single point needle valve

A needle valve and single-point technology, which is applied in the field of single-point needle valves, can solve problems such as unadjustable and prone to errors, and achieve the effect of avoiding multiple modifications and saving modification time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] According to the claims of the present invention and the content disclosed in the summary of the invention, the technical solution of the present invention is specifically as follows:

[0028] In the prior art, the processing size of the single-point needle valve has been fixed and fixed, and it cannot be adjusted, which is prone to error problems. The previous single-point needle valve had to undergo mold repair or modify the valve needle before completing the operation, and it required multiple data changes to complete the operation. Meet reasonable requirements.

[0029] The utility model discloses a single-point needle valve to solve the above problems.

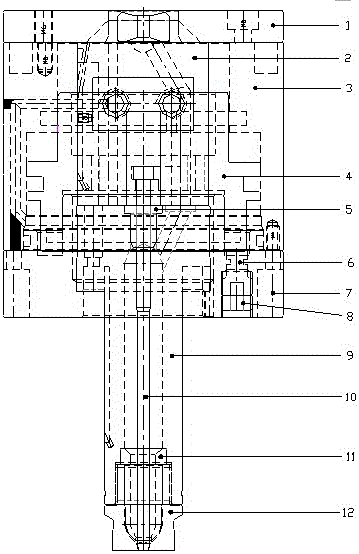

[0030] figure 1 It is a schematic diagram of the structure of the single-point needle valve of the present invention, please refer to figure 1 , a single-point needle valve, including:

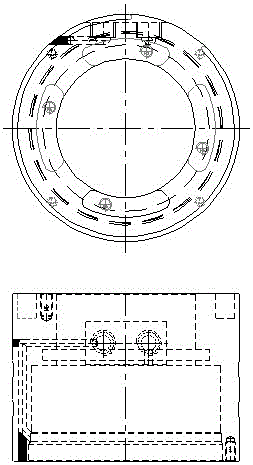

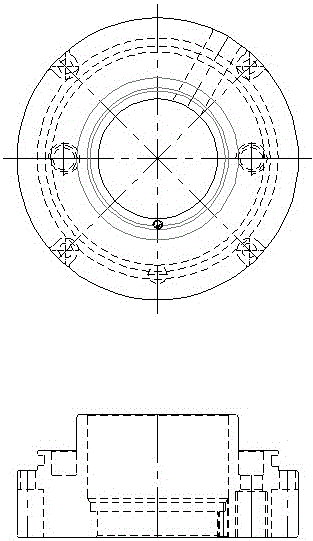

[0031] figure 2 It is a structural schematic diagram of the cylinder body of the single-point needle valve of the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com