Oil well wellhead blowout preventer

A blowout prevention device and oil well technology, applied in wellbore/well components, earthwork drilling, sealing/packing, etc., can solve problems such as oil diffusion with wind, blowout accidents, environmental pollution, etc., and achieve the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to disclose the purpose, technical means and technical effects of the present invention more completely and clearly, the following is a detailed description, and please refer to the accompanying drawings and component numbers.

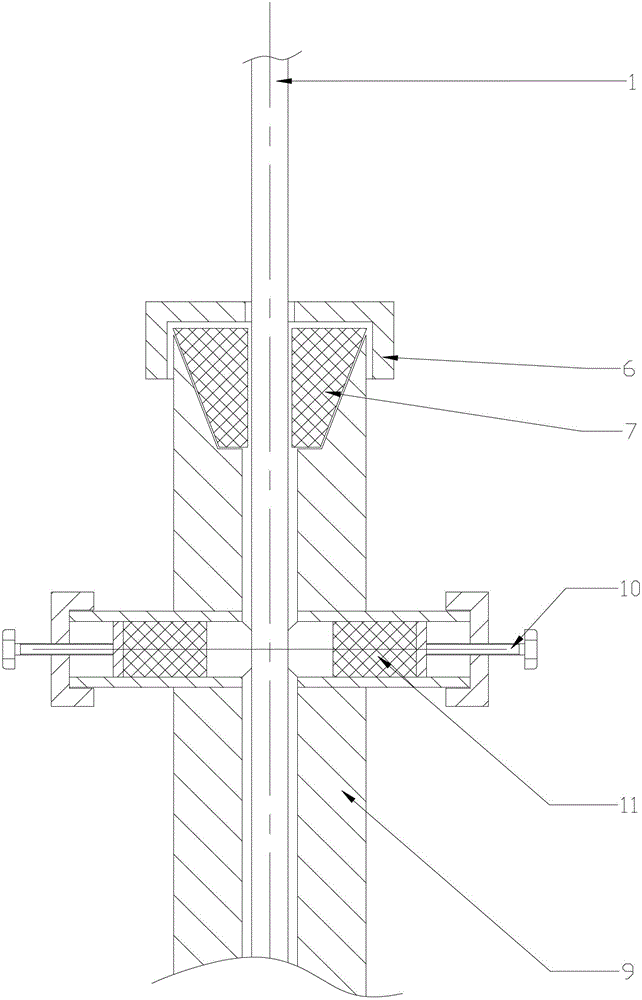

[0023] like Figure 7 As shown, the oil well wellhead blowout preventer of the present invention is applied to the oil well wellhead sealer 9 and is a passive blowout preventer. For its specific structure, please refer to Figure 2 to Figure 7 .

