Pressurizing and decompressing process for coal lock by utilizing byproduct carbon dioxide gas and coaling system

A carbon dioxide and secondary pressure relief technology, which is applied in the field of coal gasification, can solve the problems of effective product gas loss, gas flammability and explosion, and large equipment investment, so as to increase the coal loading load, overcome discontinuous and unstable coal addition, The effect of reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Embodiments of the present invention will now be described more fully with reference to the accompanying drawings. The following description is merely exemplary in nature and does not limit the invention, its application or uses.

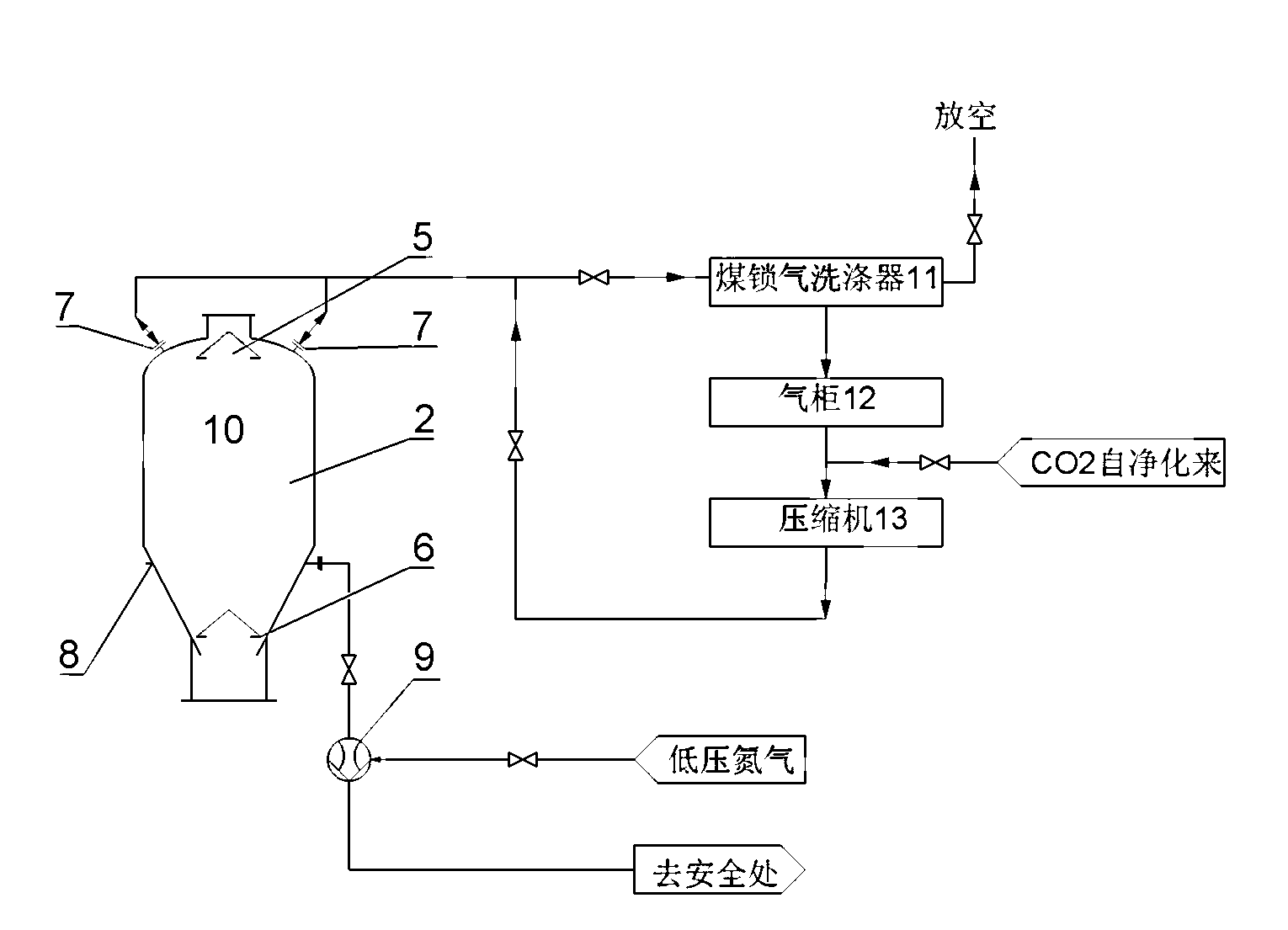

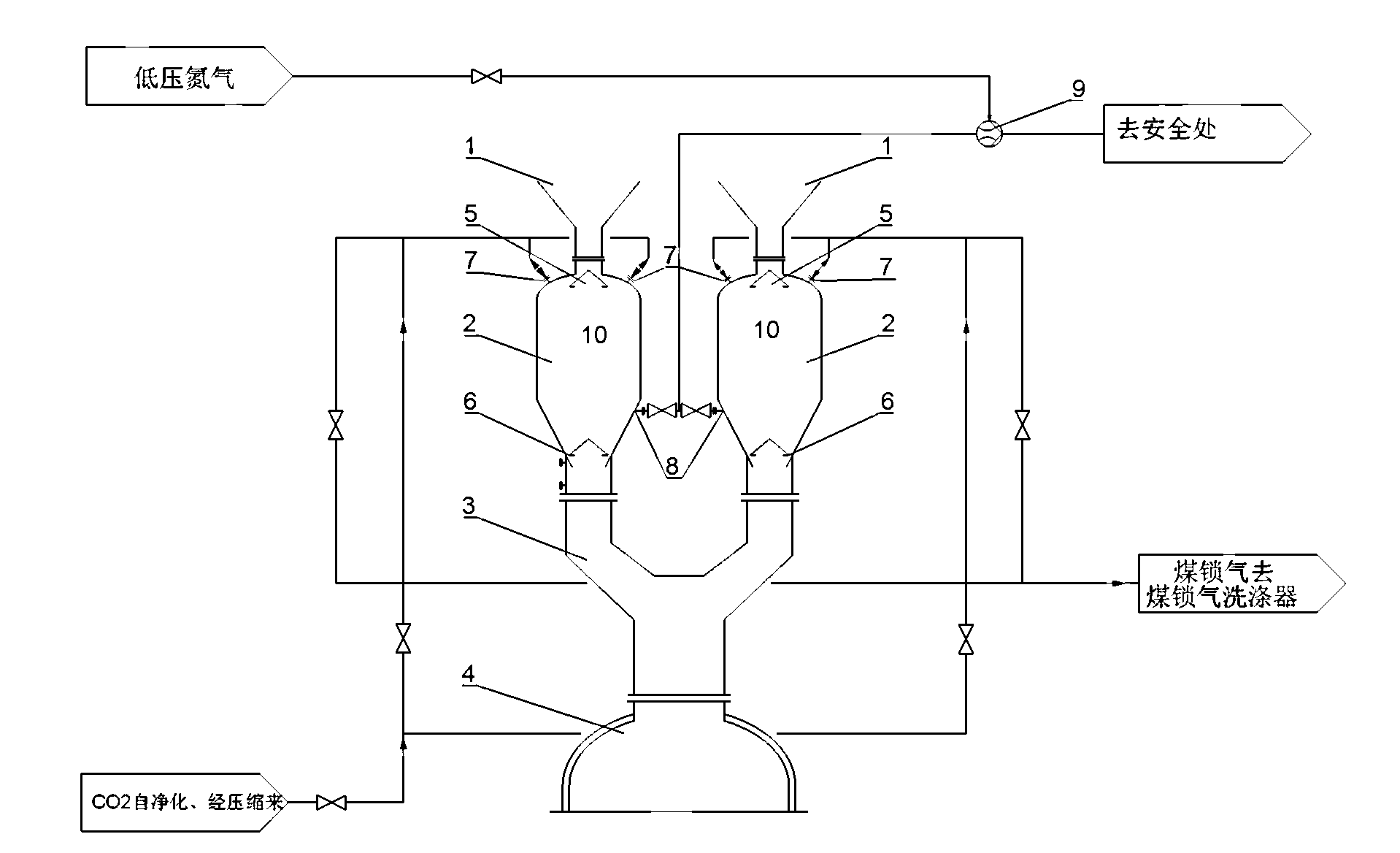

[0036] Referring to Figure 1, a preferred embodiment of the present invention is shown. According to the present invention, the slag gasification furnace coal feeding process system using by-product carbon dioxide waste gas for charging and releasing pressure includes a coal hopper 1 , a coal lock 2 , a transition bin 3 and a gasifier 4 . The coal lock 2 includes an upper cone valve 5, a coal lock main body 10, a lower cone valve 6, a pressure charging / primary pressure relief nozzle 7, and a secondary pressure relief nozzle 8. Wherein the pressure charging / primary pressure relief nozzle 7 means that the nozzle 7 is used for both pressure charging and primary pressure relief.

[0037]In a preferred embodiment of the present invention, the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com