Amine and amine oxide surfactants for controlling herbicide spray drift

A surfactant, tertiary amine oxide technology, used in applications, biocides, animal repellents, etc.

- Summary

- Abstract

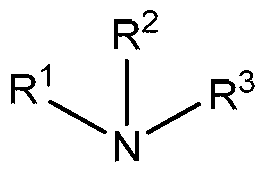

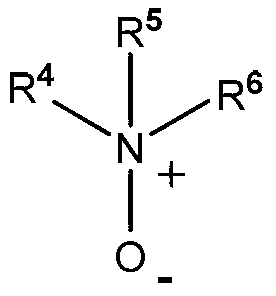

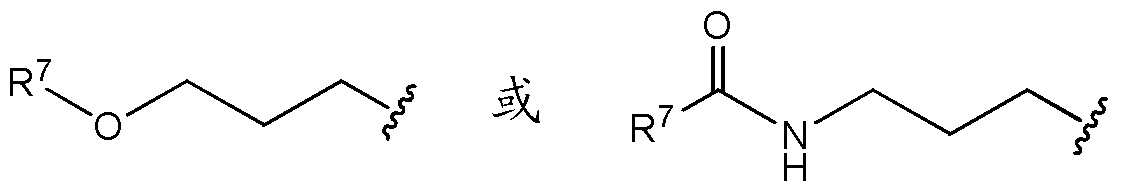

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: herbicide spray sample

[0041] Contains 228 grams acid equivalent per liter (g ae / L) of choline salt of 2,4-D, 240 g ae / L of dimethyl ammonium salt of glyphosate (DMA), 60 g / L propylene glycol and 36 g / L Herbicide concentrates (on a dry weight basis) of the indicated tertiary amine oxide surfactants were prepared as follows using aqueous samples of the following amine oxide surfactants:

[0042] 1. C, 30% w / w cocoalkyl dimethylamine oxide solution in water

[0043] 2. MO, 30% weight / weight (w / w) solution of tetradecyldimethylamine oxide in water

[0044] 3. MCO,30%w / w(C 14 and C 16 ) solution of linear alkyl dimethylamine oxide in water

[0045] 4. LO, 30% w / w lauryldimethylamine oxide solution in water

[0046] 5. LO, 30%w / w (C 12 and C 14 ) solution of linear alkyl dimethylamine oxide in water

[0047] 6. C / 12, 50% w / w solution of dihydroxyethyl cocoalkylamine oxide in water

[0048] 7. DO, 30% w / w solution of decyldimethylamine...

Embodiment 2

[0054] Example 2: Herbicide Concentrate

[0055] Herbicide containing 114g ae / L 2,4-D DMA, 120g ae / L glyphosate DMA, 30g / L propylene glycol and 18g / L (based on dry weight) of the tertiary amine oxide surfactant listed in Example 1 Dose concentrates were prepared as follows. First add 20.56 g of a 55.44 wt% ae2,4-D solution of DMA salt in water to a 100 mL volumetric flask. To the flask was added 3.00 g of propylene glycol and the liquid was blended by shaking the flask by hand until the contents were uniform. Next, a solution of 24.52 g of 48.95 wt% ae DMA salt of glyphosate in water was added to the volumetric flask. The volumetric flask was shaken again by hand until the contents were blended and homogeneous. Next, a tertiary amine oxide surfactant (3.60 g C / 12; 6.00 g for all other samples) and the flask was shaken manually until the contents were blended and homogeneous. Finally, add deionized water and fill the volumetric flask to the 100 mL mark. The samples were ...

Embodiment 3

[0059] Embodiment 3: containing dicamba diglycol ammonium (DGA) salt, glyphosate isopropyl ammonium (IPA) salt and tertiary In-tank mix spray solution of amine oxide surfactants

[0060] A tank mix spray solution containing dicamba diglycol ammonium (DGA) salt, glyphosate isopropyl ammonium (IPA) salt and tertiary amine oxide surfactant was prepared as follows. First add 276.73 mL of deionized water to the sample container, then add 4.56 g of 30% w / w LO solution and mix. Next, add 11.22mL Herbicide concentrate (commercially available 4 pounds of acid equivalent / gallon (lb ae / gal) glyphosate IPA salt solution obtained from Dow AgroSciences, LLC) and 7.49 mL Herbicide concentrate (commercially available 4 lb ae / gal solution of dicamba DGA salt obtained from BASF Corporation (Florham Park, NJ)), then the samples were shaken manually until the mixture was homogenous (<1 minute). The samples were used in Example 1 The spray was carried out by the same method and technique...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com