Multistage micro-injection device

An injection device and a micro-quantity technology, applied in the direction of surface tension analysis, etc., can solve problems such as the inability to accurately control the amount of liquid injection, and achieve the effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

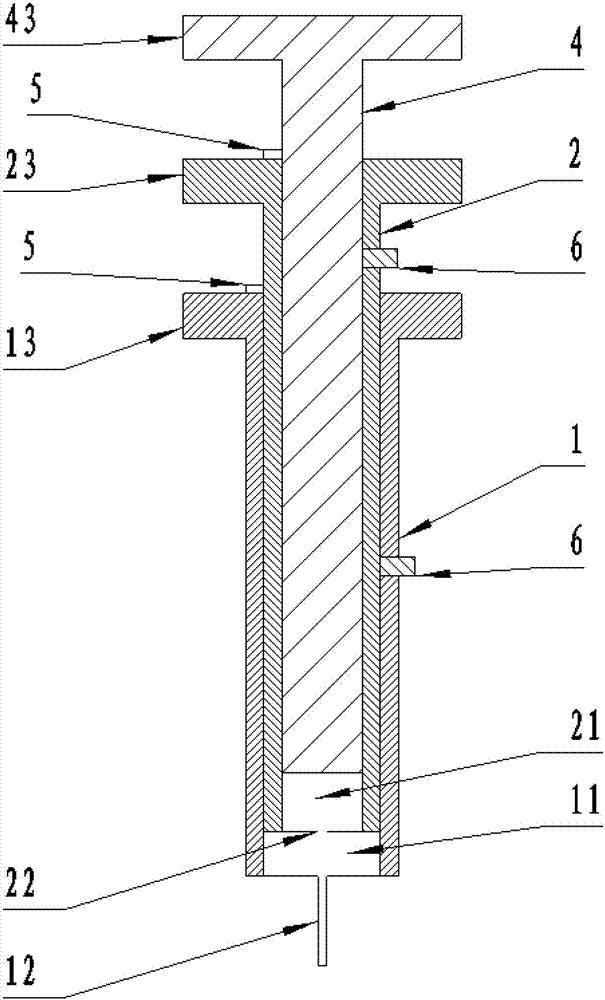

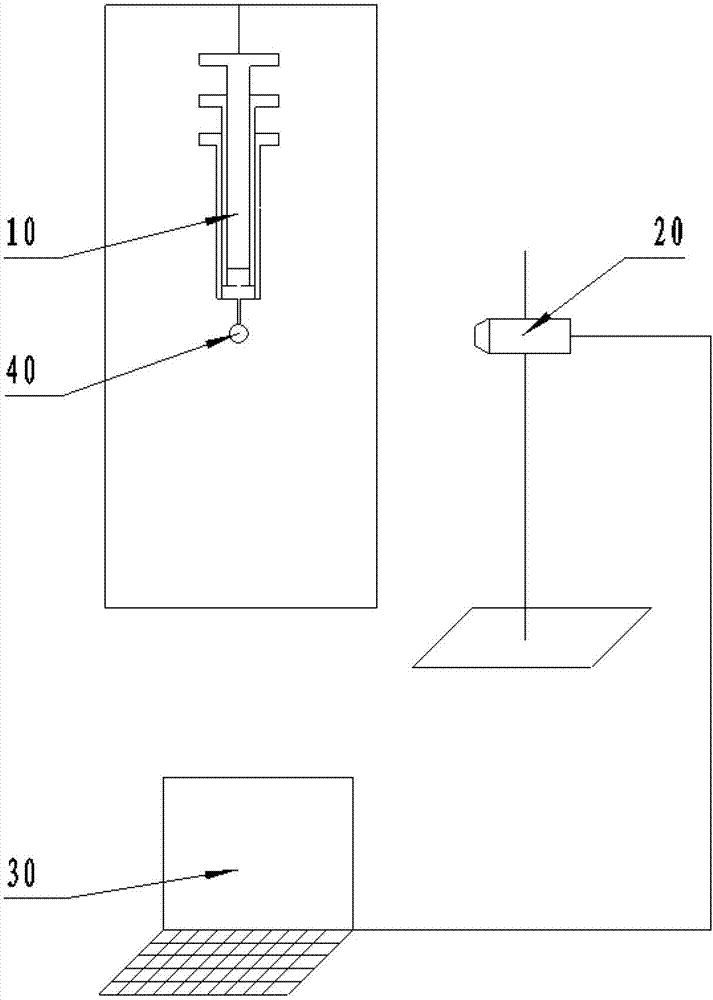

[0025] The multi-stage micro-injection device of the present invention will be described in detail below with reference to the accompanying drawings. A multi-stage micro-injection device 10, comprising an outer hanging dropper 1, a first-stage threaded cavity piston tube 2, and a solid threaded piston 4, which are sequentially socketed from the outside to the inside; the outer hanging dropper 1 is in the shape of a cylinder with one end closed, The inside of the externally suspended dropper 1 is a first cavity 11, and the closed end of the externally suspended dropper 1 is provided with a first-level injection port 12; the first-level threaded cavity piston tube 2 is cylindrical with one end closed, and the first-level thread The closed end of the hollow piston tube 2 is set in the outer hanging dropper 1, the open end of the first-stage threaded cavity piston tube 2 is set outside the outer hanging dropper 1, and the inside of the first-stage threaded cavity piston tube 2 is t...

