Method for controlling pressure of propellant storage box

A propellant storage tank and pressure technology, which is applied in the direction of fluid pressure control, non-electric variable control, control/regulation system, etc., can solve the problems that cannot meet the requirements of the test task book

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0101] A method of controlling the pressure of a propellant tank comprising the steps of:

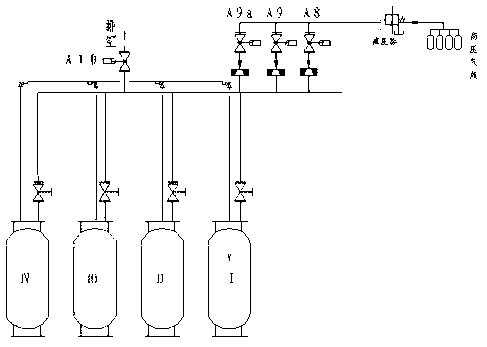

[0102] 1] Connect the propellant pressurization system;

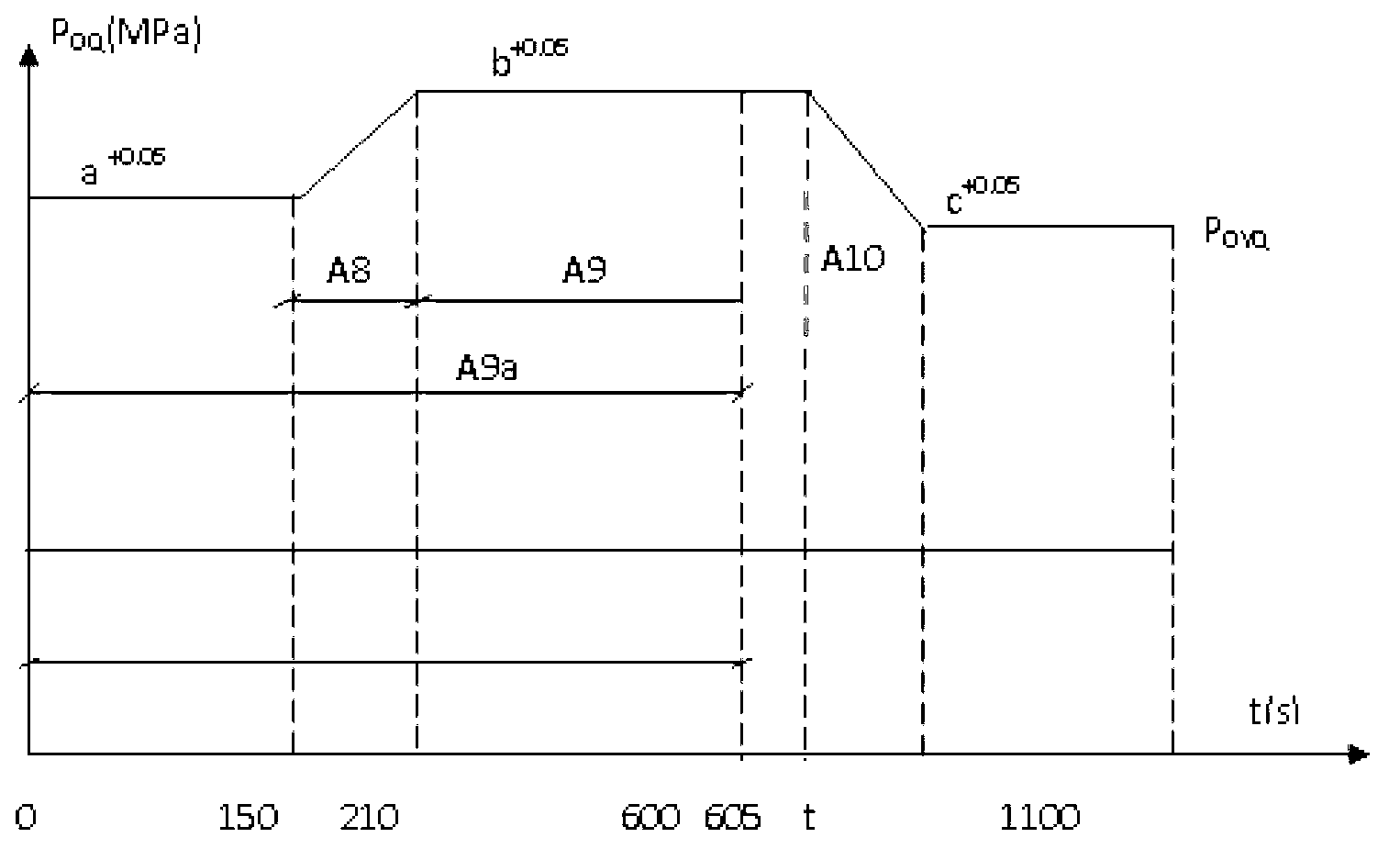

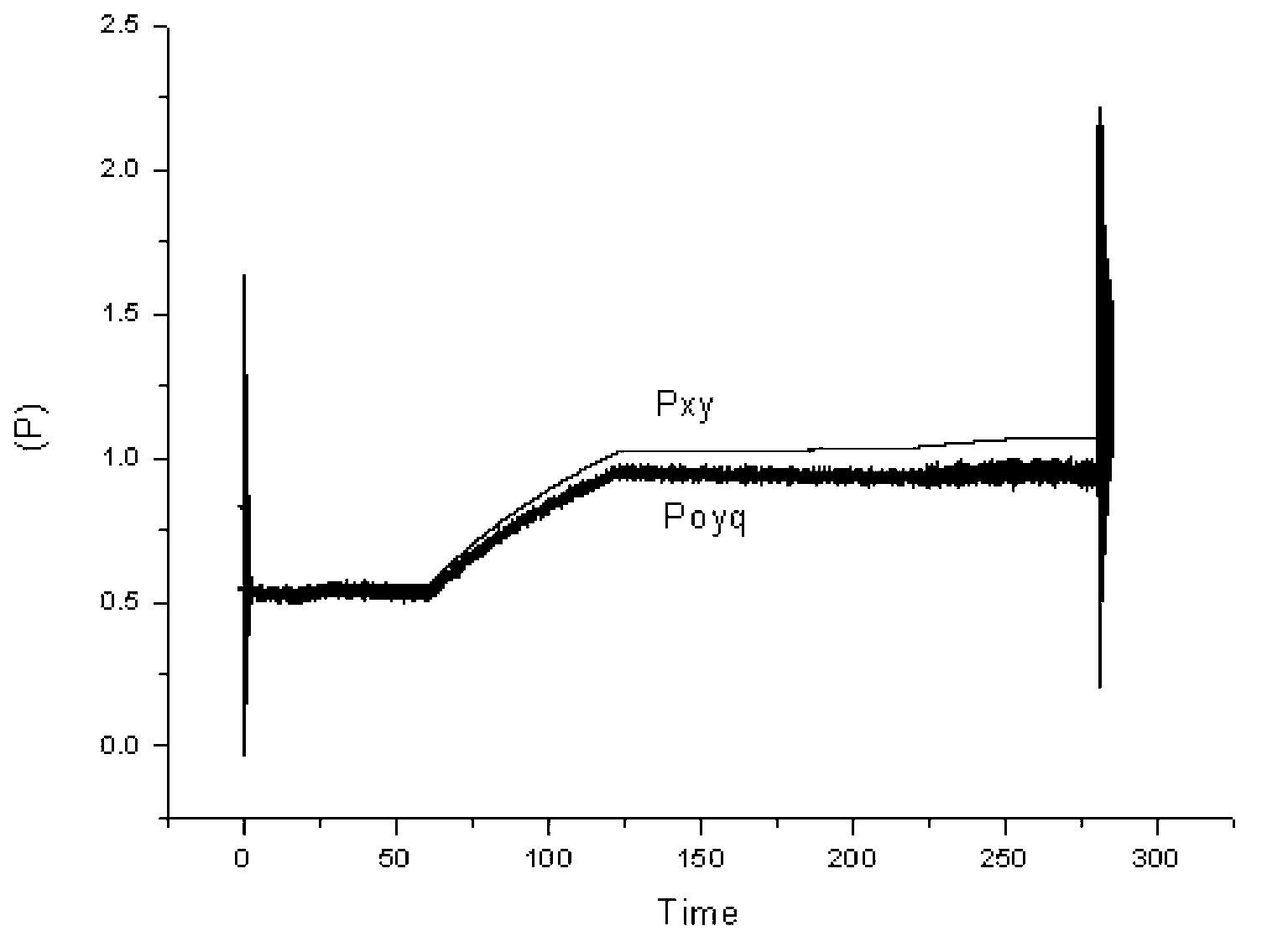

[0103] 2] Start the control center, and realize the control of the pump inlet pressure according to the pump inlet pressure curve required by the user (mission statement): the pump inlet pressure curve includes the pre-stabilization section, boost section, overload section and deflation section connected in sequence: as figure 2 As shown in the mission statement, the requirements of the task book are: the inlet pressure is stable at a+0.05MPa in 0~150 seconds, we call this period of time the pre-stabilization period; the inlet pressure increases from aMPa to bMPa in 150~210 seconds, we call this period of time boost section; 210 seconds to 600 seconds, the inlet pressure is kept at bMPa, we call this period of time overload; after 600 seconds, the main engine shuts down, and the inlet pressure needs to be reduced to cMPa, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com