Low-carbon high-performance tunnel shotcrete series

A technology of sprayed concrete and tunnel spraying, which is applied in the field of building materials, can solve the problems of concrete corrosion, uneconomical, difficult mix ratio, etc., achieve the effect of improving compactness and mechanical properties, improving structural durability, and reducing operating intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

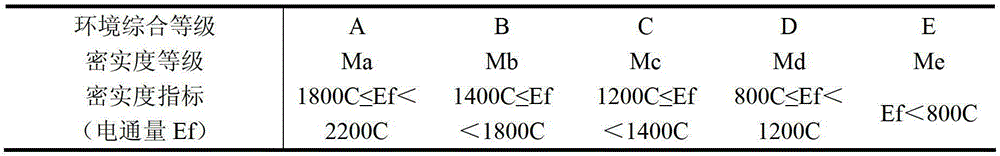

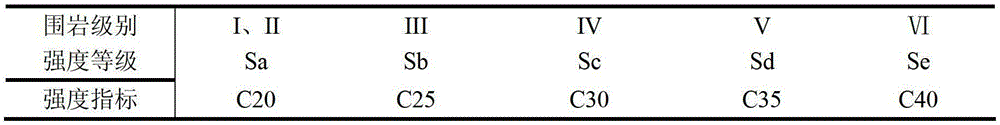

[0030] The low-carbon high-performance tunnel shotcrete of the present invention can respectively reach the strength grades of C20, C25, C30, C35, and C40, and meet the service life requirements of tunnel structures under different environmental types and different surrounding rock levels. Specific embodiments are given below.

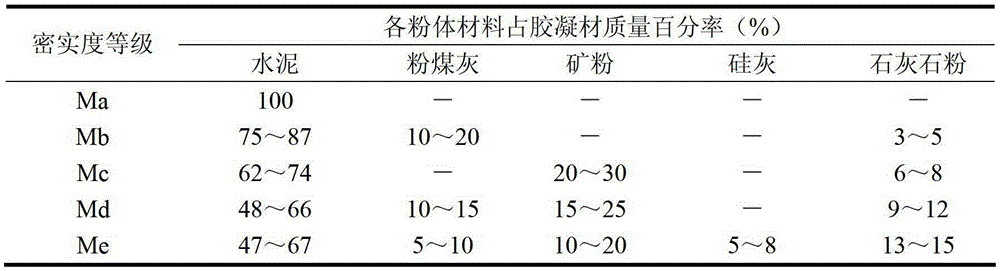

[0031] 1. Composite cementitious material can be realized through distribution station mode or mixing station mode. The specific method is to firstly grind the cement, fly ash, mineral powder and limestone powder in the composite cementitious material to the specified fineness, and make Then, according to the structural performance requirements of the tunnel, the cementitious material components are determined and formulated according to the designed cementitious material formula ratio to generate high-quality composite cementitious materials.

[0032] For high-performance concrete with complex components, the composite cementitious materials required ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com