Electro-acoustic transducer and manufacturing method thereof

An electro-acoustic transducer and manufacturing method technology, applied in the direction of sensors, electrical components, etc., capable of solving problems such as danger of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

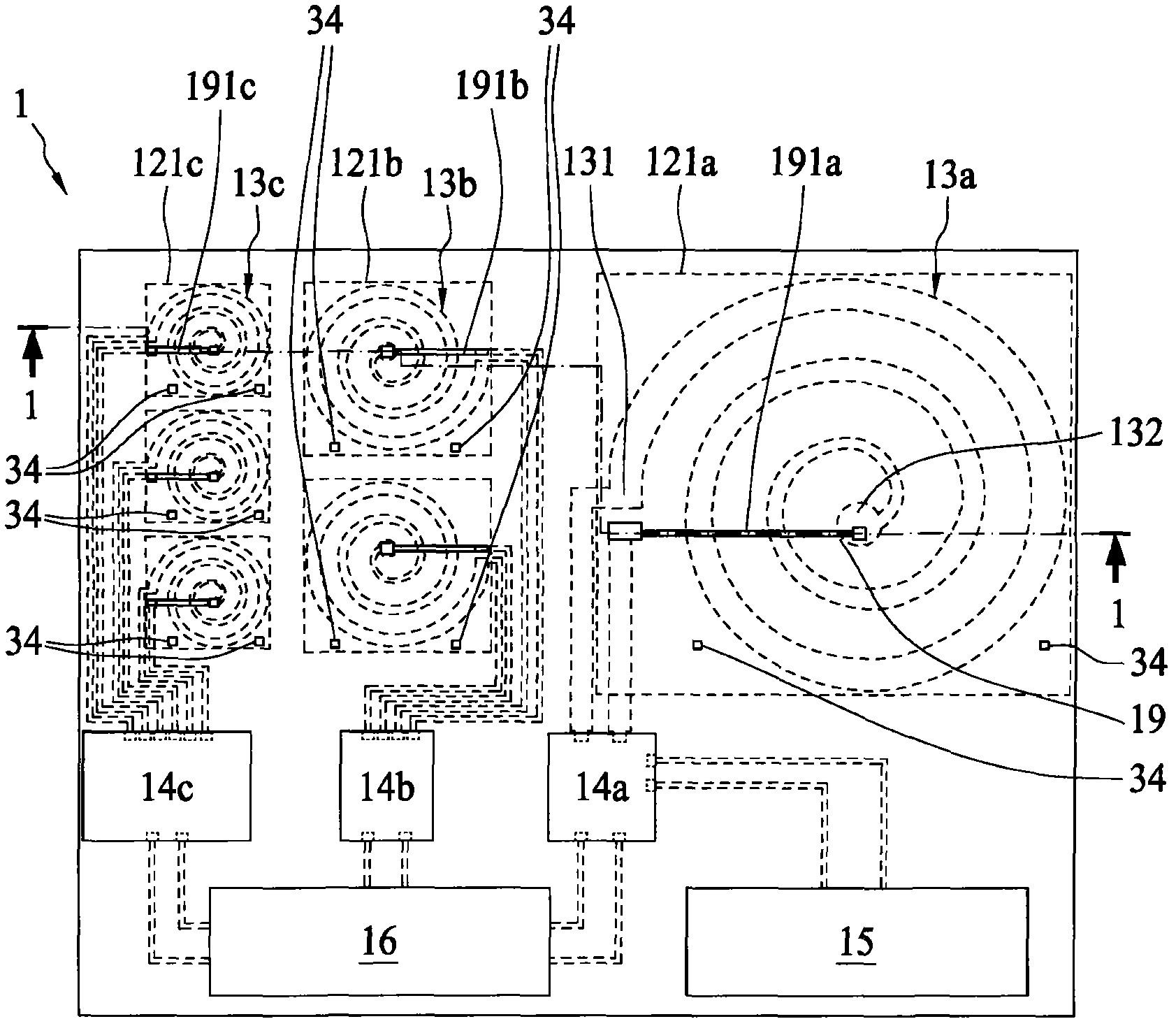

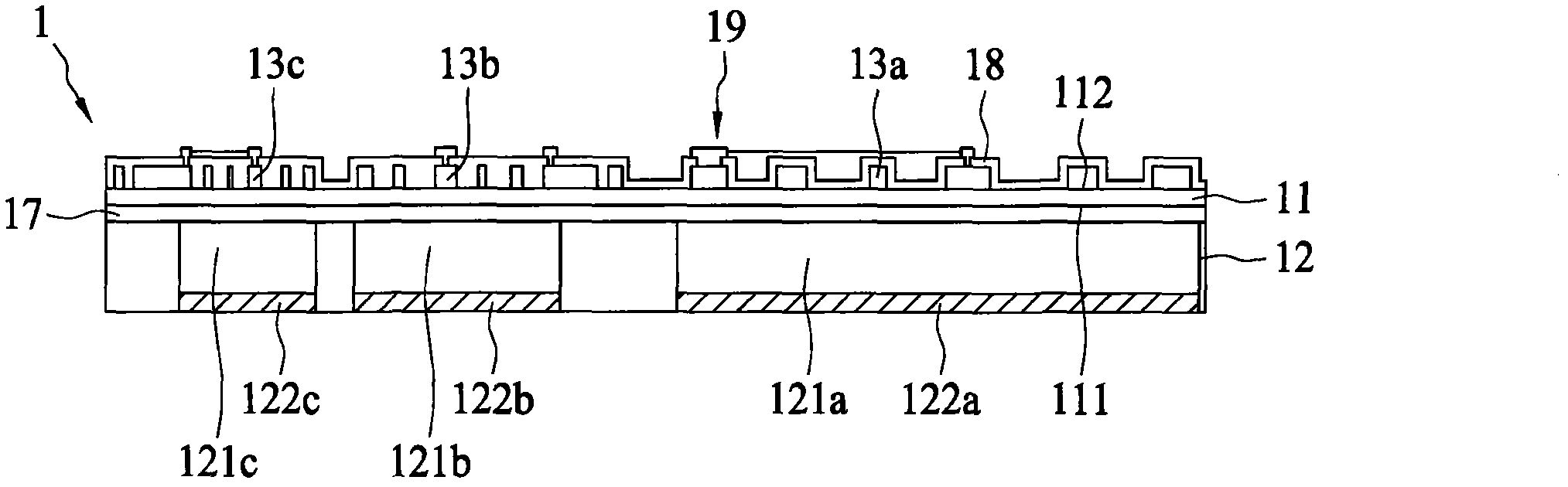

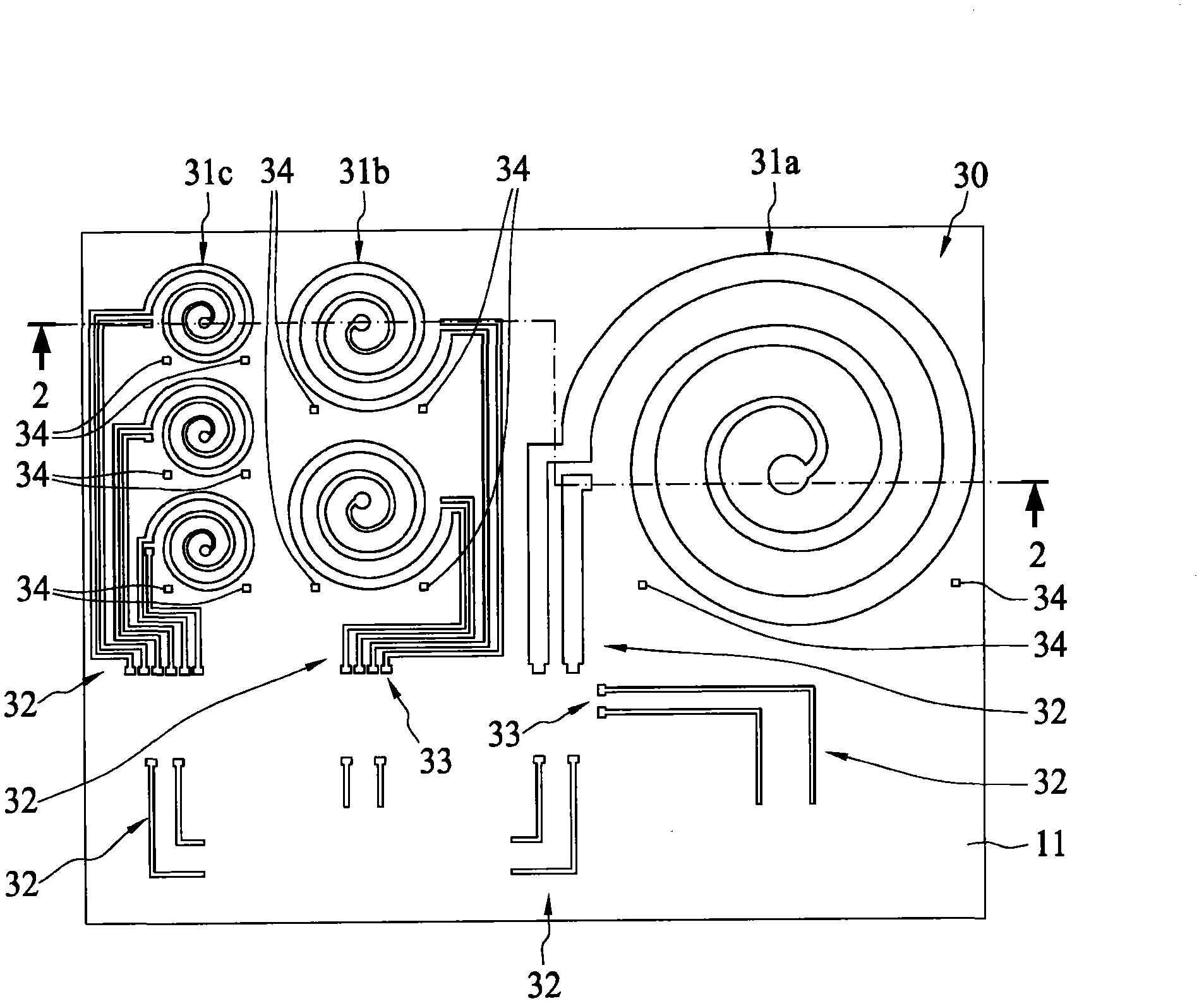

[0047] figure 1 A schematic top view of an electro-acoustic transducer 1 according to an embodiment of the present invention is shown. figure 2 for along figure 1 Sectional view of the 1-1 section line. refer to figure 1 and figure 2 As shown, the electro-acoustic transducer 1 may include an insulating flexible substrate 11, a base 12, and at least one magnetic field generator (13a, 13b or 13c). The base 12 may have at least one cavity (121a, 121b or 121c) and at least one magnetic portion (122a, 122b or 122c), wherein at least one magnetic portion (122a, 122b or 122c) is correspondingly formed in the at least one cavity (121a, 121b or under 121c), as in figure 1 shown. The insulating flexible substrate 11 is disposed on the base 12, covering at least one cavity (121a, 121b or 121c), so that the insulating flexible substrate 11 can be supported, and at least one cavity (121a, 121b or 121c), there can be a space to generate vibration. At least one magnetic field gener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com