Electronic ballast

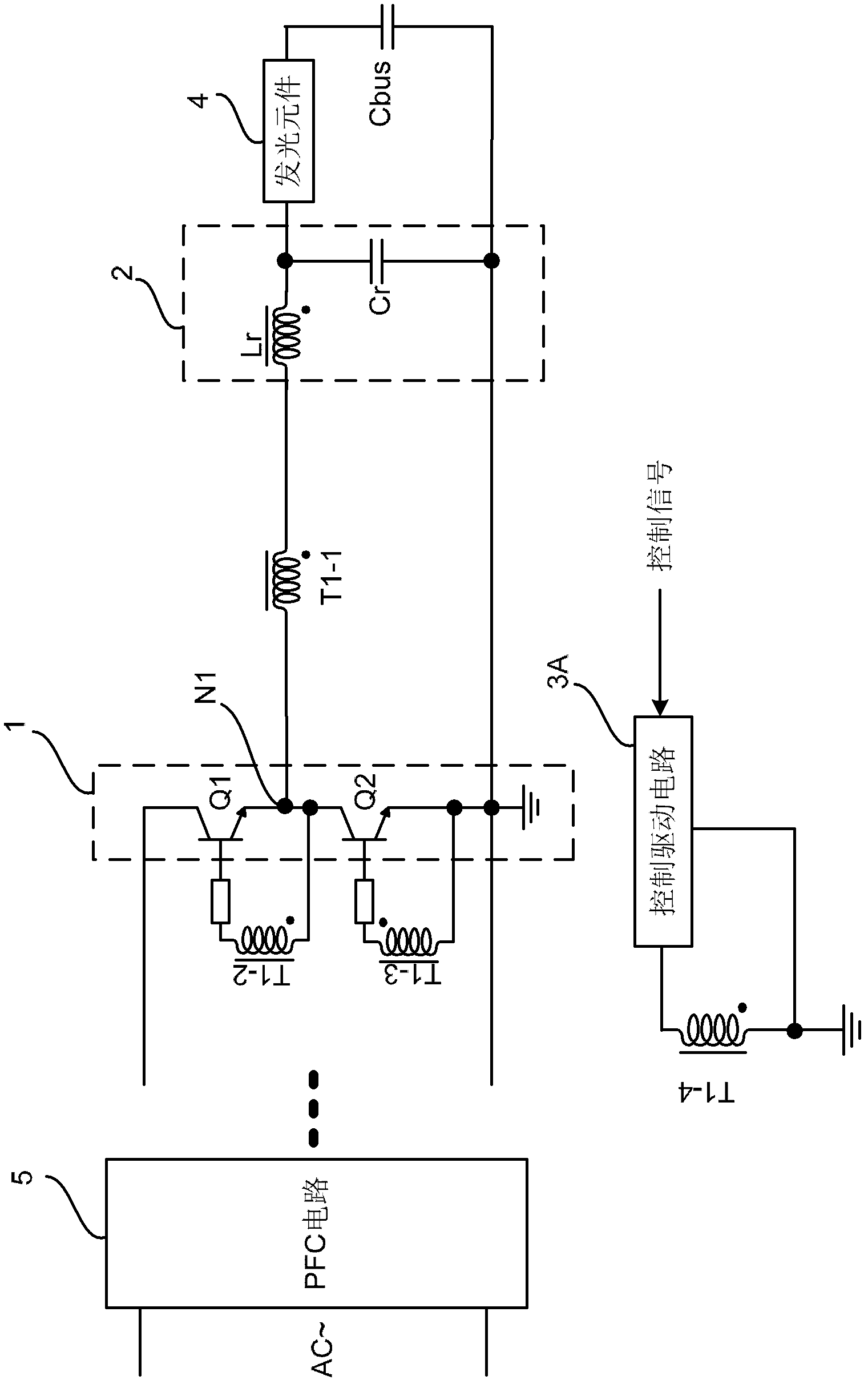

An electronic ballast and resistance technology, applied in electric light sources, electrical components, lighting devices, etc., can solve problems such as difficulty in controlling the working current or power of light-emitting elements, and difficulty in controlling the output voltage and output current of self-excited electronic ballasts. To achieve the effect of controlling the operating frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

