Fitting support and opening roller with quick release lock

A card clothing machine, fast technology, applied in the direction of spinning machine, mechanical equipment, free-end spinning machine, etc., can solve the problems of looseness, small axial holding force, impure spinning thread, etc., to achieve firm fixation, installation and Quick effect of disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

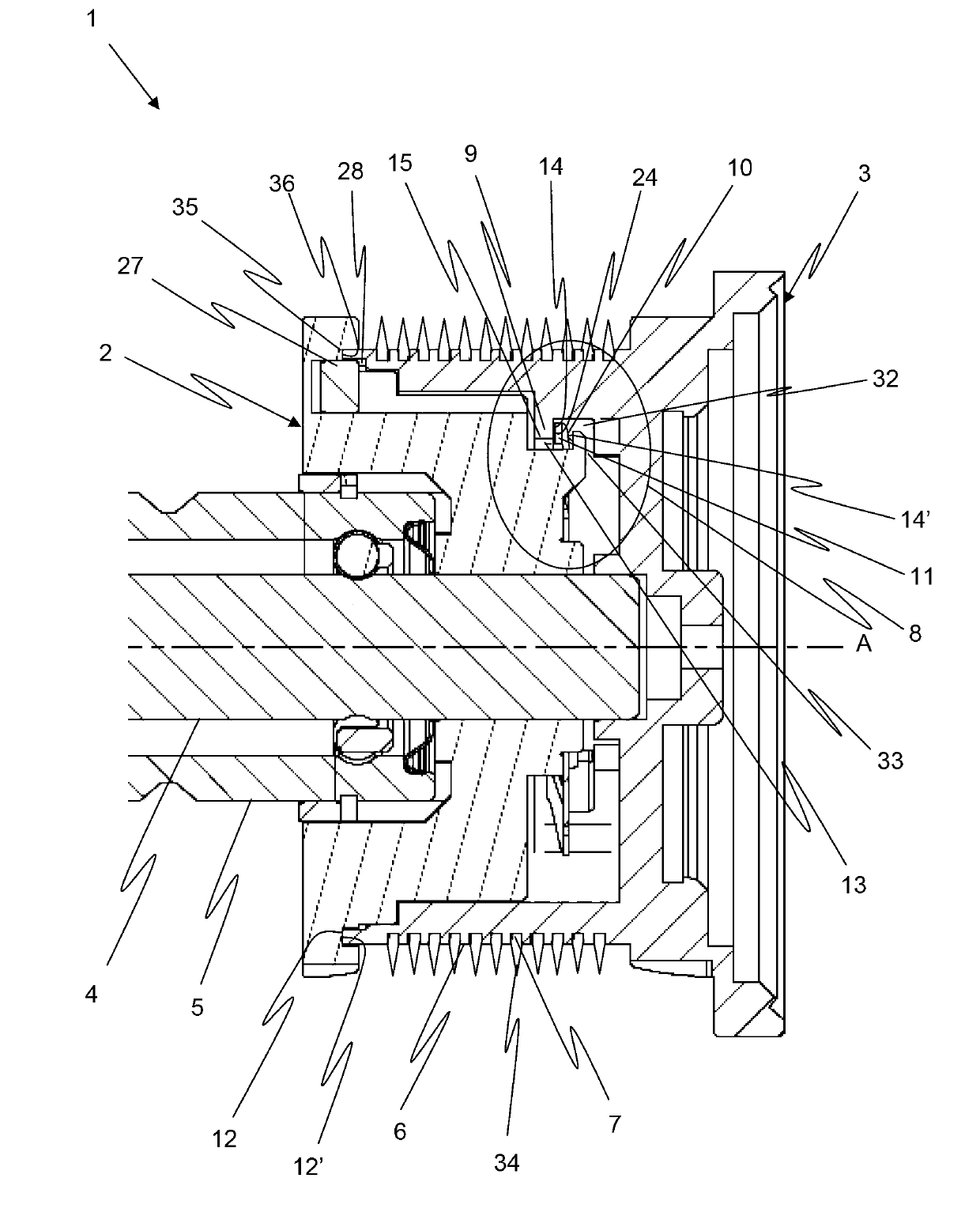

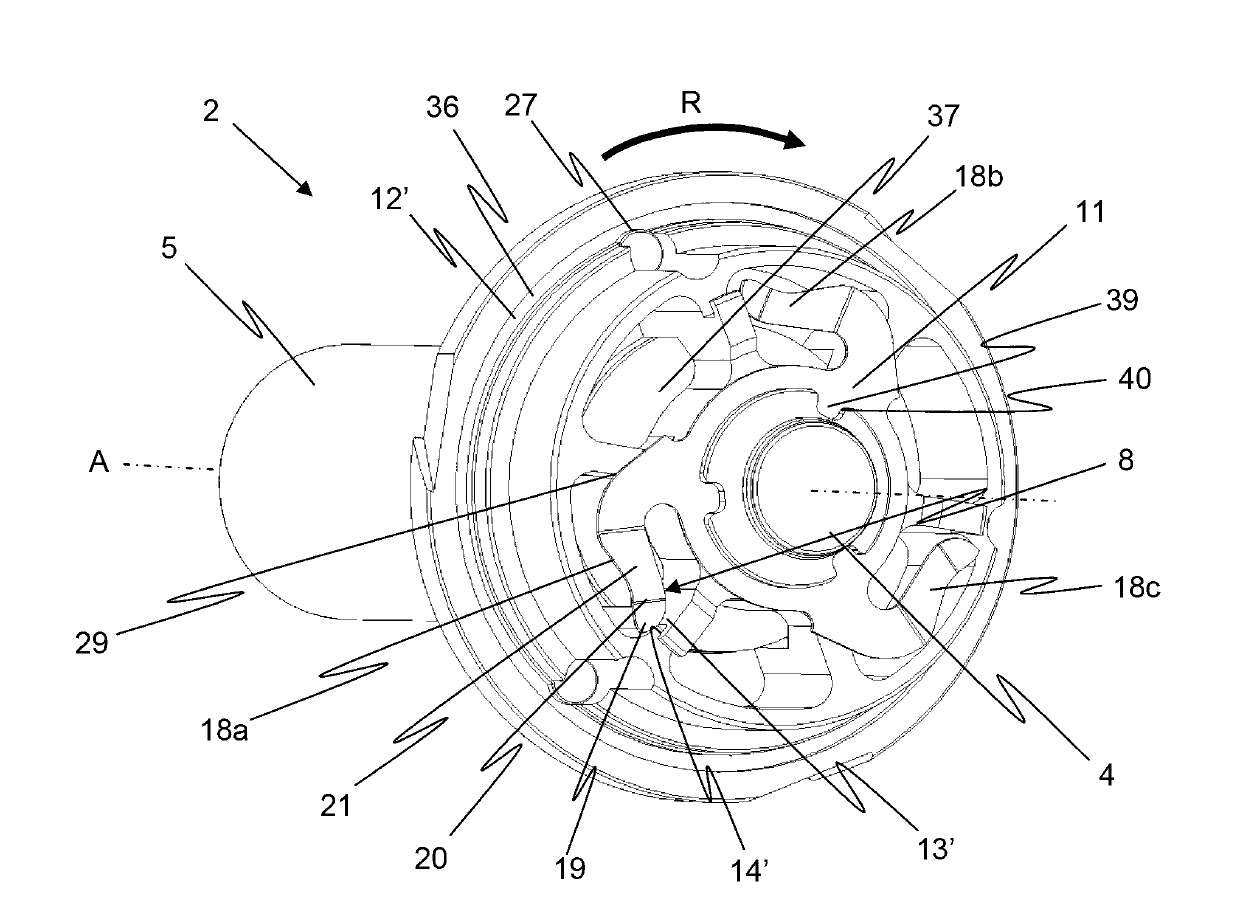

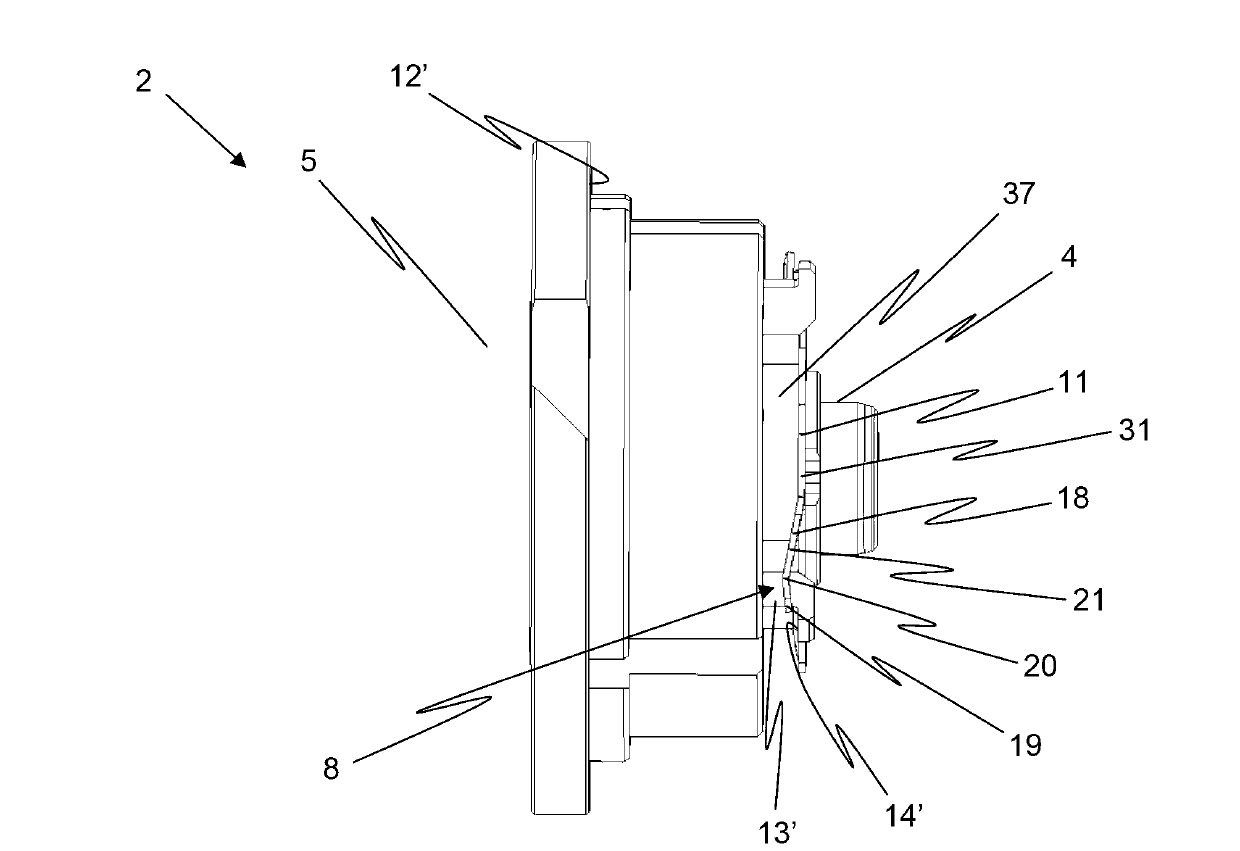

[0044] figure 1 Shown is an opening roll 1 for an open-end spinning machine, which has a basic body 2 and a clothing frame 3 . The opening roller 1 is centrally fixed on the drive shaft 4 of the open-end spinning machine through the base body 2, and the open-end spinning machine is figure 1 is not shown in . The clothing frame 3 is also positioned centrally on the drive shaft 4 . The drive shaft 4 is installed in the housing 5 and is rotatable. The clothing frame 3 has on its periphery 6 a helical clothing recess 7 in which a clothing 34 is accommodated for opening the fiber coil.

[0045] The basic body 2 and the clothing frame 3 are detachably connected to one another by means of a rotary lock 8 . The swivel lock 8 is designed in such a way that it can quickly and easily mount the clothing frame 3 on the base body 2 or remove it from the base body 2 while bearing very high forces in the axial direction. The swivel lock 8 is therefore designed such that the clothing fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com