A floating winding device and winding method thereof

A winding device and floating technology, applied in the field of rubber products, can solve the problems of uneven surface density of reinforcement layer, uneven distribution of lines, and reduce the length of equipment, so as to overcome the phenomenon of uneven winding of steel wire or wire rope and improve the surface Arrange the layout, eliminate the effect of sparse gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

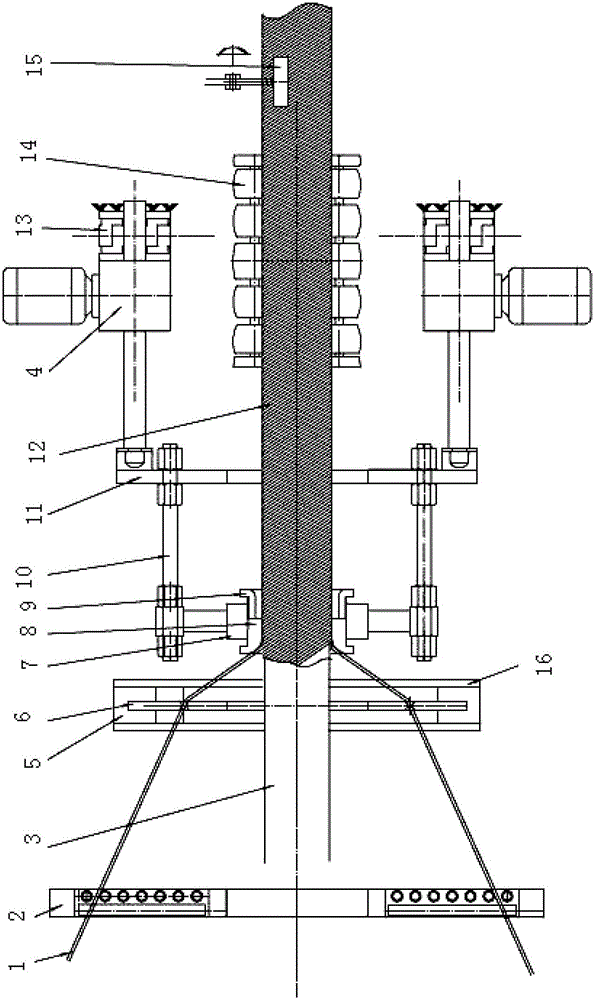

[0045] A floating winding device, comprising the following components:

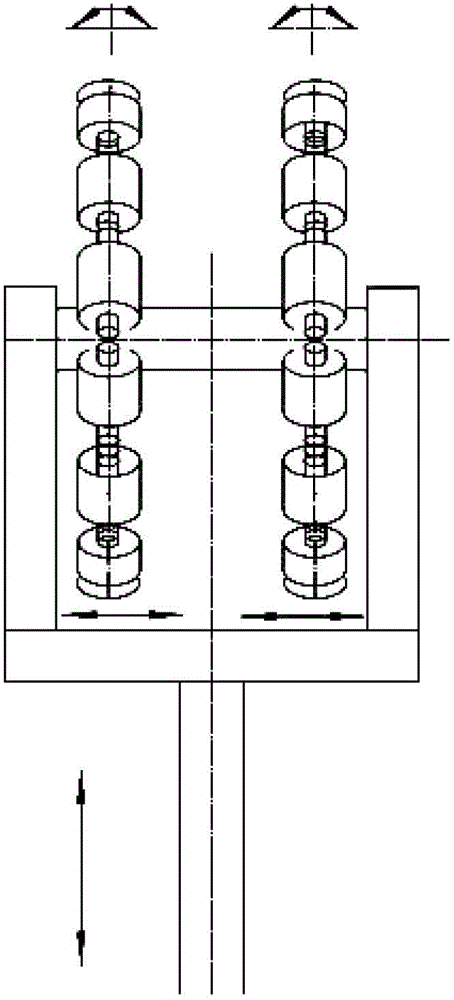

[0046] 1. The anti-friction wire guide part:

[0047] The anti-friction wire guide is composed of a frame, multiple vertical guide rollers, and multiple horizontal guide rollers. The idler rollers are installed around the frame. The frame can be fixed on the bobbin bracket or on the ground according to the process design. The combination of rollers forms a plurality of square holes, which are convenient for passing steel wires or wire ropes, so that no matter which side the wire rope touches, it can be guided to reduce wear during operation. The shape of the wire guide should be able to guide the incoming wire rope to form an arc shape entering the splitter.

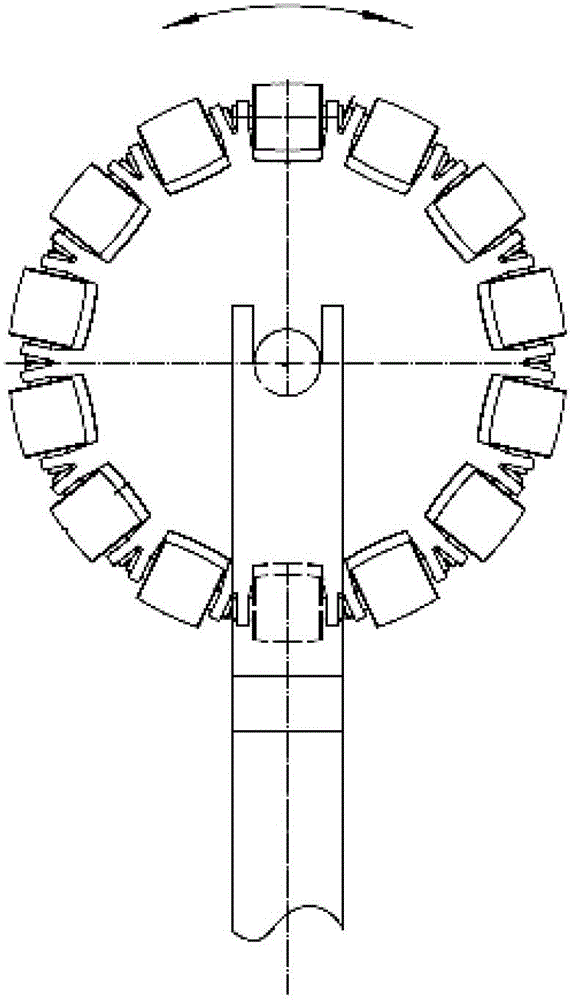

[0048] 2. The plum blossom splitter part:

[0049] The plum blossom line divider is composed of the split line plum blossom disc 6, the split line plum blossom disc seat 5 and the sliding track 16. The plum blossom disc is on a square iron plate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com