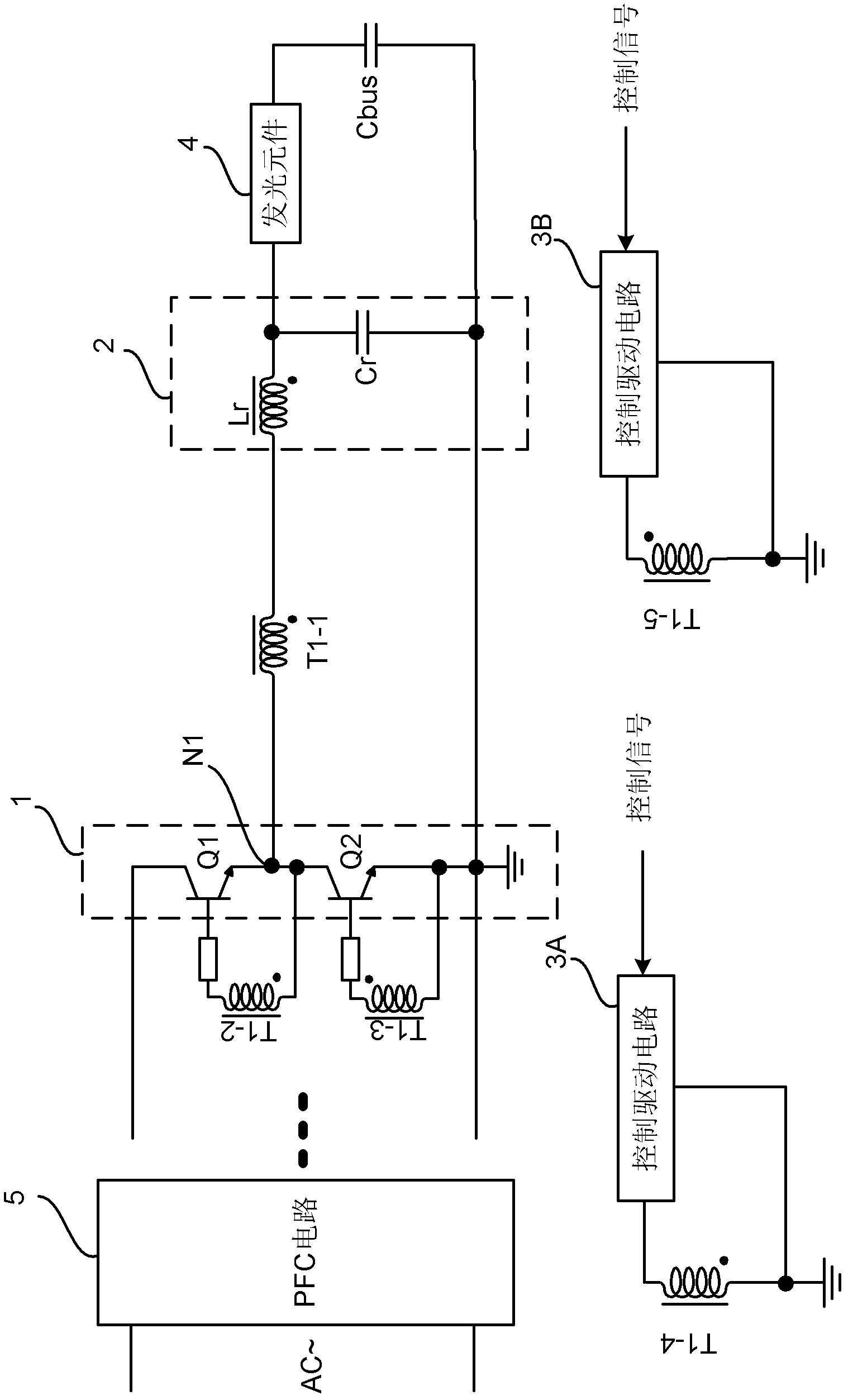

Embodiment 2

[0038] In the second embodiment, by setting the induction windings T1-4 and T1-5, the on-times of the transistors Q1 and Q2 are both shortened, so that the adjustment range of the operating frequency of the electronic ballast can be higher than that of the first embodiment. Embodiment 2 can be adopted when the operating frequency range of the electronic ballast is required to be variable. Compared with the first embodiment, the second embodiment can realize more in-depth control of the electronic ballast, and can achieve a large degree of control over the operating current of the light-emitting element.

