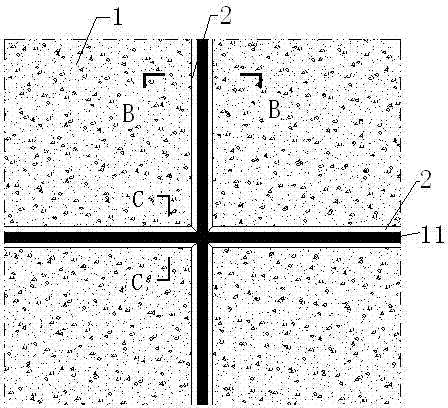

[0022] The present invention will be further explained below in conjunction with the drawings.

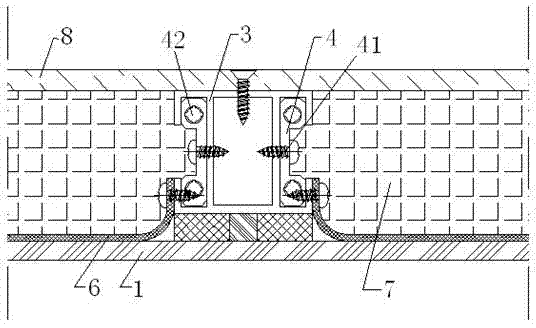

[0023] Such as Image 6 As shown, it is an aluminum alloy edge 21, and the periphery of the aluminum alloy frame 21 and the ceramic sheet bonding layer 1 is configured as a edging frame structure 20 that wraps the periphery of the ceramic sheet. The cross section of the aluminum alloy frame includes a hollow rectangular main body 22, and an outer C-shaped frame structure 23 and an inner C-shaped frame structure 24 extending outwardly along two adjacent sides of the rectangular main body. The outer C-shaped frame structure 23 is used In order to realize the edging and bonding with the periphery of the ceramic thin plate, the inner C-shaped frame structure 24 is used to install the aluminum alloy frame on the column or cross bar through the pressing plate. The rectangular main body of the aluminum alloy frame is provided with a screw hole 25 for fixing with a connecting piece.

[0024] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com