Device and method for detecting brake performance of automobile

A technology of automobile braking and performance, which is applied in the direction of measuring devices, vehicle testing, machine/structural component testing, etc., can solve the problems of detection process limitations, time and money spent, road test danger, etc., to facilitate operation, Ease of use and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

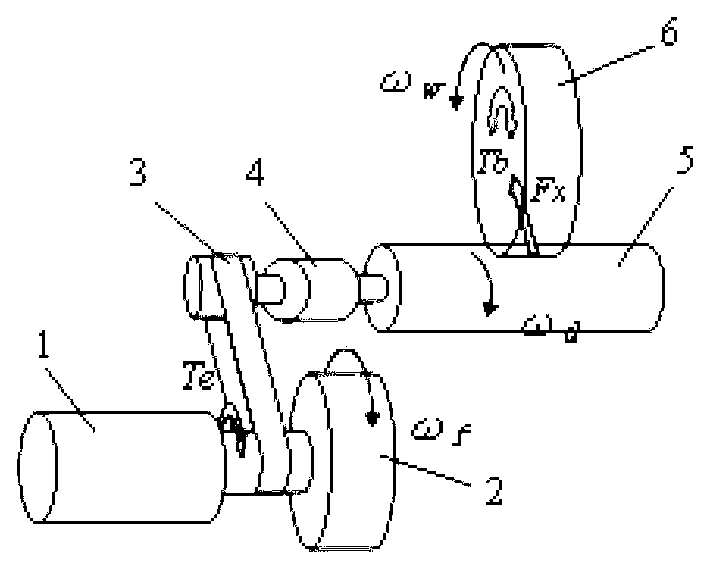

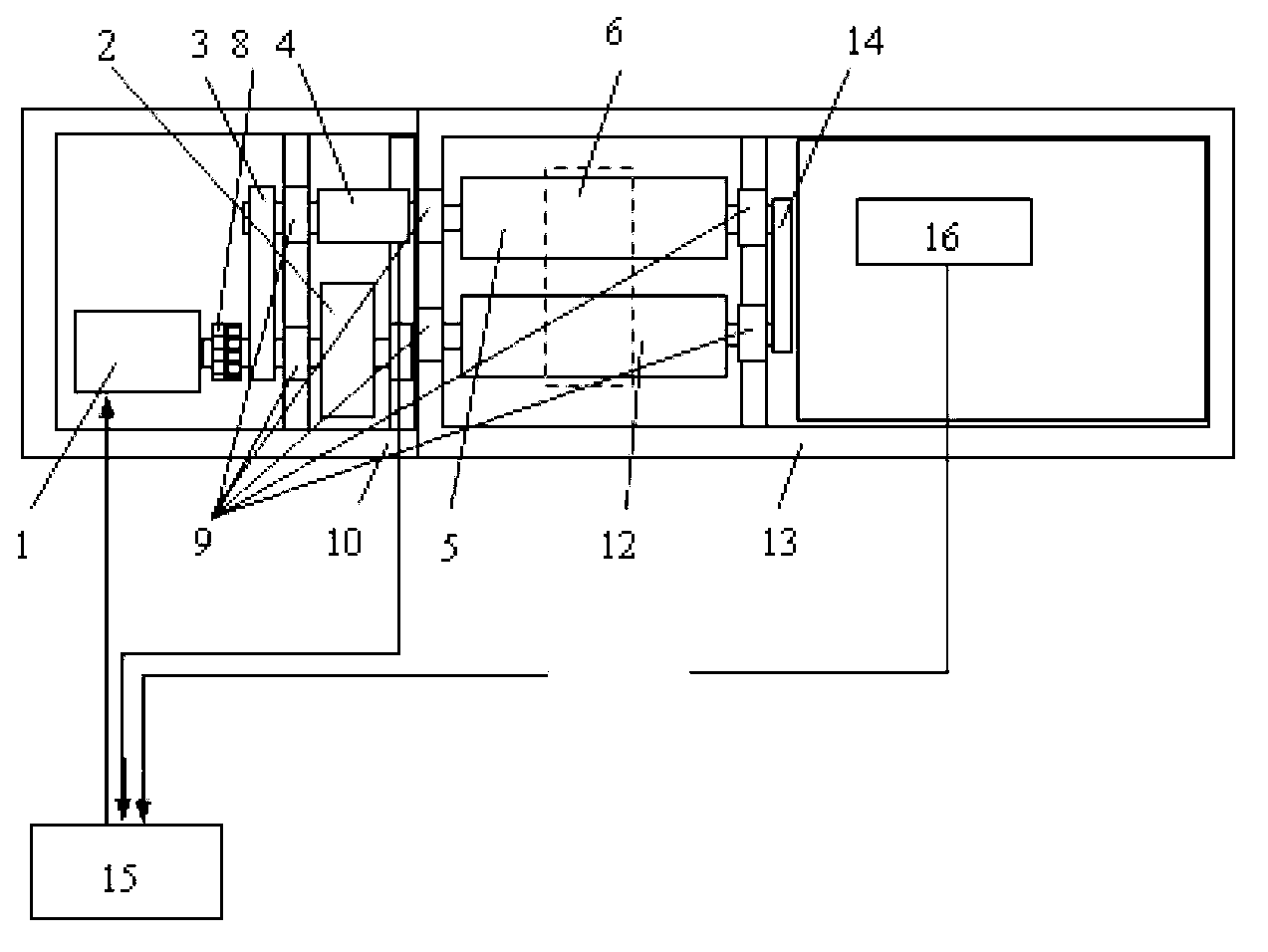

[0036] Such as figure 1 As shown, the present embodiment provides a device for detecting the braking performance of an automobile, including an inertial mechanism, a driving mechanism for driving the inertial mechanism to rotate, a first rolling mechanism in frictional contact with the wheel 6, a first rotational speed detection unit, and a first rotation speed detection unit. Two rotational speed detection units; wherein, the first rolling mechanism is connected to the inertial mechanism through a first synchronous transmission mechanism, the first rotational speed detection unit is used to detect the rotational speed of the first rolling mechanism, and the second rotational speed The detection unit is used to detect the rotation speed of the wheel 6 . Among them, the inertial mechanism specifically adopts the flywheel 2, the driving mechanism specifically adopts the motor 1, the first rolling mechanism specifically adopts the first drum 5, the first rotational speed detectio...

