Holder, holder with flat conductor and assembly of holder with electrical connector

A flat conductor and electrical connector technology, applied in the parts, connections, circuits and other directions of the connection device, can solve problems such as difficulties, achieve a good connection state, and prevent damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

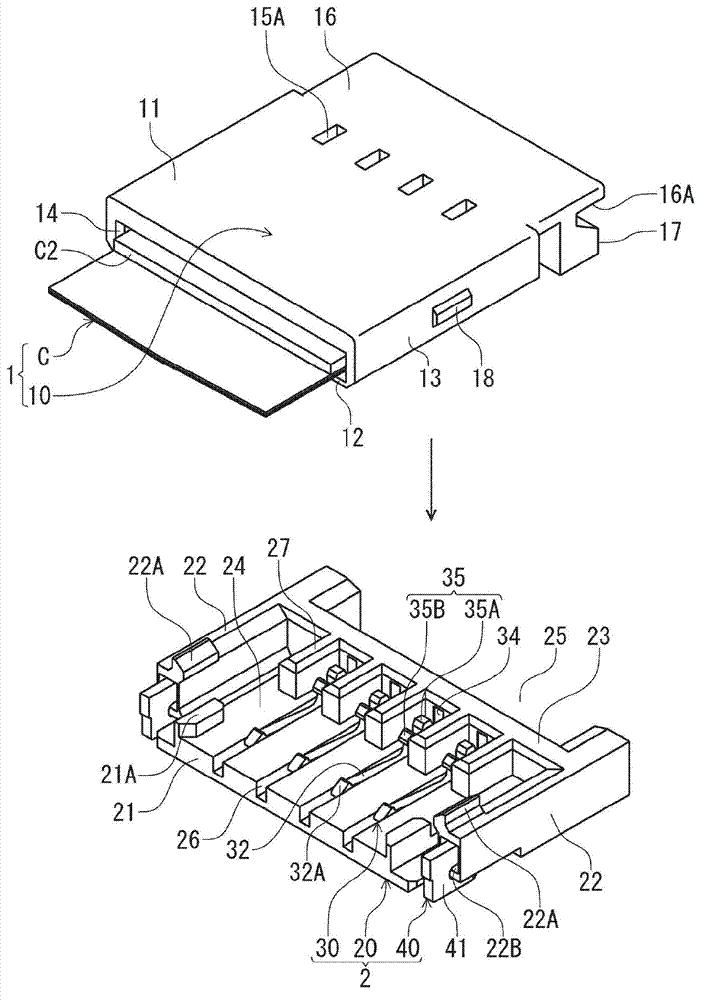

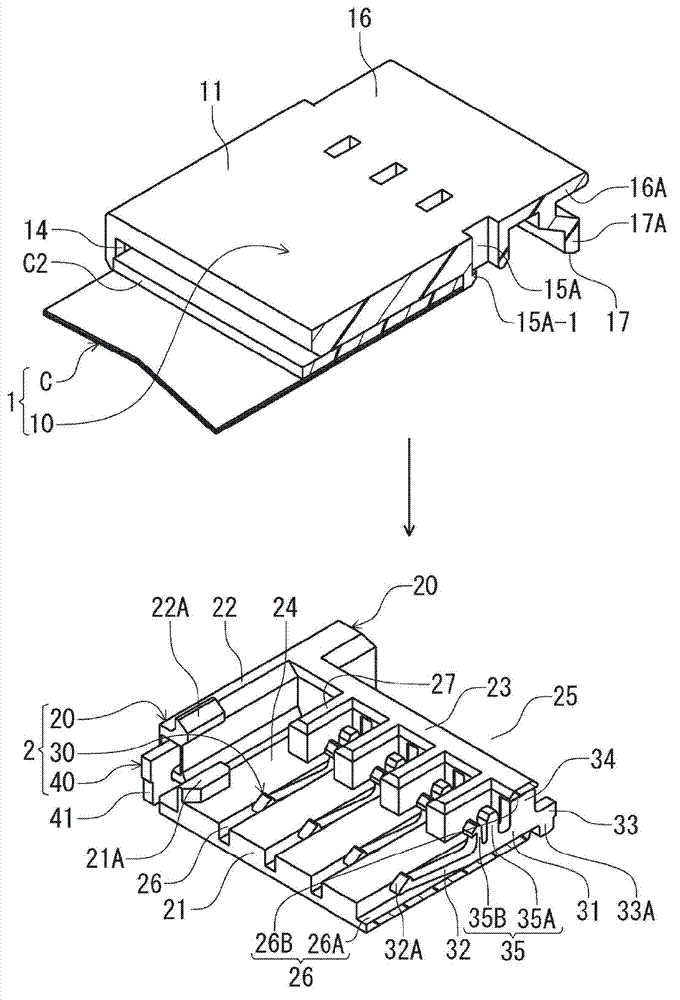

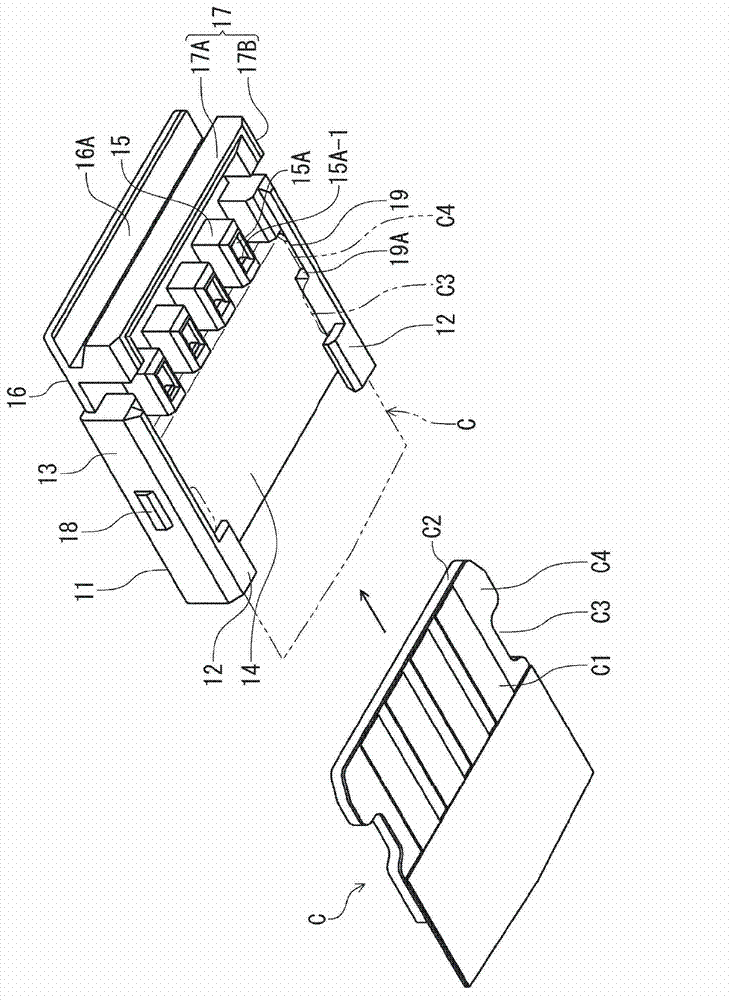

[0054] figure 1 It is a perspective view showing the flat conductor-attached holder and the electric connector of this embodiment, and shows the state before connection. figure 2 yes figure 1 A perspective sectional view of a flat conductor holder and an electrical connector of , showing a section at the position of the terminal in the width direction of the flat conductor. image 3 yes figure 1 The perspective view before assembly of the holder with the flat conductor is shown from the lower side, showing the state before assembly when the front end portion of the flat conductor is separated from the holder. Additionally, in the image 3 In , the outline of the front end portion of the flat conductor when it is attached to the holder is indicated by a two-dot chain line.

[0055] Such as figure 1 As shown, the holder 1 with a flat conductor of this embodiment is assembled by attaching the front end portion of the flat conductor C to the holder 10 . In this holder 1 wit...

no. 2 approach

[0091] In the first embodiment, the terminal 30 of the connector 2 does not have a part to engage with the flat conductor C, but Figure 6 The present embodiment shown is different from the first embodiment in that the terminal has a protrusion 76 engaged with the flat conductor C at the rear.

[0092] Below, according to Figure 6 This embodiment will be described. Figure 6 It is a perspective cross-sectional view of the flat conductor-attached holder 3 and the connector 4 of the present embodiment, showing a cross-section at the position of the terminal 70 in the width direction of the flat conductor C. The structure of the flat conductor C of this embodiment is the same as that of 1st Embodiment except the hole part C5 mentioned later is formed. exist Figure 6 In , with respect to the flat conductor C, the same symbols are attached to the parts corresponding to those of the first embodiment. In addition, the structure of the holder of this embodiment is the same as th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com