Continuous egg baking production machinery

A technology for producing machinery and egg products, applied in special commodity baking, baking, food science and other directions, can solve the problems affecting the baking quality of egg products, uneven color, low production efficiency, etc., to reduce labor costs and achieve uniform baking. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The content of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments of the description:

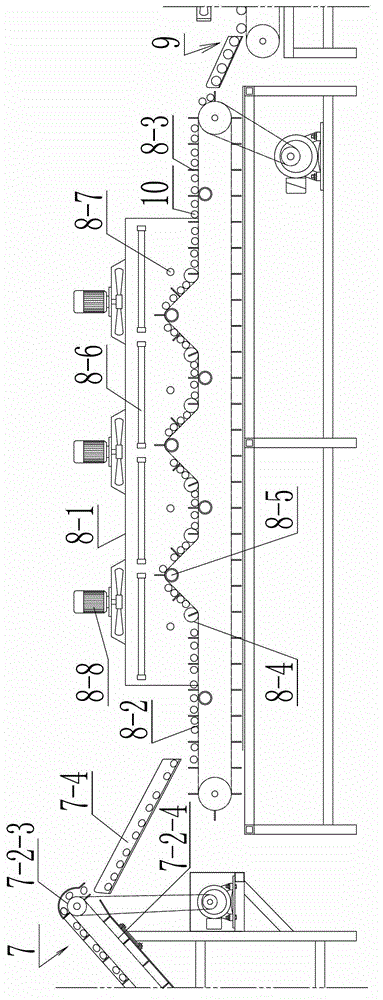

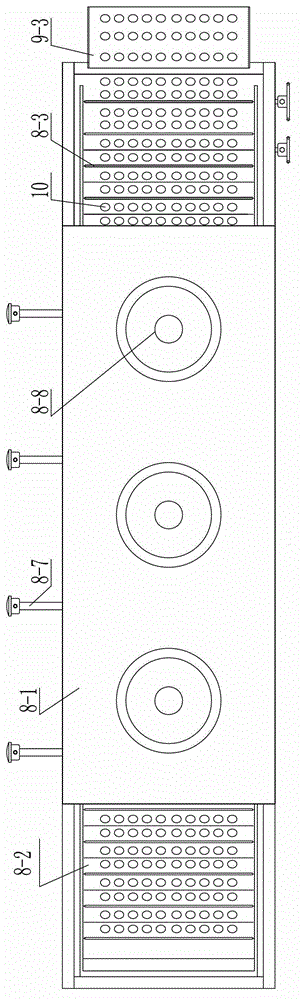

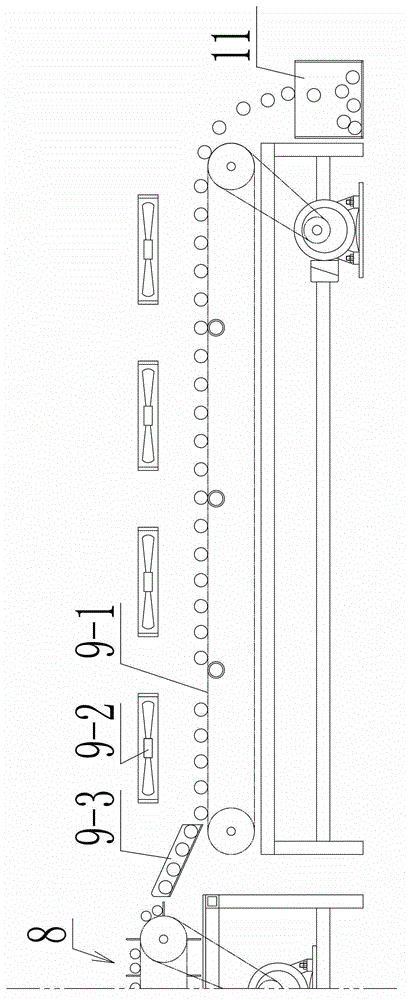

[0029] like Figure 1 to Figure 15 Shown is a schematic diagram of an embodiment of a continuous egg baking production machine provided by the present invention.

[0030] A continuous egg baking production machine is characterized in that it includes a baking equipment 8; the baking equipment 8 includes a baking conveyor line, a baking heat preservation cover 8 that is placed outside part or all of the baking conveyor line -1 and more than one set of baking heating components located in the baking heat preservation cover 8-1 and arranged along the conveying direction of the baking conveying line.

[0031] The baking conveyor line includes a baking conveyor belt or chain 8-2 and baking push plates 8-2 arranged at intervals on the baking conveyor belt or chain 8-2 along the conveying direction of the baking conveyor be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com