Movement mechanism with two modes

A mobile mechanism and form technology, applied in the direction of motor vehicles, transportation and packaging, can solve the problems of poor adaptability to the ground environment and the surrounding space environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

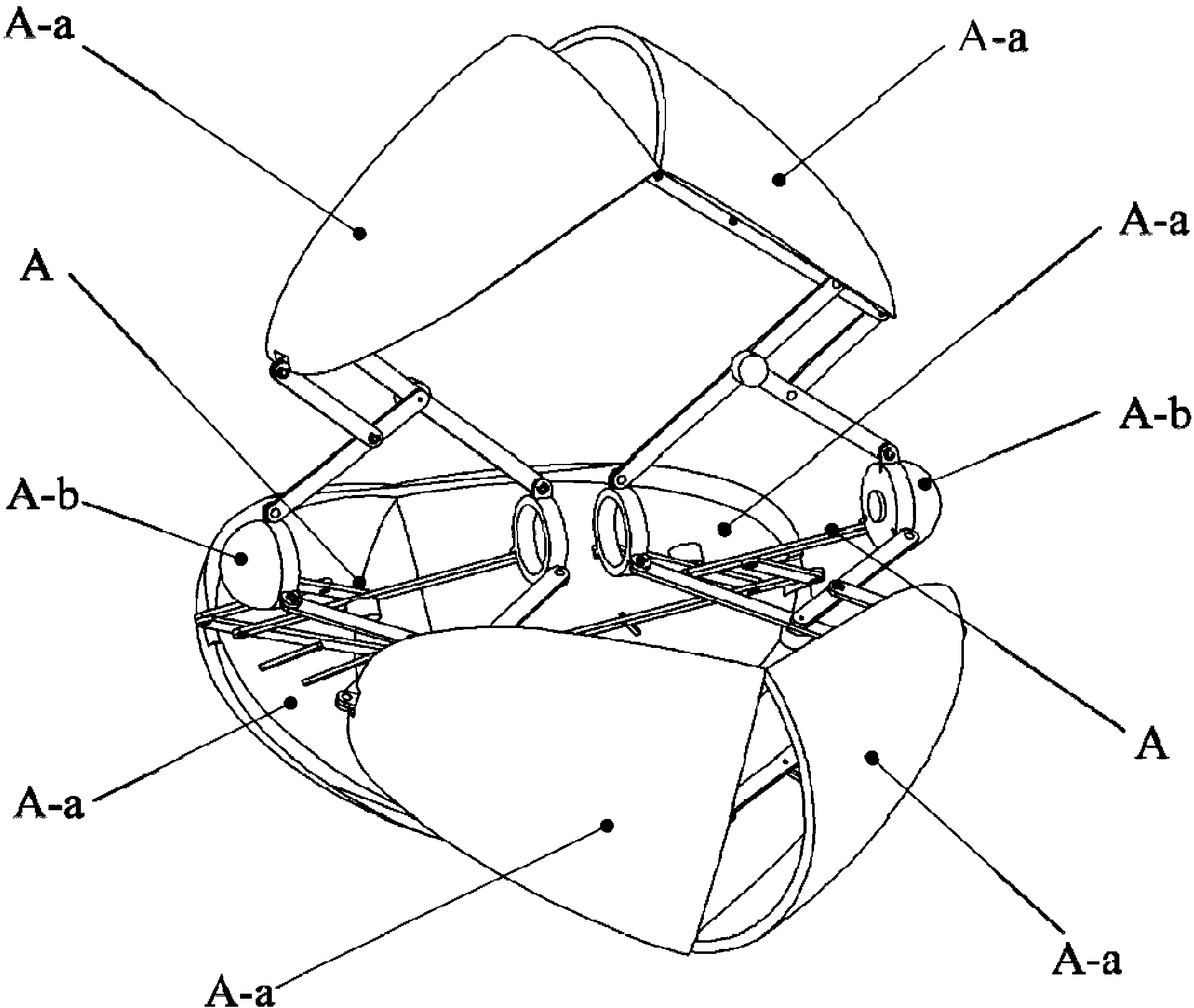

[0059] The six curved surface shells and two apex shells are fixedly connected to the outside of the two drive rod groups, which play the role of protection and movement support;

