Automatic panel four-edge trimming saw

An edge sawing machine and four-sided technology, which is applied in the field of plate four-sided automatic edge sawing machine, can solve the problems of inability to flatten, complex electrical circuit, high manufacturing cost, etc., and achieve the effect of facilitating precise processing and manufacturing, improving processing efficiency, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

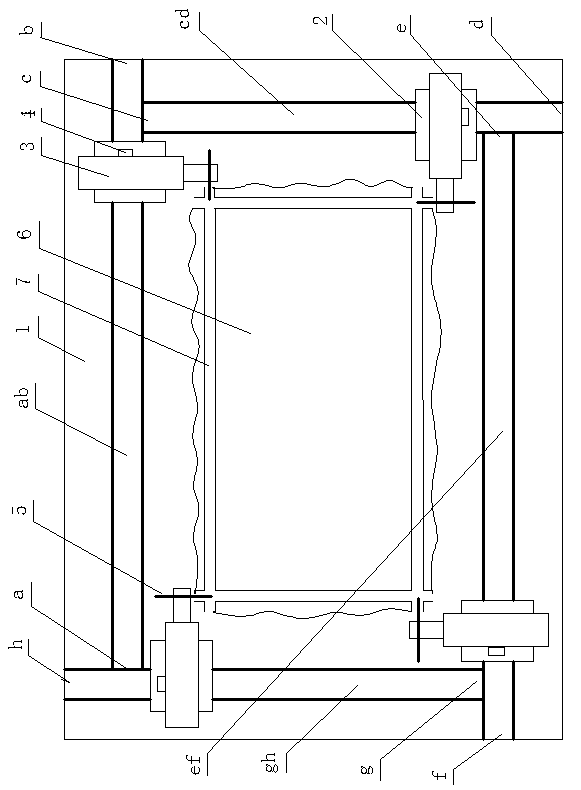

[0026] Such as figure 1 As shown, a four-sided automatic edge sawing machine for plates includes a guide rail seat, and four sets of linear guide rails are fixed on the guide rail seat 1; that is, the first group of vertical linear guide rails ab, the second longitudinal group of linear guide rails ef, and the first group of horizontal linear guide rails. The linear guide rail cd and the second group of horizontal linear guide rails gh form a rectangular linear guide rail frame.

[0027] One end a of the first group of longitudinal linear guide rails ab is set between the two ends of the second group of horizontal linear guide rails gh, on the inner side of the linear guide rail frame, and close to one end h; one end c of the first group of horizontal linear guide rails cd is set at the first group of longitudinal linear guide rails Between the two ends of the linear guide rail ab, on the inner side of the linear guide rail frame, near one end b; the first group of longitudin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com