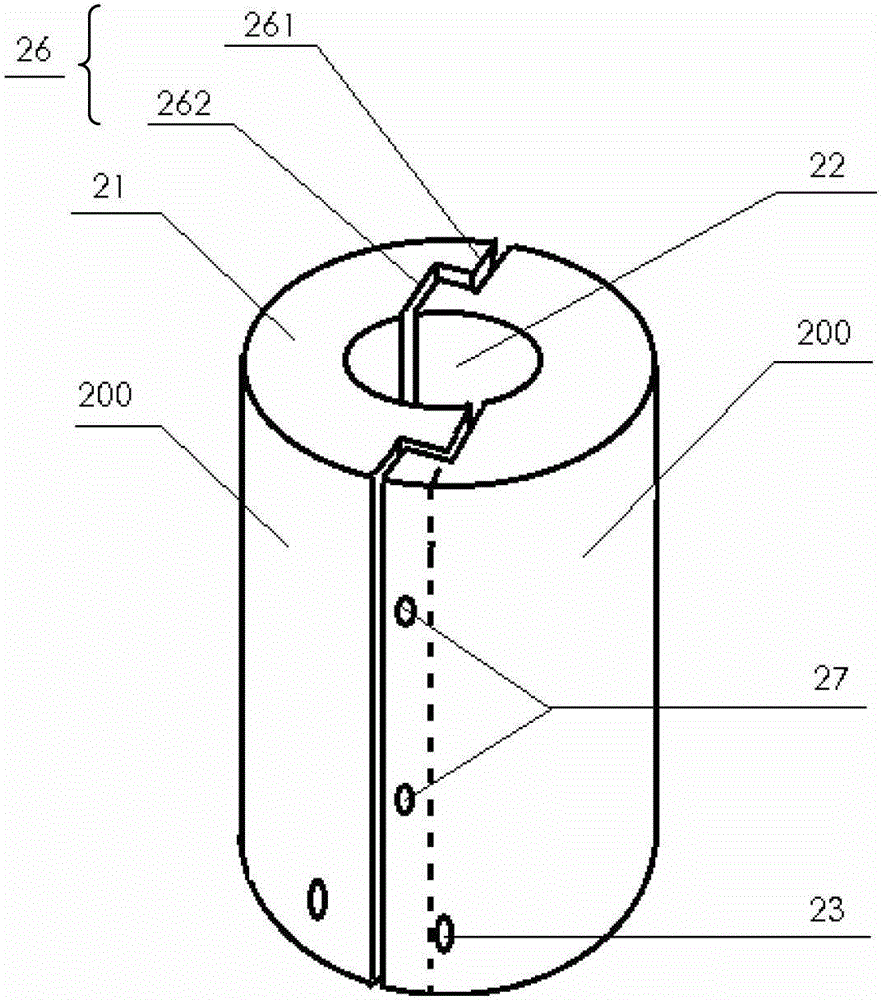

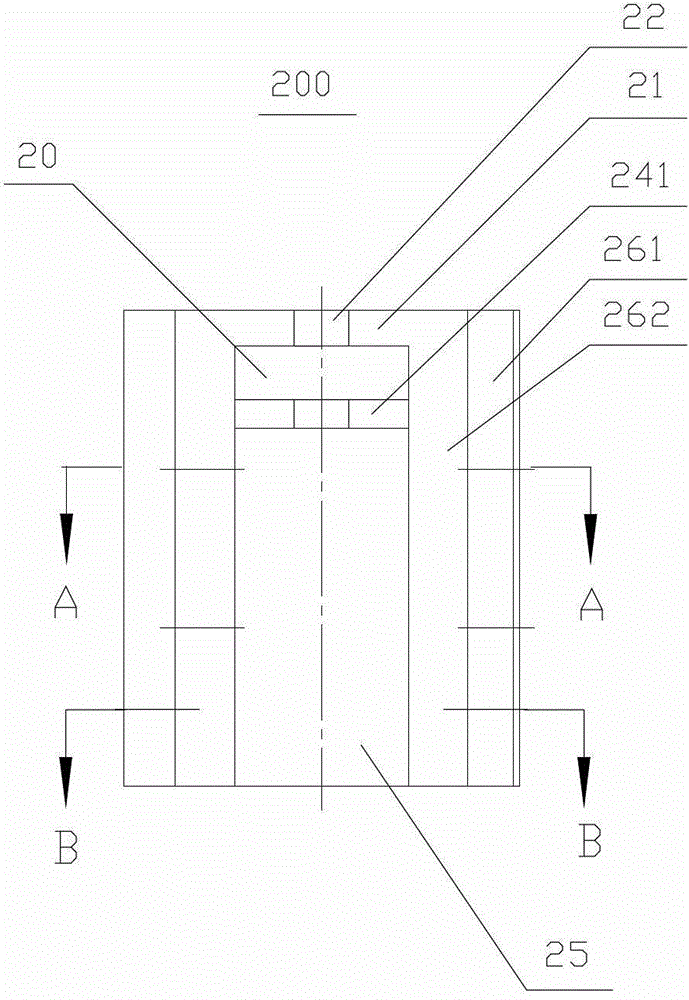

[0024] An oil well wellhead blowout prevention device, which is buckled and fixed by two half shells 200 to form a cap-shaped shell 2. The shell 2 has an integrally formed top cover 21 and a lower open cavity 25. The lower part of the shell 2 is provided with a hole for wearing Set the jacking wire 5 and fix the oil well wellhead blowout preventer to the jacking wire hole 23 on the outer peripheral side of the wellhead packing box gland 6, and there is formed between the lower part of the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com