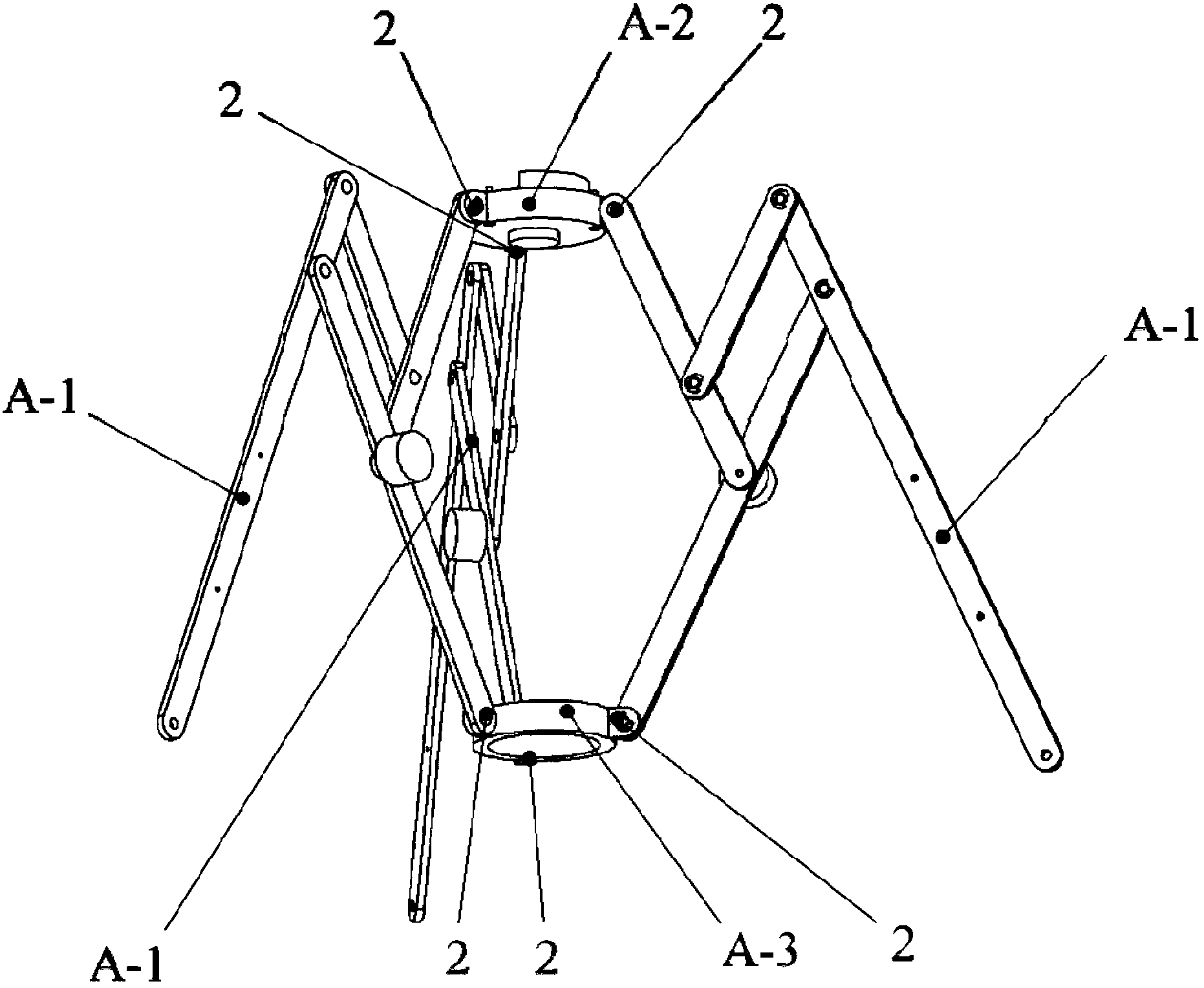

[0060] Such as image 3 , the driving rod group (A) includes three rod group branch chains (A-1), a connecting vertex (A-2), a connecting ring (A-3) and six branch chain connecting shafts (2);

[0061] Among them, the rod group branch chain (A-1) such as Figure 4, consisting of apex connecting rod (A-1-1), ring connecting rod (A-1-2), rod group connecting rod (A-1-3), auxiliary connecting rod (A-1-5), branch chain Composed of a motor (A-1-4) and three branch chains connecting the rotating shaft (2);

[0062] Such as Figure 4 , the first branch chain connects the rotating shaft (2), passes through the b hole of the apex connecting rod (A-1-1) and the a hole of the auxiliary connecting rod (A-1-5), and fixes it axially with a circlip, Make a rotation joint between the apex connecting rod (A-1-1)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com