Automatic bread production equipment

A technology for producing equipment and bread, which is applied to dough mixers, structural components of mixing/kneading machines, and baking, etc., can solve problems such as low bread making efficiency and accidental injury to workers in ovens.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

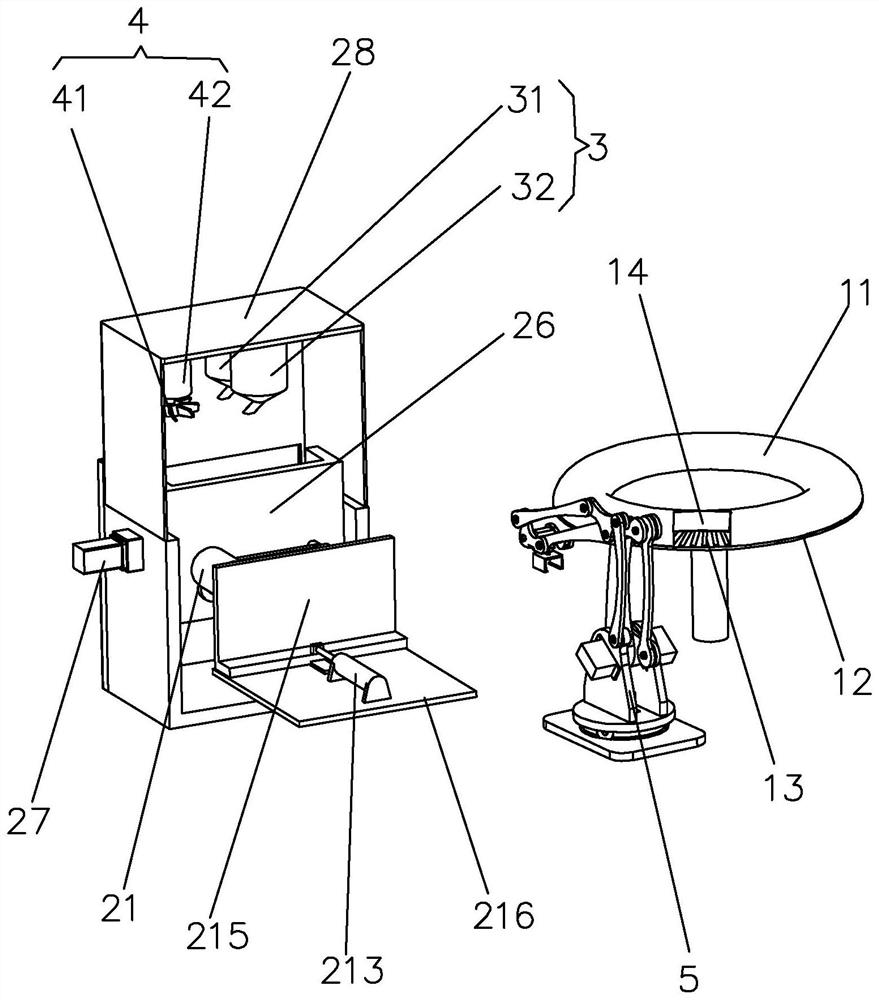

[0032] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

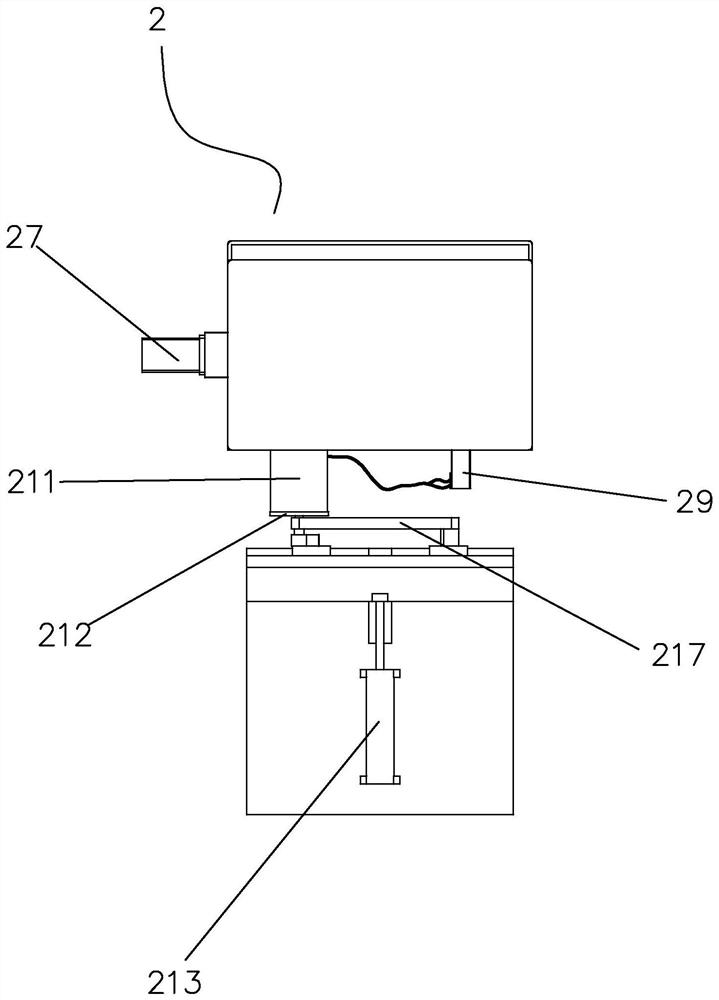

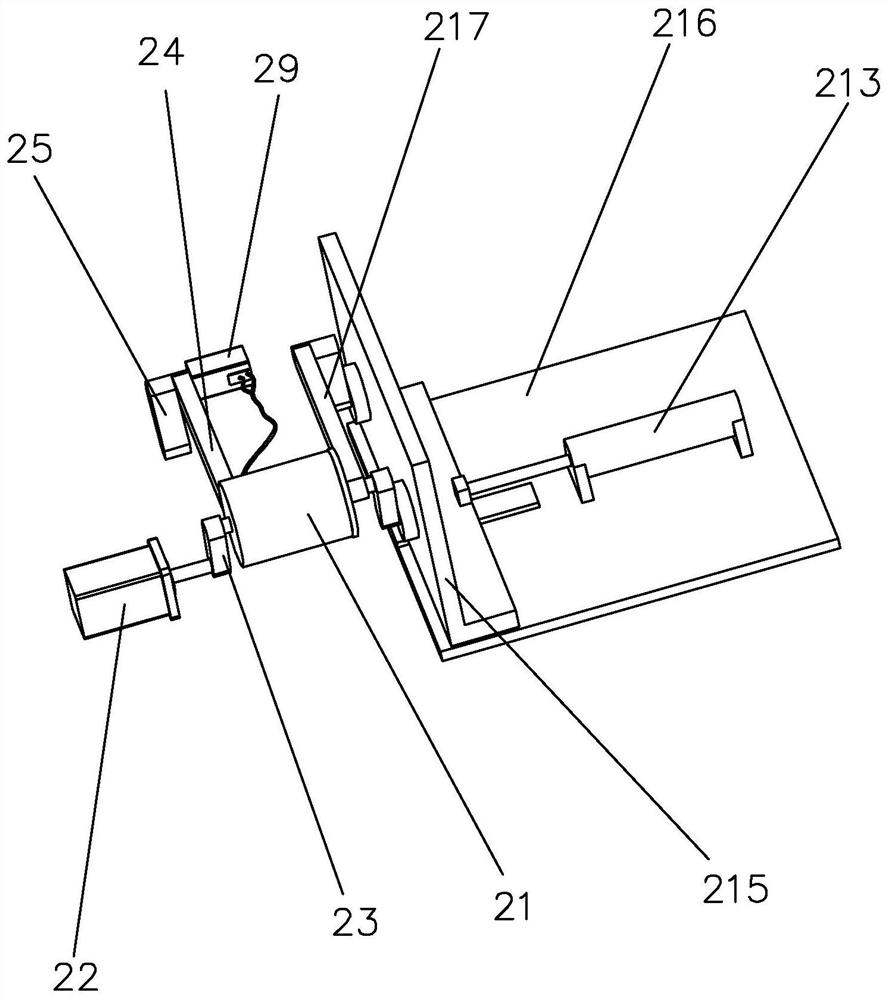

[0033] Such as Figure 1-4 Shown, a kind of automatic bread production equipment, comprises kneading device, and the baking device 1 that kneads the dough that bakes; The baking tray 12; the baking tunnel 11 is provided with a conveying mechanism 13 arranged along the baking tunnel 11; the baking tunnel 11 is also formed with an opening for the bread to enter and exit. The kneading device will carry out fully automatic dough kneading and kneading, and then the kneaded dough will be clamped to the baking device 1 by the manipulator 5 for baking. The tunnel 11 is provided with a conveying mechanism 13 arranged along the baking tunnel 11. When the dough is sent into the baking tunnel 11 through the opening on the baking tunnel 11, the dough is transported along the baking tunnel 11 under the conveyance of the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com