Minitype dynamic pulling-pressing experiment system with preload

An experimental system and preloading technology, applied in the direction of applying repetitive force/pulsation force to test the strength of materials, which can solve the problems of stress wave propagation, inability to integrate dynamic tension and compression experiments, etc., to improve efficiency and promote modularity. simplification and facilitation, and achieve the effect of integration

Inactive Publication Date: 2013-07-17

BEIJING INSTITUTE OF TECHNOLOGYGY

View PDF10 Cites 27 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The purpose of the present invention is to provide a preloaded miniature dynamic tension-compression test system to solve the problem of influence on stress wave propagation in t

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

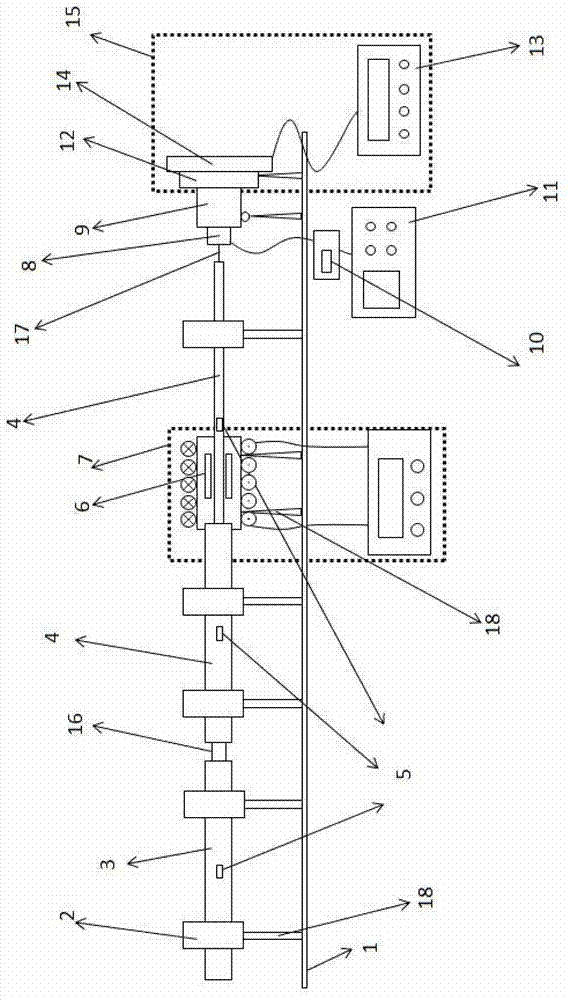

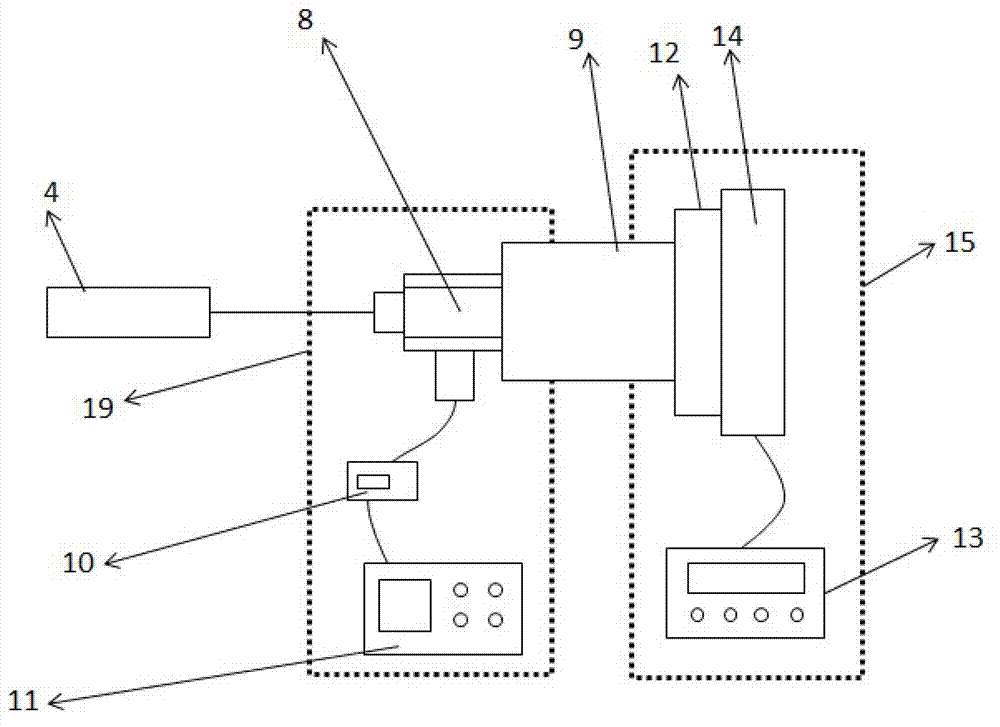

The invention discloses a minitype dynamic pulling-pressing experiment system with preload, and relates to a minitype experiment system which can carry out dynamic tension on materials such as film or fibre and can perform dynamic compression on small block test specimens such as explosive single crystals, and belongs to the technical field of dynamic impact experimental mechanics. An improved Hopkinson pressure lever device and a minitype Kolsky pressure lever device are ingeniously combined on an experiment platform through a pressure pulling common variable cross-section trip rod with an optimized design, the film or a fiber material test specimen to be detected is tensioned in advance through the designed preloading device, and an error in stress wave one-dimensional transmission of an experiment is reduced; and a magnetic resistance type coil launcher is combined with a cylindric pill launcher, a simple two-rod piece system and the preloading device, and namely, the dynamic tension and dynamic impact experiment is realized. The minitype dynamic pulling-pressing experiment system provided by the invention has the advantages that the structure is compact, the use is convenient, and the minitype dynamic pulling-pressing experiment system is suitable for dynamic tension mechanical property research.

Description

technical field [0001] The invention relates to the field of dynamic impact test mechanics, in particular to a miniature dynamic tension-compression test system with preload. Background technique [0002] In many cases, such as the bumping and impact of automobiles, the launch of spacecraft, etc., materials or structures are often subjected to dynamic loads, especially the mechanical response under impact loads is an important mechanical performance parameter of materials. The separate Hopkinson bar (Hopkinson) dynamic mechanical testing system can successfully test the dynamic compression and tensile properties of materials. The mechanical properties of materials under two opposite high strain rate loads are of great significance to the application of materials. At the same time, the dynamic performance test of micro-specimen is also becoming a new demand. However, usually separate dynamic compression experiments and tension experiments need to be carried out on different ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N3/36

Inventor 刘战伟于琦陈喜民

Owner BEIJING INSTITUTE OF TECHNOLOGYGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com