Welding horizontal sleeve type lattice column

A lattice column and horizontal technology, which is applied in the direction of building structure, building structure support, building structure support, etc., can solve the problems of insufficient personnel construction and passing, many rods, heavy weight, etc., and achieves easy quality control and application Wide-ranging, lightweight effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

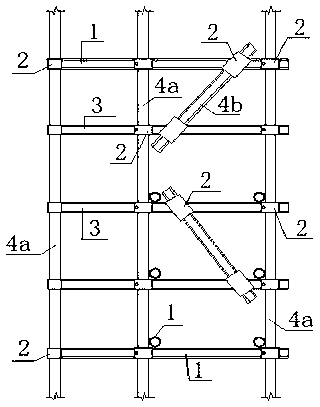

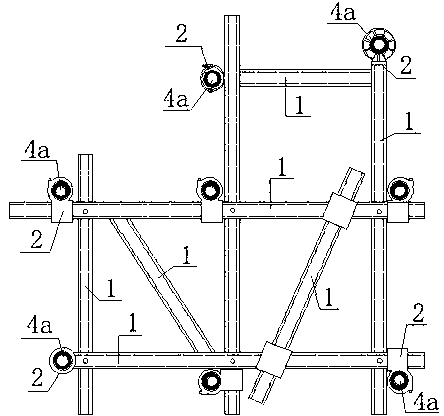

[0037] Example 1: See Figure 8 with Picture 9 , For a certain building structural concrete project, the formwork support under the girder adopts welded horizontal sleeved lattice columns. The cross section of the beam 8 is 500×1400 mm. In the same plane, each welded horizontal sleeve 3 is welded at the intersection with a φ48.3×3.6mm round steel pipe. 2 vertical horizontal rods, 4 horizontal horizontal rods, and welded pipe clamps on the vertical horizontal rods are used as connecting pieces 2. The welded horizontal sleeve 3 is connected to the circular steel pipe vertical rod 4a through the connecting piece 2 to form a welded horizontal sleeve type lattice column. The vertical and horizontal spacing of the uprights 4a is 400×400 mm, and the spacing of the welded horizontal sleeves 3 of the lattice column in the height direction is 600 mm. The lattice column upright 4a supports the main wooden keel under the girder template through the adjustable support 9. Other overall s...

Embodiment 2

[0038] Example 2: See Picture 10 , A double-row scaffolding project on the outer wall of a construction project. The floor plan of a building is 11, the horizontal distance of the scaffolding pole 4a is 1.05m, the vertical distance is 1.5m, the step distance is 1.8m, the distance from the center of the inner pole to the outer wall of the building is 0.3m, and the connecting wall is 2 steps and 2 spans. The scaffold adopts welded horizontal sleeve type lattice column. Each welding horizontal sleeve 3 is formed by welding round steel pipes of φ48.3×3.6mm. The welding horizontal sleeve 3 adopts different plane forms and welding methods at the straight section and the corner respectively. The straight line section is in the form of 1 span plus 2 sides picking out in the longitudinal direction, divided into 2 layers, the vertical horizontal rod is on the top, the horizontal horizontal rod is on the bottom, and the bolts and spacer blocks are welded at the overlapped place. The lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com