Embodiment 2

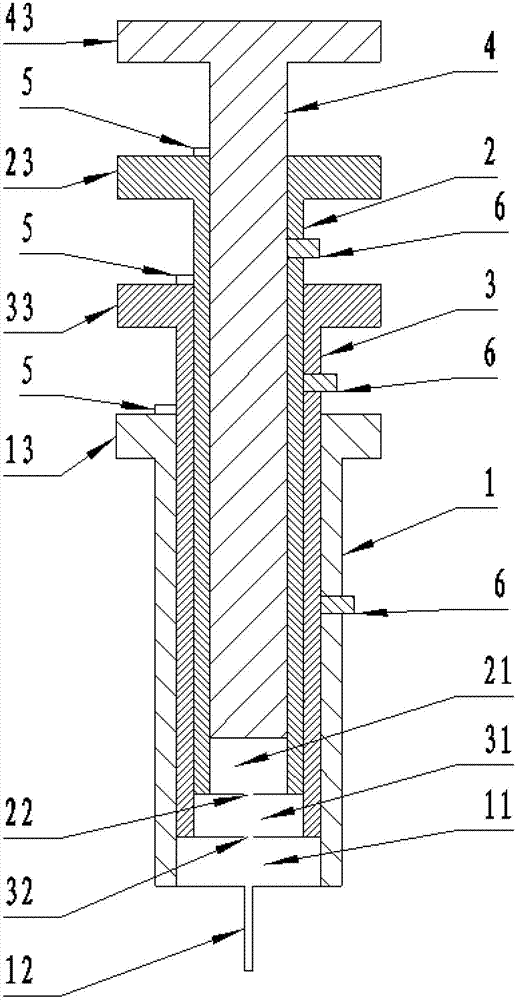

[0031]This embodiment is an improvement on Embodiment 1, thus including all the technical features of Embodiment 1. The multi-stage micro-injection device 10 in this embodiment not only includes an externally suspended dropper 1, a first-stage threaded cavity piston tube 2, and a solid threaded piston 4 that are sequentially socketed from outside to inside; The first-stage threaded cavity piston tubes 2 are socketed through the second-stage threaded cavity piston tube 3; the second-stage threaded cavity piston tube 3 is cylindrical with one end closed, and the closed end of the second-stage threaded cavity piston tube 3 is set outside In the hanging dropper 1, the open end of the secondary threaded cavity piston tube 3 is arranged outside the external hanging dropper 1, the inside of the secondary threaded cavity piston tube 3 is a third cavity 31, and the secondary threaded cavity piston tube 3 The closed end of the closed end is provided with a third-level injection port 32,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com