Embodiment 2

[0051] This embodiment provides a method for detecting vehicle braking performance using the above-mentioned device, including the following steps:

[0052] (1) Make the driving mechanism drive the inertial mechanism to move, the inertial mechanism drives the first rolling mechanism to rotate through the first synchronous transmission mechanism, and the first rolling mechanism drives the wheel 6 to roll through frictional contact. Wherein, the inertia mechanism specifically adopts the flywheel 2 , the driving mechanism specifically adopts the motor 1 , the first rolling mechanism specifically adopts the first drum 5 , and the first synchronous transmission mechanism specifically adopts the first belt 3 . Wherein, the total moment of inertia of the first drum 5 , the flywheel 2 and the motor 1 is the same as the moment of inertia obtained by converting the mass of the translational load of the wheel 6 .

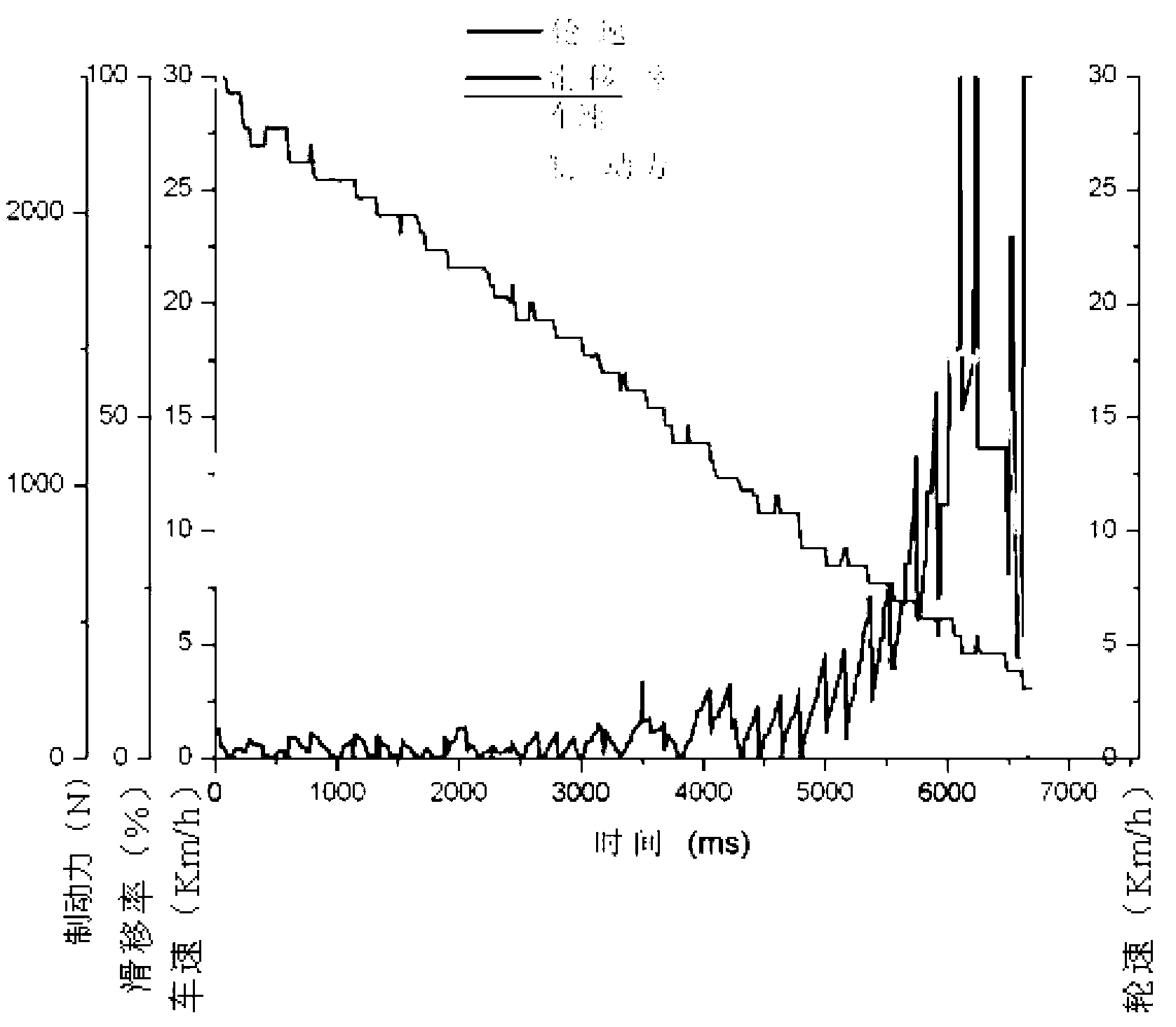

[0053] (2) In the device for detecting the braking performance of an auto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com