A method for preparing se battery with segmented mask pattern

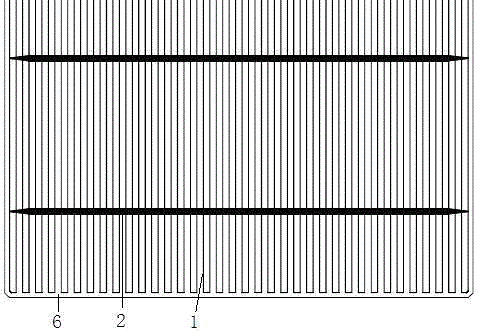

A mask pattern, segmented technology, applied in the manufacture of circuits, electrical components, final products, etc., can solve the problems of high cost and large consumption of SE etching mask slurry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

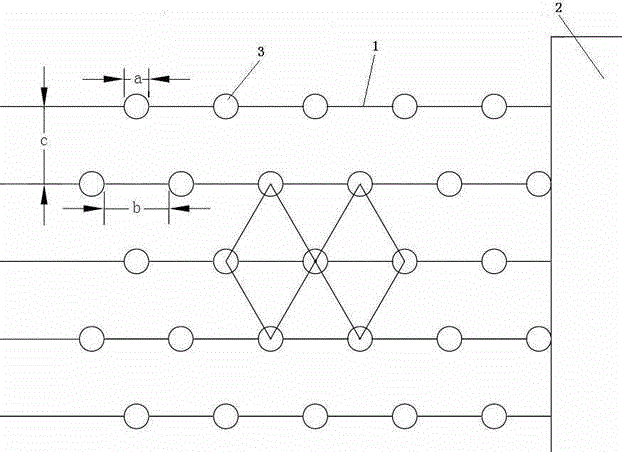

[0056] Such as figure 2 , the thin grid line 1 is divided into segmented fine grid lines composed of a:b=1:1 from the straight-through type, and each segmented SE mask paint coverage area adopts a rectangular shape, and the segmented SE mask paint coverage The distribution between the regions can be arranged in a regular hexagon, so that the electrons in all the emission regions can be absorbed within the shortest distance, that is, within the radius of an equal circle with the center of the segmented SE mask coating area as the center. Collected by fine grid electrodes connected to the paint coverage area of each segmented SE mask. This solution can reduce 50% of the SE etching mask fine grid line slurry consumption while ensuring the conversion efficiency.

Embodiment 2

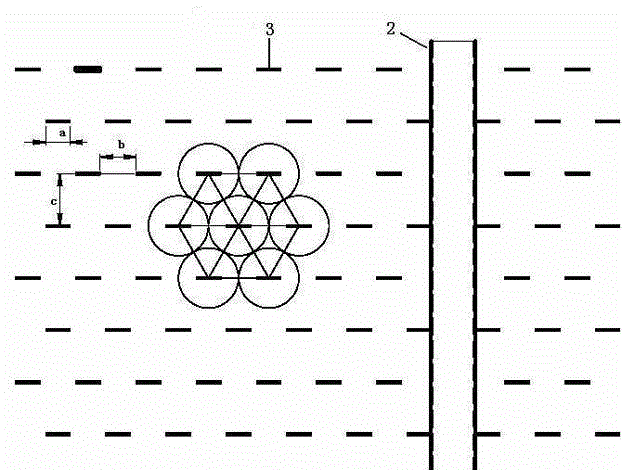

[0058] Such as image 3 , the thin grid lines are divided into segmental SE masking paint coverage areas composed of a:b=1:6.26 by straight-through type, each segment adopts a circular shape, and the distribution between segmental SE masking paint coverage areas can be Arranged in a regular hexagon, so that the electrons in all emission regions can be within the shortest distance, that is, less than or equal to the radius of the equal-diameter circle centered on the center of the segmented SE mask paint coverage area, by each segmented fine grid collected by wire electrodes. This solution can reduce 86.2% of the SE etching mask fine grid line slurry consumption while ensuring the conversion efficiency.

Embodiment 3

[0060] Such as Figure 4 , the thin grid line SE mask paste pattern is divided into a segmented SE mask coating area composed of a:b=3:1 by a straight-through type, and each segment adopts a bamboo-shaped shape, and the segmented SE mask coating The distribution between the coverage areas can be arranged in a regular hexagon, so that the electrons in all the emission areas can be separated by each segment within the shortest distance, that is, within the radius of the equidiameter circle centered on the center of the fine grid line. Collected by fine-grid electrodes connected to the SE mask paint footprint. This solution can reduce 33.3% of the SE etching mask fine grid line slurry consumption while ensuring the conversion efficiency.

[0061] In each of the above embodiments, a is the length of the segmented SE mask coating area, and b is the distance between two adjacent segmented SE mask coating areas. It can be seen that the SE slurry saving effect of Example 2 is the bes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com