Box sealing device of preformed packing box in automatic wrapping packing box unit

A packaging box and pre-forming technology, applied in packaging sealing/fastening, packaging, transportation packaging, etc., can solve the problems of reduced packaging efficiency, high manufacturing cost, long drop distance, etc., to improve production efficiency, save packaging time, Cleverly designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

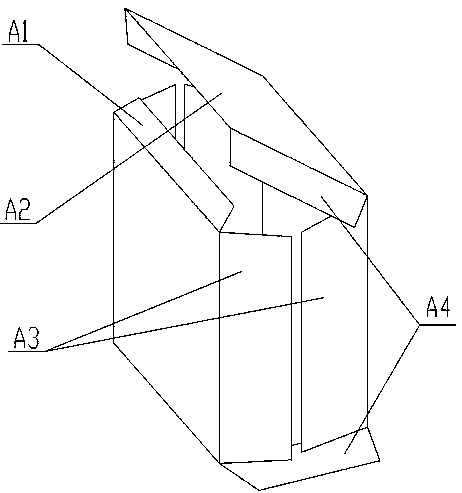

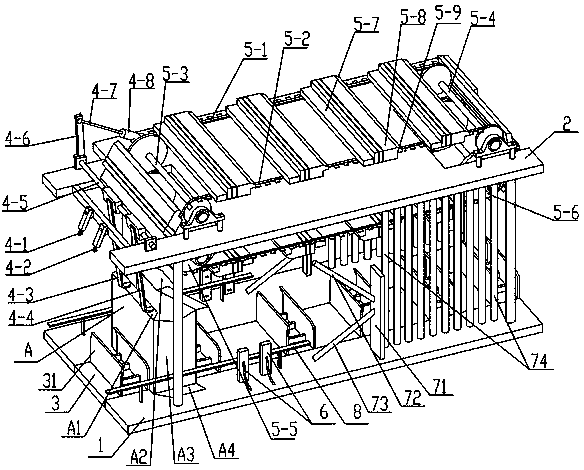

[0011] The sealing device of the preformed packaging box in the automatic box wrapping machine, the structure of the above device includes a sealing platform 1, a top plate 2 located above the sealing platform 1 and the sealing platform 1 form a double-layer frame main body, along the sealing platform 1 The transmission mechanism 3 of the preformed packaging box A is arranged longitudinally, the key is: the structure of the device also includes: the top cover sealing edge A1 glue spraying mechanism arranged on the top plate 2 along the conveying direction of the transmission mechanism 3, the circulating roller Pressure-conveying top cover A2 pressure box mechanism, left and right wing-to-wing A3 glue spraying mechanism symmetrically located on both sides of the transmission mechanism 3, and upper and lower sealing wings A4 pressure box pressure mechanism; preformed packaging box A is conveyed by means of circular rolling The top cover pressing mechanism cooperates with the sync...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com