E-shaped rack riveting mould for roller bearing

A roller bearing, riveting technology, applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., to achieve the effect of low working noise, simple operation, and improved quality of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

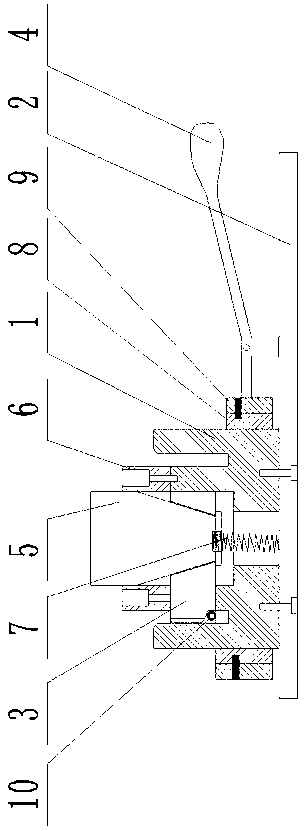

[0012] Such as figure 1 As shown, the roller bearing E-frame riveting die of the present invention includes a main die body 1, a bottom plate 2 and a punch 5, the main die body 1 is arranged on the bottom plate 2, and an external expansion slider 3 is arranged inside the main die body 1 , the outer shape of the outer expansion slider 3 is adapted to the inner shape of the E-shaped cage of the roller bearing, and the outer side of the outer expansion slider 3 is provided with a first spring 10 for resetting the outer expansion slider 3, and the outer expansion slider 3 There is a tapered through hole in the vertical direction, the upper part of the punch 5 is cylindrical, the lower part of the punch 5 is conical, and the lower part of the punch 5 matches the tapered through hole of the outwardly expanding slider 3. The guide sleeve 6 that guides the punch 5 to move up and down is arranged on the upper part of the main mold body 1, and the second spring 7 used to reset the punch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com