Industrial water chilling unit

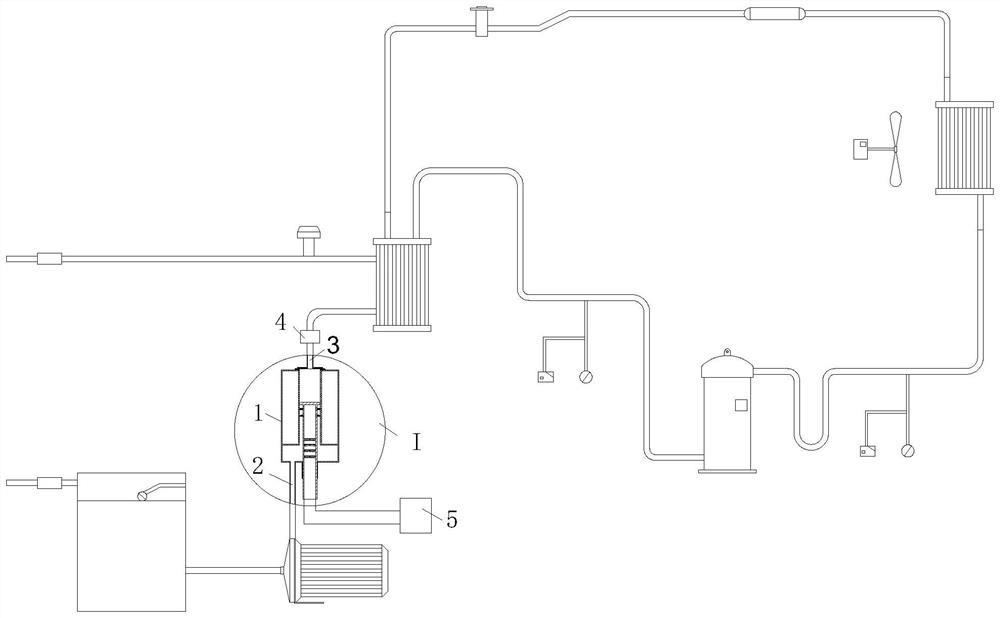

A chiller and industrial technology, applied in the direction of gravity filter, fixed element filter, filter separation, etc., can solve the problems of increased maintenance cost, blockage of cooling water circulation loop, no filter device, etc., to increase the contact area, Enhance the cleaning effect and ensure the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

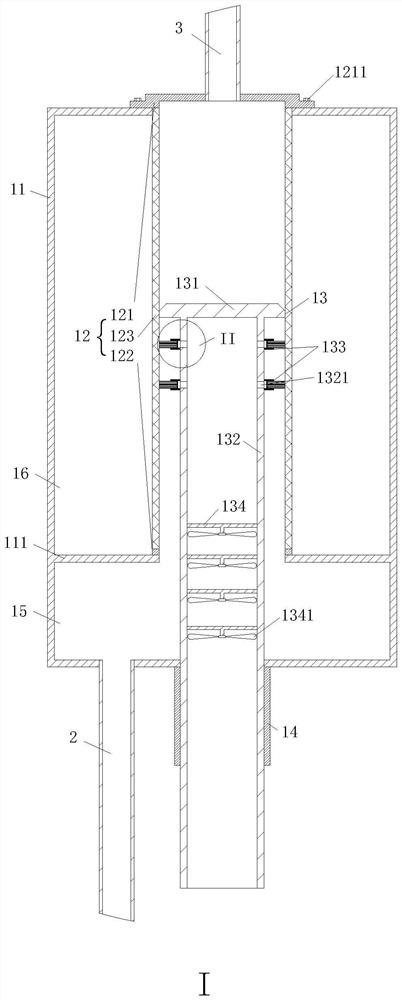

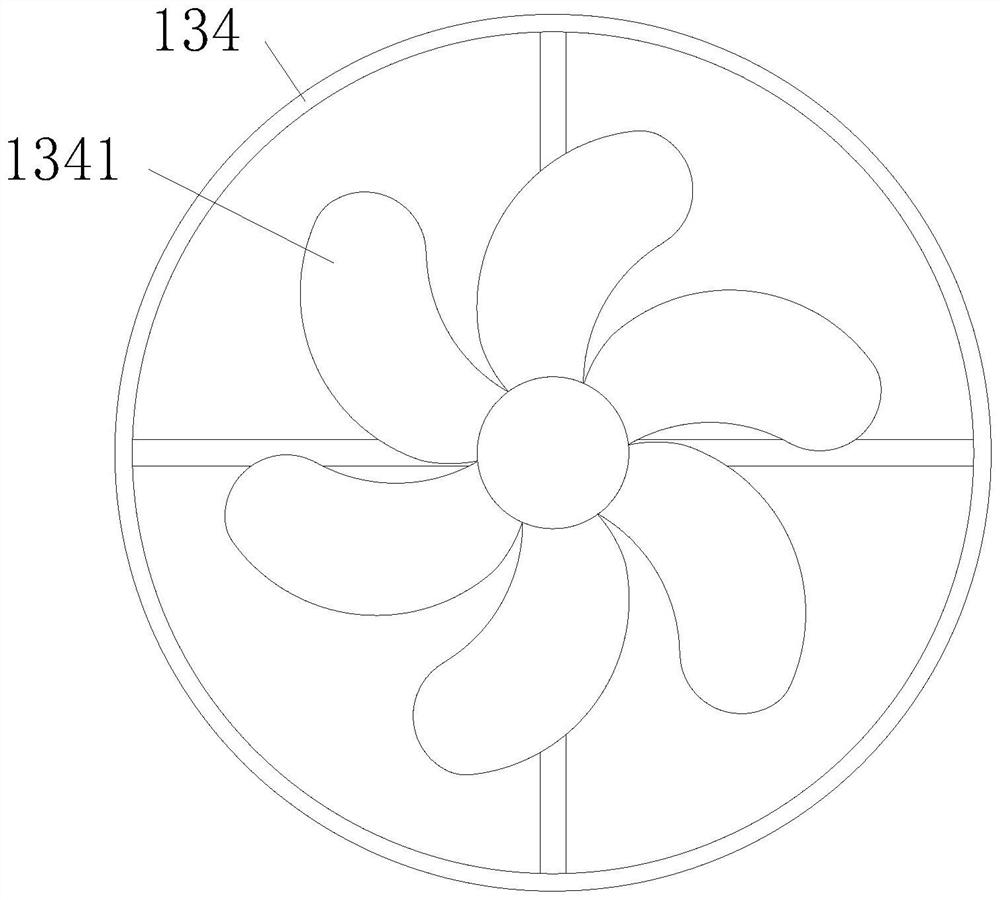

[0030] As an embodiment of the present invention, there is a protruding sleeve 14 under the housing 11, the inner wall of the sleeve 14 is in sliding and sealing connection with the outer wall of the ejector rod 132, and the retaining ring 111 and the bottom of the housing 11 form a stock solution chamber 15 , the outer side of the filter screen 123 and the inner wall of the housing 11 constitute the filtrate chamber 16 .

[0031] There is a raised sleeve 14 under the shell 11, and the top column 13 reciprocates up and down along the sleeve 14, which increases the contact area between the top column 13 and the sleeve 14, improves the guiding effect and ensures the sealing effect at the same time, the sleeve 14 The inner wall is in sliding and sealed connection with the outer wall of the push rod 132, and the unfiltered water enters the raw liquid chamber 15 through the water inlet 2, and then enters the lower part of the filter screen 123 along the area between the filter scree...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com