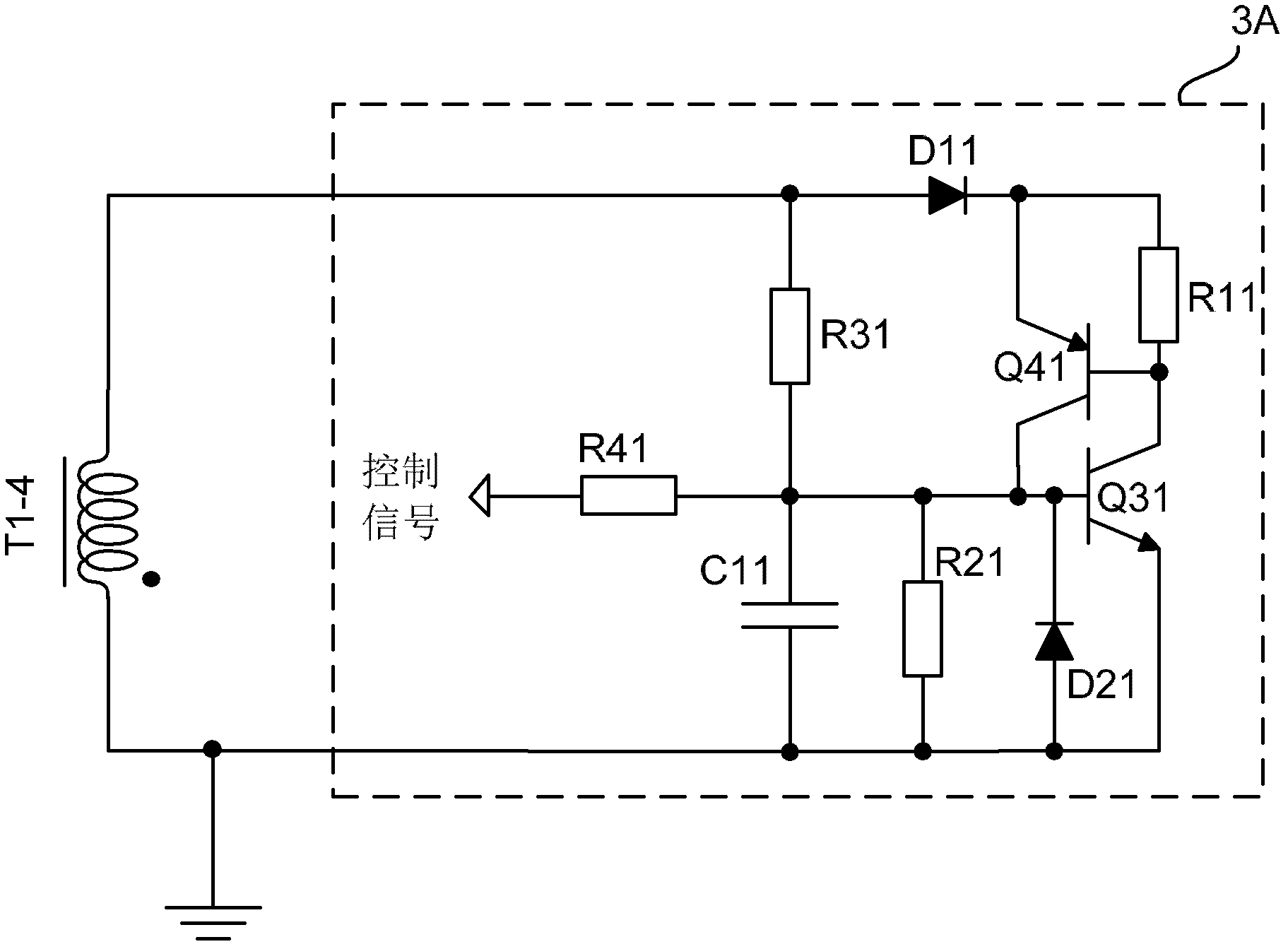

[0039] In an embodiment of the present invention, the control drive circuit 3A or 3B may be a circuit capable of controlling the voltage across the induction winding. For example, it can be a clamping circuit, which can receive a control signal and pull down the voltage across the induction winding during operation so that the control winding coupled with the induction windin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com